15

5)

With the side fence wings still clamped to the straight edge, slide the other wing lock up to the side fence wing

and tighten the wing lock bolt.

(Fig F2) (NOTE: There are 2 wing locks in total that must be tightened).

Remove the “C” clamps and the straight edge

from the side fence. Move the side fence wings back and

forth a few times. Then lock the side fence wings into the wing locks and tighten the thumb screw of

the wing lock to firmly hold the side fence wings in place. Check to be sure the side fence wings are still

in alignment with each other by placing the straight edge against the side fence wings.

6)

You can further fine tune for square to the saw blade by clamping the straight edge to the wings as

before and loosen only both wing locking bolts. For slight adjustments you can square the wings to the

saw blade. Then slide the wing locks back up to the wings and tighten the wing lock bolts that hold the

wing lock assy to the clamp rail of the Pro-Cut 50 frame.

7)

Now that the side fence is exactly square to the saw blade, check to be sure the saw blade is running

“true”.

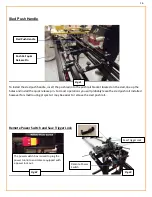

Show in Fig. 8g

, the saw bade is “not true” and adjustment

is required.

To adjust the saw blade for “

true

”,

loosen the (4) bolts that fasten the saw to the insert plate. With the

bolts loose

and the “T” Square in place

against the side fence, move the saw until the flat of the saw

blade is flat to the “T” Square, bring

ing

the saw blade to “True”. Tighten the saw mounting bolts.

This completes the set-up and alignment procedure. You should make a few test cuts to test your

set-up.

Fig 8g

Saw blade is

not flat to the

“T” square