25

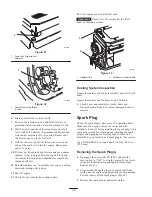

To Push the Machine

1. Disengage the power take off (PTO) and turn the

ignition key to “OFF” to stop the engine. Move levers

to neutral locked position and apply parking brake.

2. Rotate the by-pass valves counterclockwise 1 turn to

push. This allows hydraulic fluid to by-pass the pump

enabling the wheels to turn (Fig. 14).

Important

Do not rotate by–pass valves more than 1

turn. This prevents valves from coming out of the body

and causing fluid to run out.

3. Disengage parking brake before pushing.

To Operate the Machine

1. Rotate the by-pass valves clockwise 1 turn to operate

machine (Fig. 14).

Note: The machine will not drive unless by-pass valves

are turned in.

1

E

Figure 14

1.

By-pass valve

Transporting Machines

Use a heavy–duty trailer or truck to transport the machine.

Ensure that the trailer or truck has all necessary lighting

and marking as required by law. Please carefully read all

the safety instructions on pages 3–13. Knowing this

information could help you, your family, pets or

bystanders avoid injury.

To transport the machine:

•

Lock brake and block wheels.

•

Securely fasten the machine to the trailer or truck with

straps, chains, cable, or ropes.

•

Secure a trailer to towing vehicle with safety chains.

Driving on street or roadway without turn signals,

lights, reflective markings, or a slow moving

vehicle emblem is dangerous and can lead to

accidents causing personal injury.

Do not drive machine on a public street or

roadway.

Warning

Loading Machines

Use extreme caution when loading units on trailers or

trucks. One full width ramp that is wide enough to extend

beyond the rear tires is recommended instead of individual

ramps for each side of the unit. The lower rear section of

the tractor frame extends back between the rear wheels

and serves as a stop for tipping backward. Having a full

width ramp provides a surface for the frame members to

contact if the unit starts to tip backward. If it is not

possible to use one full width ramp, use enough individual

ramps to simulate a full width continuous ramp.

Ramp should be long enough so that the angles between

the ramp and the ground and the ramp and the trailer or

truck do not exceed 15 degrees. A steeper angle may

cause mower deck components to get caught as the unit

moves from ramp to trailer or truck. Steeper angles may

also cause the unit to tip backward. If loading on or near

a slope, position the trailer or truck so it is on the down

side of the slope and the ramp extends up the slope. This

will minimize the ramp angle. The trailer or truck should

be as level as possible.

Important

DO NOT attempt to turn the unit while on

the ramp; you may lose control and drive off the side.

Avoid sudden acceleration when driving up a ramp and

sudden deceleration when backing down a ramp. Both

maneuvers can cause the unit to tip backward.