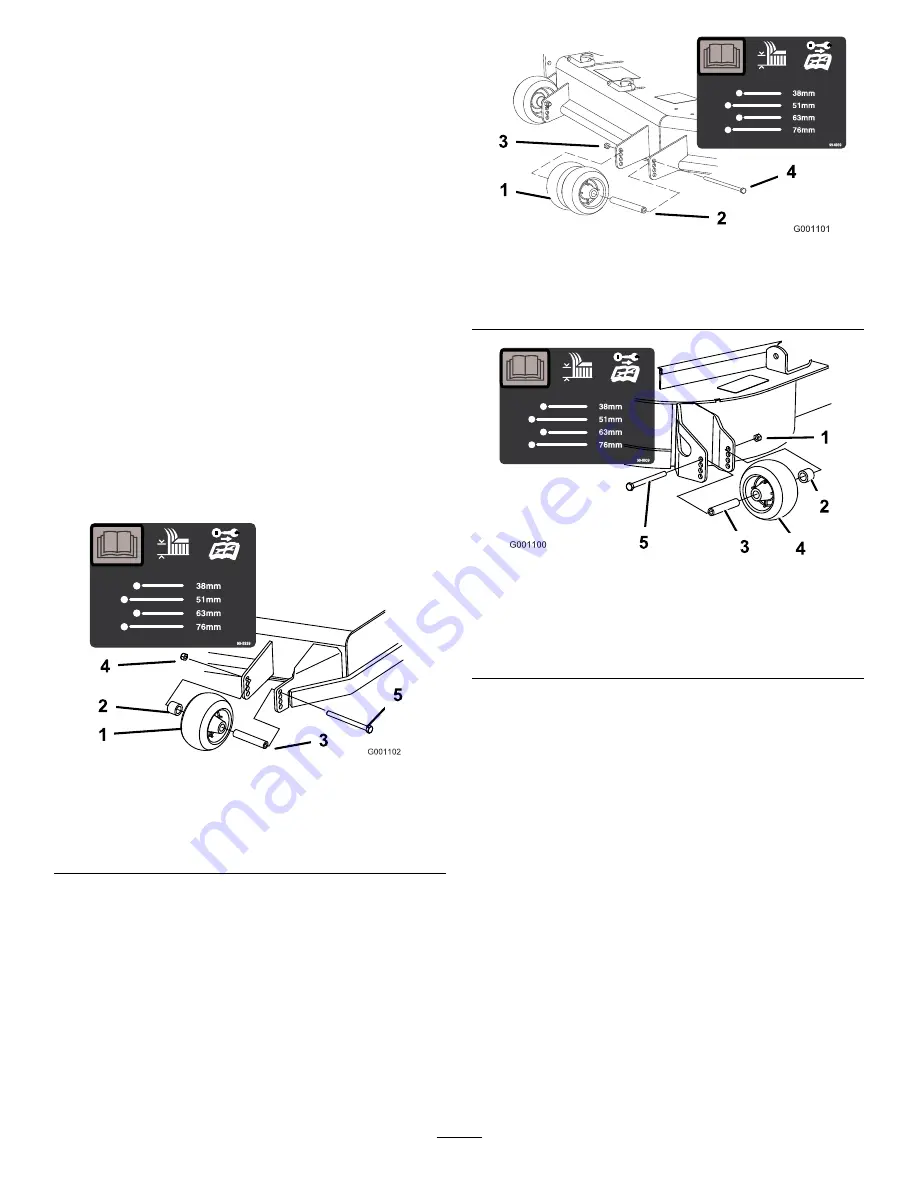

Adjusting the Anti-Scalp

Rollers

Whenever you change the height of cut, it is recommended to

adjust the height of the anti-scalp rollers.

1.

Disengage the PTO, move the motion-control levers to

the N

EUTRAL

-

LOCK

position, and engage the parking

brake.

2.

Shut off the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3.

After adjusting the height of cut, adjust the rollers by

removing the flange nut, bushing, spacer, and bolt

(

, and

Note:

The 2 middle rollers do not have a spacer

).

4.

Select a hole so that the anti-scalp roller is positioned

to the nearest corresponding height of cut desired.

5.

Install the flange nut bushing, spacer, and bolt. Torque

the bolt to 54 to 61 N∙m (40 to 45 ft-lb) (

,

, and

).

6.

Repeat this adjustment on the other anti-scalp rollers.

g001102

Figure 31

1.

Anti-scalp roller

4.

Flange nut

2.

Spacer

5.

Bolt

3.

Bushing

g001101

Figure 32

1.

Anti-scalp roller

3.

Flange nut

2.

Bushing

4.

Bolt

g001100

Figure 33

1.

Flange nut

4.

Anti-scalp roller

2.

Spacer

5.

Bolt

3.

Bushing

Adjusting the Flow Baffle Cam

Locks

This procedure is applicable only to machines with the

flow-baffle locks. Certain models have nuts and bolts in place

of the flow-baffle locks and can be adjusted the same.

You can adjust the mower-discharge flow for different types

of mowing conditions. Position the cam locks and baffle to

give the best quality of cut.

1.

Disengage the blade-control switch (PTO), move the

motion-control levers to the N

EUTRAL

-

LOCK

position,

and engage the parking brake.

2.

Shut off the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

3.

To adjust the cam locks, swing the lever up to loosen

the cam lock (

4.

Adjust the baffle and cam locks in the slots to the

desired discharge flow.

28

Summary of Contents for Z593-D Z Master 74264TE

Page 75: ...Schematics g012068 g012068 Wire Diagram Rev A 75 ...

Page 76: ...Notes ...

Page 77: ...Notes ...

Page 78: ...Notes ...