11

nuts on this roller bearing (Fig 8c). After tightening the side roller, the spacer block should be snug with

resistance when removing it but not so tight as it is difficult to remove. With both ½” spacers

still in place, and

the sled still locked, follow the same procedure for the other SIDE ROLLER bearing on the other side of the sled

(Fig 8b & Fig 8c). Both spacers should now provide resistance when removing them but not so tight as to be

difficult to remove.

Now you have adjusted the operator side, sled guide rail and the 2 sled side bearings that run against the

operator side, sled guide rail. (

Be sure the Bolts on the other sled guide rail are loose

). Roll the sled back and

forth to be sure it moves freely. (Do not worry about the “play” in the sled at this point

). The (2) roller bearings

on the other side of the sled will take care of the play. Run the sled back and forth from one end of the

machine to the other a few times. The white bearing blocks inside the sled will help adjust the other sled guide

rail.

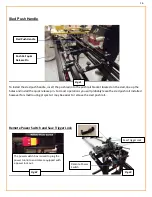

Step 3)

If you are satisfied the sled is moving freely, move on to adjusting the other sled guide rail. The

measurement between the inside

of the “operator side” sled

guide rail to the inside of the other sled guide rail

should be between 13 -

1/16” to 13

-

3/16”

(Fig 8d). There can be some variance between machines but the

important point is to be sure the measurement between the sled guide rails is the same on both ends of the

machine. If you measure 13 -

1/16”

on the inside of the guide rails on one end of the machine then the

measurement between the inside sled guide rails should be exactly 13 -

1/16” on the other end of the

machine. (

NOTE

: the corners of the sled guide rails are rounded so it is best to use a flat edge such as a steel

ruler to measure to).

With both measurements exactly the same, tighten the sled guide rail bolts on both ends

of the sled guide rail making sure the guide rail does not move while you tighten the nuts and bolts. Re-Check

your measurement after the bolts are tight. Move the sled all the way back and forth a few times to ensure

the sled is moving freely.

(NOTE: There will still be play in the sled as you move it back and forth at this point.

The next step will take care of this).

If the sled is difficult to move at one end but free on the other end then the distance between the guide rails

is not equal. Re-Check your measurement. (

NOTE: There may be slight resistance in some points while moving

the sled back and forth. This is due to the powder coating on the guide rails. The inner bearing blocks will polish

the rails as you move it back and forth over time and the resistance will even out).

To keep the guide rails clean

and polished, use a spray furniture polish or floor wax.

Measurement

adjusted to be

the same on

both ends.

Fig 8d