Drive System

Maintenance

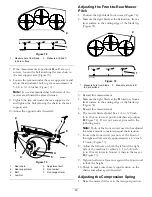

Adjusting the Tracking

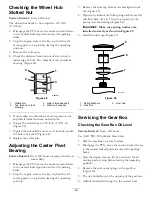

The machine has a knob for adjusting the tracking

located under the seat.

Important:

Adjust the handle neutral and hydraulic

pump neutral before adjusting the tracking. Refer

to Adjusting the Handle Neutral in Controls System

Maintenance , page 47 and Adjusting the Hydraulic

Pump Neutral in Hydraulic System Maintenance ,

page 48.

1. Push both control levers forward the same distance.

2. Check if the machine pulls to one side. If it does,

stop the machine and set the parking brake.

3. Unlatch the seat and tilt the seat forward to access

the tracking knob.

Note:

Determine the left and right sides of the

machine from the normal operating position.

4. To make the machine go right, turn the knob towards

the rightside of the machine. Refer to Figure 46.

5. To make the machine go left, turn the knob towards

the leftside of the machine. Refer to Figure 46.

6. Repeat adjustment until the tracking is correct.

G001070

2

3

1

4

5

Figure 46

1.

Tracking knob

4.

Turn this way to track right

2.

Hydraulic tank

5.

Turn this way to track left

3.

Hydraulic pumps

Checking the Tire Pressure

Service Interval:

Every 50 hours (or monthly, which

ever comes first).

Maintain the air pressure in the rear tires at 13 psi (90

kPa). Uneven tire pressure can cause uneven cut. Check

the tires when they are cold to get the most accurate

pressure reading.

Note:

The front tires are semi-pneumatic tires and do

not require air pressure maintenance.

G001055

Figure 47

39