39

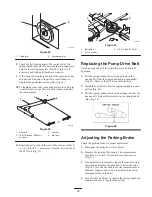

Bleeding the Hydraulic System

The traction system is self bleeding; however, it may be

necessary to bleed the system if the fluid is changed or after

work is performed on the system.

1. Raise the rear of the machine so that the wheels are off

of the ground and support it with jack stands.

2. Start the engine and run it at idle speed. Engage the

traction on one side and spin the wheel by hand.

3. When the wheel begins to spin on its own, keep it

engaged until the wheel drives smoothly (minimum

2 minutes).

4. Check the hydraulic fluid level as it drops and add as

required to maintain the proper level.

5. Repeat this procedure on the opposite wheel.

Checking the Hydraulic Lines

After every 100 operating hours, check the hydraulic lines

and hoses for leaks, loose fittings, kinked lines, loose

mounting supports, wear, weather and chemical

deterioration. Make necessary repairs before operating.

Note: Keep the areas around the hydraulic system clean

from grass and debris buildup.

Hydraulic fluid escaping under pressure can

penetrate skin and cause injury.

•

If hydraulic fluid is injected into the skin it must

be surgically removed within a few hours by a

doctor familiar with this type of injury.

Gangrene may result if this is not done.

•

Keep body and hands away from pin hole leaks

or nozzles that eject high pressure hydraulic

fluid.

•

Use cardboard or paper to find hydraulic leaks.

•

Safely relieve all pressure in the hydraulic

system before performing any work on the

hydraulic system.

•

Make sure all hydraulic fluid hoses and lines are

in good condition and all hydraulic connections

and fittings are tight before applying pressure to

hydraulic system.

Warning

Adjusting the Handle Neutral

If motion control levers do not align, or move easily into

the console notch, adjustment is required. Adjust each

lever, spring and rod separately.

Note: Motion control levers must be installed correctly. See

Installing the Motion Control Levers, page 15.

1. Stop the engine, remove ignition key and tilt seat

forward.

2. Begin with either the left or right motion control lever.

3. Move lever to the neutral position but not locked

(Fig. 55).

4. Pull lever back until the clevis pin (on arm below pivot

shaft) contacts the end of the slot (just beginning to put

pressure on the spring) (Fig. 55).

5. Check where the control lever is relative to notch in

console (Fig. 54). It should be centered allowing lever

to pivot outward to the neutral lock position.

2

m–6282

1

3

Figure 54

1.

Neutral locked position

2.

Control lever

3.

Neutral potion

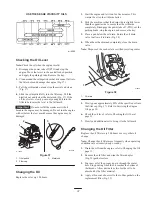

6. If adjustment is needed, loosen the nut and jam nut

against the yoke (Fig. 55).

7. Apply slight rearward pressure on the motion control

lever, turn the head of the adjustment bolt in the

appropriate direction until the control lever is centered

in neutral lock position (Fig. 54).

Note: Keeping rearward pressure on the lever will keep the

pin at the end of the slot and allow the adjustment bolt to

move the lever to the appropriate position.

8. Tighten the nut and jam nut (Fig. 55).

Summary of Contents for Z287L Z Master

Page 6: ...6 Slope Chart ...

Page 7: ...7 ...

Page 12: ...12 103 2433 106 6571 106 6570 ...

Page 55: ...55 ...