48

1

4

m–4451

M-4373

3

2

5

7

6

6

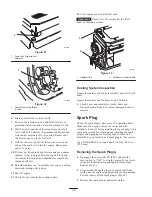

Figure 55

1.

Clutch

2.

Clutch retaining strap

3.

clutch Terminal

4.

PTO belt

5.

Machine Frame

6.

1/4’ Belt Twist

7.

1/8” Belt Twist

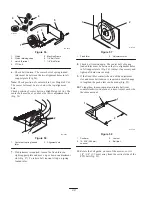

6. Check belt tension. The center bolt of spring loaded

idler must be between the two alignment holes in left

support plate (Fig 56).

Note: Check position of center bolt in Low Height of Cut.

The center bolt must be at or below the top alignment

hole.

Check position of center bolt in a High Height of Cut. The

center bolt must be at or above the lower adjustment hole

(Fig. 56).

1

2

M-4417

Figure 56

1.

Center bolt, spring loaded

idler

2.

Alignment hole

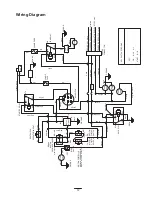

7. If adjustment is required, loosen the fixed idler on

right support plate and move up or down in adjustment

slot (Fig. 57). To relieve belt tension lift up on spring

loaded idler.

m–3746

1

2

Figure 57

1.

Fixed Idler

2.

Adjustment slot

8. Check belt tension again. The center bolt of spring

loaded idler must be between the two alignment holes

in left support plate (Fig. 56). Adjust, if necessary, and

tighten all hardware securely.

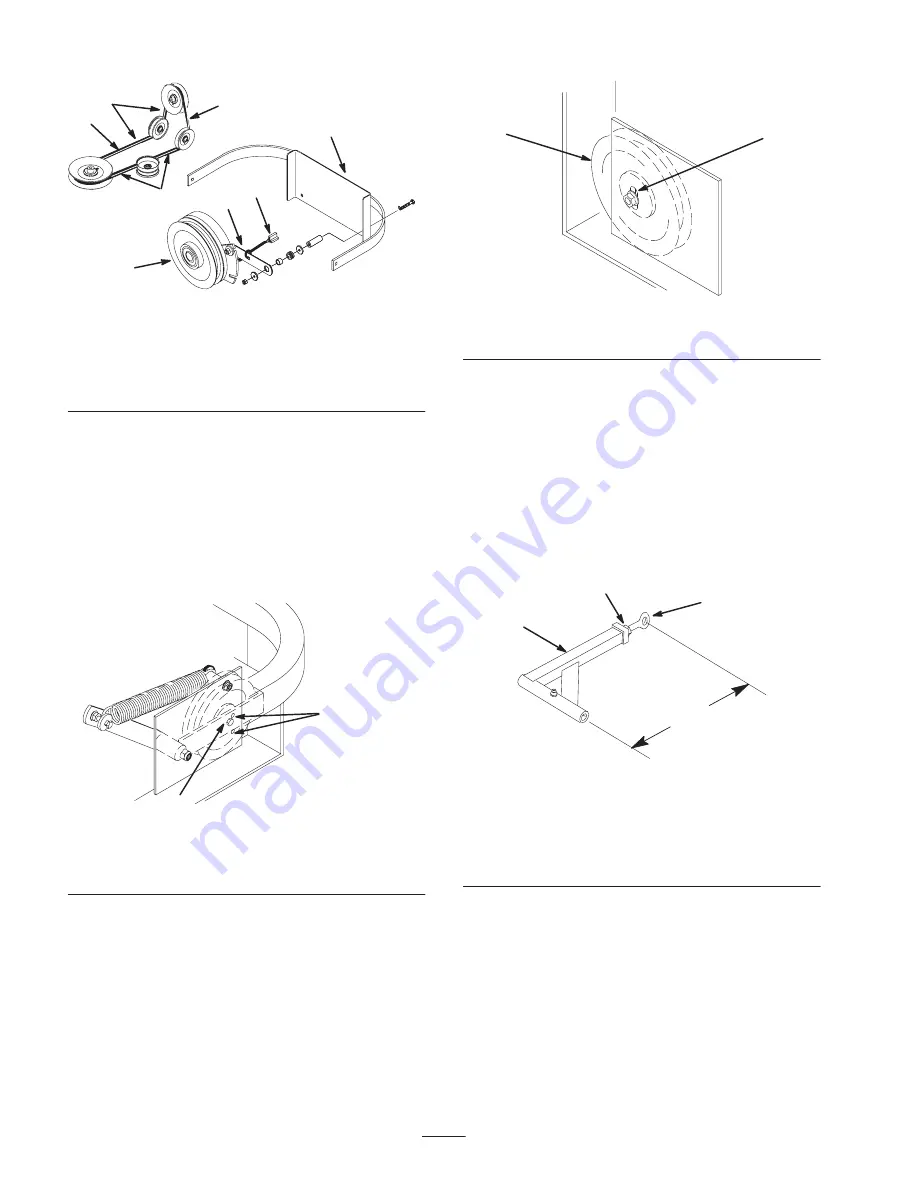

9. If the fixed idler contacts the end of the adjustment

slot and more belt tension is required, a small change

to lengthen the push arms can be made (Fig. 58).

10. To lengthen, loosen jam nut and rotate ball joint

counterclockwise, one turn at a time. Adjust each side

the same amount.

m–3740

1

3

2

1

Figure 58

1.

Push arm

2.

15–5/16” (389 mm)

nominal

3.

Jam nut

4.

Ball joint

11. Rotate the belt guide, on rear of the mower, so it is

1/8”–1/4” (3–7 mm) away from the vertical side of the

PTO belt (Fig. 59).