3. Rock the ring gear back and forth to get a feel for the amount of ba klash pre ent (usually around .008).

This step will allow you to check during re-assembly that the bearing adjusters are in their correct

positions and are not one turn off. (When in doubt use a dial indicator and stand to measure the before

and after backlash).

4. Remove the adjuster locks, bearing cap bolts and caps.

5. Mark the diff rential b a ing races so that they can be re-installed on the same side.

6. Lift the differenti l case from the third member.

7. Mark the ring gear in relation to the differential case.

8. R

th ring gear

9. Remo e pinion shaft.

10. Remove he spid r gears and side gears and all thrust washers.

11. Proceed to the next section entitled Examination and Preparation of the Parts.

EXAMINATION AND PREPARATION OF THE PARTS AND THE DIFFERENTIAL CASE—ALL MODELS

EXAMINATION OF THE PARTS

1. Check the tw large side gear thrust washers for wear, cracks, warping or galling If they are not in

e cellent cond tion, replace them The small washers under the spider gears will not be used.

2. Examine the pinion shaft. If it is worn by more than .002 where the side gears were located, purchase a

new one from your dealer.

3. Check the hardness of the pinion shaft. In many instances we have found that the stock factory shaft is

somewhat soft. Try to scratch a groove in it with a file near the center. If you can do so, the shaft is

soft. If the file tends to slide and not cut, the shaft hardnes is probably ac eptable. If it is soft r place

it, and also be sure to check the new shaft. If the old shaft is worn under the spider gears, definitely

replace it.

4. Thoroughly clean the differential housi g to remove any old dirt and metal particles.

5. If the installat on is in the front d fferential, now would be the time to inspect/replace the inne axle seals.

6. Examine the differential case and earings. If there are any chips or cracks n the case, and/or the

b ar ngs are worn, replace them—but remember that the ring and pinion backlash and bearing pre-load will

need to be set up again.

7. If your differential has a thrust block and it is to be re-used (Jeep AMC-20, for example), examine the

block and be sure that it is in good condition. If it needs to be replaced, be sure to set up the axle shaft

end-play again (see your shop manual).

