43

will keep the pin at the end of the slot and allow the

adjustment bolt to move the lever to the appropriate

position).

6. Tighten nut and jam nut.

7. Repeat on opposite side of unit.

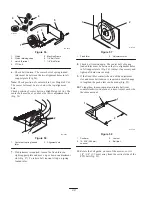

1

1

2

3

4

m–3800

3

6

5

7

Figure 46

1.

Neutral lock position

2.

Clevis pin in slot

3.

Nut

4.

Bolt

5.

Pump rod

6.

Double nuts

7.

Jam Nut

Adjusting Hydraulic Pump Neutral

Note: Adjust handle neutral first. That has to be correct

before the following adjustment can be made.

Danger

Mechanical or hydraulic jacks may fail to support

machine and cause a serious injury.

•

Use jack stand when supporting machine.

•

Do not use hydraulic jacks.

1. This adjustment must be made with drive wheels

turning. First raise the frame and block up so drive

wheels can rotate freely.

Engine must be running so motion control

adjustment can be performed. Contact with

moving parts or hot surfaces may cause personal

injury.

Keep hands, feet, face, clothing and other body

parts away from rotating parts, muffler and other

hot surfaces.

Warning

2. Slide seat forward, disconnect prop rod and tilt seat

fully forward.

3. Disconnect electrical connector from the seat safety

switch. Temporarily

install a jumper wire across

terminals in the wiring harness connector.

4. Loosen locknut at ball joint on pump control rod

(Fig. 46).

Note: The front nut of each rod has left–hand threads.

5. Start engine, open throttle 1/2 way and release parking

brake. Refer to Starting and Stopping the Engine, page

20.

6. Adjust pump rod length by rotating double nuts on rod,

in the appropriate direction, until wheel is still or

slightly creeps in reverse (Fig. 46).

7. Move motion control lever forward and reverse, then

back to neutral. Wheel must stop turning or slightly

creep in reverse.

Note: Motion control lever must be in neutral while

making any adjustments.

8. Open throttle to fast. Make sure wheel remains

stopped or slightly creeps in reverse, re-adjust if

necessary.

9. Repeat on opposite side of unit. Tighten locknuts

against ball joints.

Electrical system will not perform proper safety

shut off with jumper wire installed.

•

Remove jumper wire from wire harness

connector and plug connector into seat switch

when adjustment is completed.

•

Never operate this unit with jumper installed

and seat switch bypassed.

Warning

10. Shut off unit. Remove jumper wire from wire harness

connector and plug connector into seat switch.

11. Reinstall prop rod and lower seat.

Throttle Lever Adjustment

The tension can be adjusted by adjusting the tightness of

lever pivot bolt. Do this when needed.

1. Stop engine, remove ignition key.

2. Remove console from machine to gain access to

throttle lever.

3. Tighten nut and bolt. Test lever and adjust to desired

tension (Fig. 47).