Checking the Engine Oil Level

Service Interval:

Before each use or daily

Note:

Check the oil when the engine is cold.

1. Disengage the PTO, move the motion control levers

to the neutral locked position and set the parking

brake.

2. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

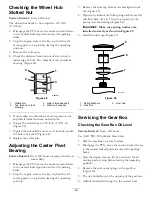

3. Clean around the oil dipstick (Figure 34) so dirt

cannot fall into the filler hole and damage the engine.

4. Pull the oil dipstick out and wipe the metal end clean

5. Slide the oil dipstick fully into the filler tube. Pull the

dipstick out and look at the metal end (Figure 34). If

the oil level is low, slowly pour only enough oil into

the fill hole to raise the level to the full mark.

Important:

Do not overfill the crankcase with

oil because this may cause engine damage. Do

not run the engine with oil below the low mark

because the engine may be damaged as a result.

G001057

1

2

3

Figure 34

1.

Oil dipstick

3.

Rear left side of machine

2.

Metal end

Changing the Engine Oil

Service Interval:

After the first 50 hours

Every 100 hours

1. Start the engine and let it run for five minutes. This

warms the oil so it drains better.

2. Park the machine on a level surface.

3. Disengage the PTO, move the motion control levers

to the neutral locked position and set the parking

brake.

4. Stop the engine, remove the key, and wait for all

moving parts to stop before leaving the operating

position.

5. Place a pan below the oil drain. Remove the drain

plug and let the oil drain completely (Figure 35).

6. Remove the oil filler cap from the top of the engine

(Figure 37). This will help the oil to drain.

7. Install the drain plug and tighten it to 25-1/2 ft-lb

(35 N•m).

Note:

Dispose of the used oil at a recycling center.

1

G001058

2

Figure 35

1.

Back of machine

2.

Drain plug

Adding Engine Oil

1. Tilt the seat forward and remove the front engine

panel (Figure 36).

33