30

Adjusting the Front-to-Rear

Blade Slope

Check the front-to-rear blade level any time you install the

mower. If the front of the mower is more than 5/16 in.

(7.9 mm) lower than the rear of the mower, adjust the blade

level using the following instructions:

1. Position the mower on a flat surface. Disengage the

PTO, set the parking brake, stop the engine, and remove

the key. Disconnect the spark plug wire(s) from the

spark plug(s).

2. Check the air pressure of all four tires. If needed, adjust

to the recommended inflation; refer to Tire Pressure,

page 29.

3. Check and adjust the side-to-side blade level if you

have not checked the setting; refer to Leveling the

Mower from Side-to-Side, page 29.

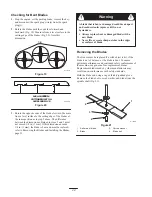

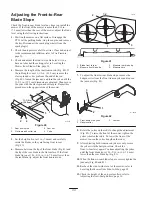

4. Measure the length of the rear trunion rod (Fig. 40). If

the rod length is not 11-1/2 in. (29.2 cm), remove the

clevis pin and cotter pin from the end of the rod

(Fig. 40), loosen the jam nut, and turn the yoke until the

11-1/2 in. (29.3 cm) dimension is obtained. Then secure

the yoke with the clevis pin and cotter pin. Repeat this

procedure on the opposite side of the mower.

2

3

m–5177

1

11-1/2 in.

(29.2 cm)

4

Figure 40

1.

Rear trunion rod

2.

Clevis pin and cotter pin

3.

Jam nut

4.

Yoke

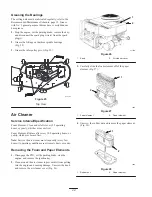

5. Set the height-of-cut at 3 in. (76 mm) and carefully

rotate the blades so they are facing front to rear

(Fig. 41).

6. Measure between the tip of the front blade (Fig. 41) and

the tip of the rear blade to the flat surface. If the front

blade tip is not 1/16–5/16 in. (1.6–7.9 mm) lower than

the rear blade tip, adjust the front trunion rods.

F ront

1078

1

2

3

4

4

Figure 41

1.

Blade front to rear

2.

Measure front blade tip

3.

Measure rear blade tip

4.

Measure here

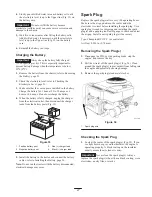

7. To adjust the front-to-rear blade slope, remove the

hairpin cotter from the front trunion yokes and loosen

the jam nuts (Fig. 42).

m–5178

1

2

3

Figure 42

1.

Front trunion rod yoke

2.

Hairpin cotter

3.

Jam nut

8. Rotate the yokes on the rods to change the adjustment

(Fig. 42). To raise the front of the mower, tighten the

yokes (shorten the rods). To lower the front of the

mower, loosen the yokes (lengthen the rods).

9. After adjusting both trunion rod yokes evenly, secure

the yokes with the hairpin cotters. Check the

front-to-rear level again. Continue adjusting the yokes

until the front blade tip is 1/16–5/16 in. (1.6–7.9 mm)

lower than the rear blade tip (Fig. 41).

10. When the front-to-rear blade slope is correct, tighten the

jam nuts (Fig. 40 and 42).

11. Recheck the side-to-side level of the mower; refer to

Leveling the Mower from Side-to-Side, page 29.

12. Check the height of the anti-scalp rollers; refer to

Adjusting the Anti-Scalp Rollers, page 16.

Summary of Contents for Z16-44 TimeCutter

Page 6: ...6 ...

Page 7: ...7 Slope Chart ...

Page 8: ...8 ...

Page 11: ...11 104 8014 1 Parking brake 104 5091 104 8088 ...

Page 38: ...38 ...

Page 39: ...39 ...