CHECKING CASE TOLERANCES

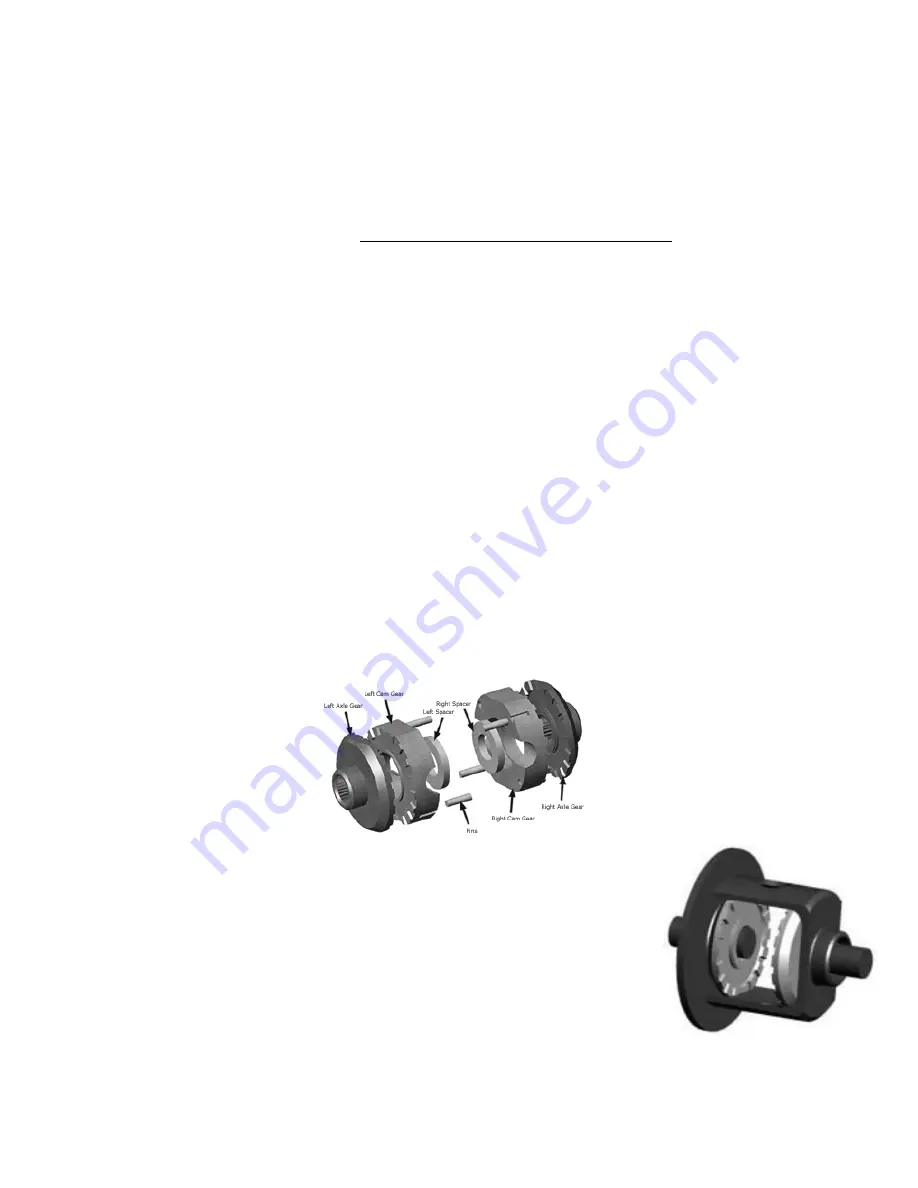

1. Apply a thin coat of medium to heavy axle grease to the teeth of the Aussie

Locker axle gears, to the back surface and around the hub in the center.

Using this grease will help with holding the parts in place later on.

2. Place a thrust washer on each axle ge r.

3. Install both axle gears in the differential case.

4. Place a spacer onto each axle gear, with th open end over the hub of

the axle gear. The grease will hold it in place.

5. Carefully slide the pinion shaft all the way into the case (past the

spacers).

6. With a screwdr ver, carefully pry apart the gap between the spacers and the pinion shaft. This step will

compress out the grease and help assure that the following measurement is accurate.

Th s tep wi l allow you o check dur ng e ass m ly t at the bearing adjusters ar n the r correct

posi ions a d are not one urn o f. (Wh n in doubt use a dial ndicato and stand o measu e the b

and after bac lash .

Remove he adjus e

5. Mark the dif erential bearing races o that th y c n be

6. Lift t e d ferentia c se from the third member.

7. Ma k the ring gear in relation to the d fferentia

8. Rem ve the r ng gear

9. Remove the pinion sh

1 Remove the spider gear

11. Proceed to the nex sect n entitled Examinat on and Preparati

exce l nt cond tion, ep ace them The small was ers nder th spider gea s w ll n t be u ed.

Examine he pinion shaft I t is worn by more than . 02 where the side ge r were l cated

new one from our deale

Che k the hardness of th

somewhat soft. Try o scratch a groove n t with a file ne r he center. If you can do so the sh ft is

soft If the file ends to slide nd not cut the sh ft ha dness is robab cceptab e f i is soft rep

it, a d also be sure to check he new shaf . f the o d shaft is worn unde the spider ear

efin tely

r

lace it.

horou h

5. If the insta ation is in the ront differential, now wou d e the t me o nspect/repla

6. Exam ne the d ffere t al case and bearings If there ar any ch ps or cracks in he case a d/or the

bearings are worn repla e th m—but reme ber that the ring and pinion backlash and b ar ng pre-l

need to be set up again

If yo r di ferentia has a

block nd be sure that i s in good condi on. If it needs to be replace , be s re to set p the axle sh

end-p ay ga n ( ee your shop manual

Locke

xle gear , to the back surface and around the hub in he center.

Using h s g ease will help with holding the parts in pla e la er on.

P ace a th u t washe on each axle ge r.

3. Insta oth ax e gear in the d fferential

4. Place spa er onto each axle gear, with the

the a l gear. he g ease wi l hold i p ace

Carefu ly slid he pinion sha t a l the ay in

spacers)

With a c

com r ss ou the g ease and he assure t at he fo low ng measurement is a cura e