16

Activating the Battery

Bulk electrolyte with 1.265 specific gravity must be

purchased from a local battery supply outlet.

Danger

Battery electrolyte contains sulfuric acid which is a

deadly poison and causes severe burns.

•

Do not drink electrolyte and avoid contact with

skin, eyes or clothing. Wear safety glasses to

shield your eyes and robber gloves to protect

your hands.

•

Fill the battery where clean water is always

available for flushing the skin.

•

Follow all instructions and comply with all

safety messages on the electrolyte container.

1. Remove the battery from the machine; refer to

Removing the Battery, page 47.

2. Clean the top of the battery with a paper towel.

Note: Never fill the battery with electrolyte while the

battery is installed in the machine. Electrolyte could be

spilled on other parts and cause corrosion.

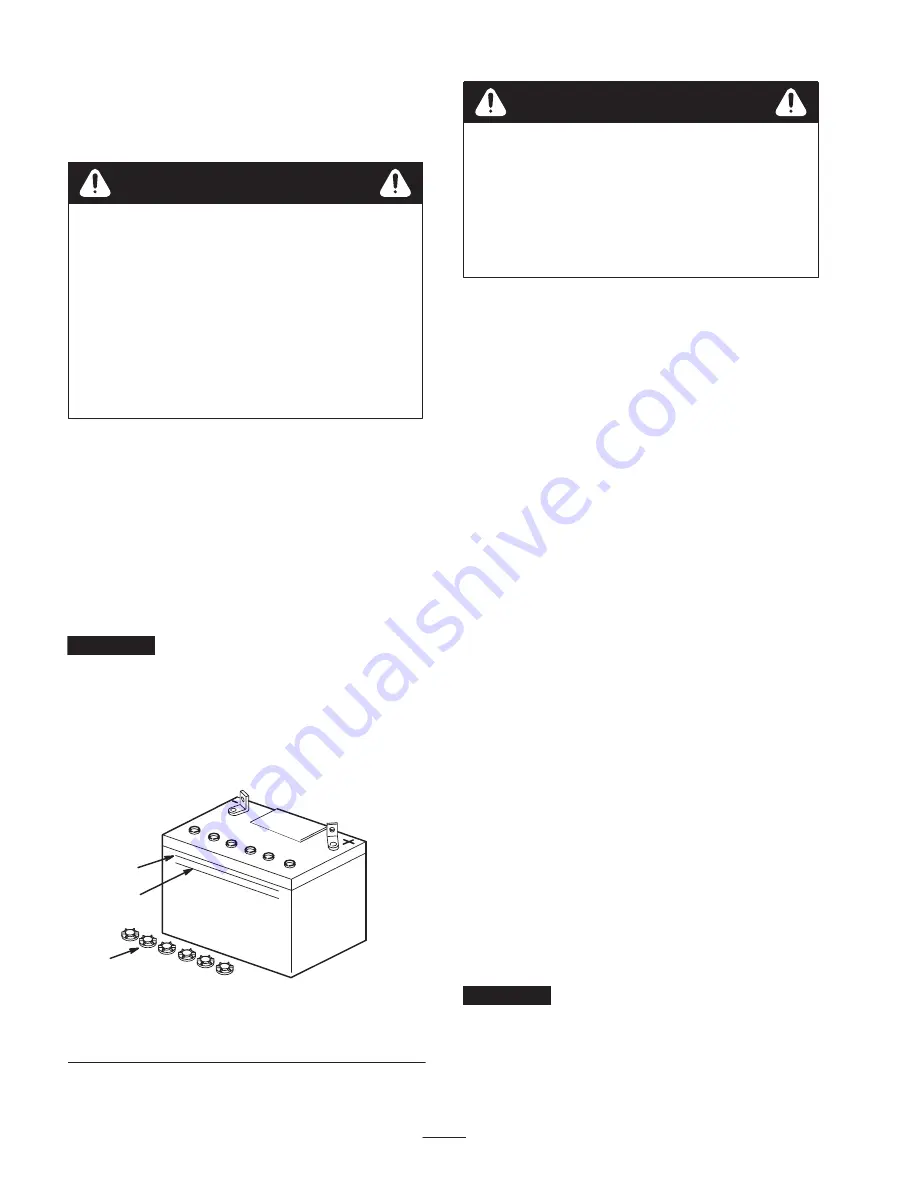

3. Remove the vent caps from the battery (Fig. 6).

4. Slowly pour electrolyte into each battery cell until the

level is up to the upper line (Fig. 6) on the battery case.

Important

Do not overfill the battery because

electrolyte (sulfuric acid) can cause severe corrosion and

damage to the chassis.

5. Wait five to ten minutes after filling the battery cells.

Add electrolyte, if necessary, until the electrolyte level

is up to the upper line (Fig. 6) on the battery case.

6. Reinstall battery filler caps.

1

2

3

m–5004

Figure 6

1.

Filler caps

2.

Upper line

3.

Lower line

Charging battery produces gasses that can explode

and cause serious injury.

•

Keep cigarettes, sparks and flames away from

battery.

•

Make sure the ignition switch is off.

•

Ventilate when charging or using battery in an

enclosed space.

Warning

7. Charge the battery; refer to Charging the Battery,

page 48.

8. Install the battery into the machine; refer to Installing

the Battery, page 47.

Note: Do not run the machine with the battery

disconnected, electrical damage may occur.

Checking the Engine Oil Level

Before you start the engine and use the machine, check the

oil level in the engine crankcase; refer to Checking the Oil

Level, page 31.

Checking the Side Discharge

Chute

Remove the plastic tie holding the side discharge chute up

and lower it into place.

Checking the Leveling of the

Mower Deck

Check the level of the deck before the machine is first put

in use.

Refer to Adjusting the Mower Level on page 42.

Checking the Radiator Coolant

Check the cooling system level before the engine is first

started.

Refer to Checking the Radiator Coolant, page 32.

Greasing the Bearings

Important

Make sure that the cutting unit spindles are

full of grease before the engine is first started.

Grease with No. 2 general purpose lithium base or

molybdenum base grease.

Summary of Contents for Z287L Z Master

Page 6: ...6 Slope Chart ...

Page 7: ...7 ...

Page 12: ...12 103 2433 106 6571 106 6570 ...

Page 55: ...55 ...