37

3. Grease the fittings on the push arms (Fig. 49).

m–5035

Figure 49

Where to Add Light Oil or Spray

Lubrication

Lubricate the machine in the following areas with spray

type lubricant or light oil. Lubricate every 160 hours.

•

Seat switch actuator

•

Brake handle pivot

•

Brake rod bushings

•

Motion control bronze bushings

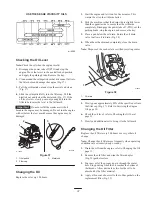

Checking the Tire Pressure

Maintain the air pressure in the front and rear tires as

specified. Uneven tire pressure can cause uneven cut.

Check the pressure at the valve stem after every 50

operating hours or monthly, whichever occurs first

(Fig. 50). Check the tires when they are cold to get the most

accurate pressure reading.

Pressure: 13 psi (90 kPa) drive wheels and caster wheels

1

m–1872

Figure 50

1.

Valve stem

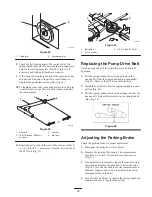

Servicing the Hydraulic System

Checking the Hydraulic Fluid

Check the hydraulic fluid level before engine is first

started.

Check the hydraulic fluid level after first 8 operating hours.

Check the hydraulic fluid level after every 25 operating

hours.

Fluid Type: Mobil 1 15W-50 synthetic motor oil or

equivalent synthetic oil.

Important

Use the oil specified or equivalent. Other

fluids could cause system damage.

Hydraulic System Oil Capacity: 67 oz. (2 l)

Note: There are two ways of checking the hydraulic oil.

One is when the oil is warm and one is when the oil is cold.

The baffle inside the tank has two levels depending if the

oil is warm or cold.

1. Position the machine on a level surface and set the

parking brake.

2. Clean the area around the filler neck of the hydraulic

tank (Fig. 51).

3. Remove the cap from the filler neck. Look inside to

check if there is fluid in the reservoir (Fig. 51).

4. If there is no fluid, add fluid to the reservoir until it

reaches the cold level of the baffle.

5. Run the machine at low idle for 15 minutes to allow any

air to purge out of the system and warm the fluid; refer

to Starting and Stopping the Engine, page 19.

6. Recheck the fluid level while the fluid is warm. If

required, add fluid to the reservoir until it reaches the

hot level of the baffle.

Note: The fluid level should be to the top of the hot level

of the baffle, when the fluid is warm (Fig. 51).

7. Install the cap on the filler neck.

3

1

2

4

m–5615

Figure 51

1.

Cap

2.

Baffle

3.

Cold fluid level—full

4.

Hot fluid level—full

Summary of Contents for Z287L Z Master

Page 6: ...6 Slope Chart ...

Page 7: ...7 ...

Page 12: ...12 103 2433 106 6571 106 6570 ...

Page 55: ...55 ...