11

Outdoor Unit

Installation Manual

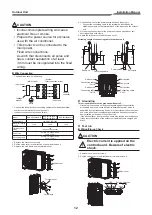

Insulation of the Refrigerant Pipes

• Insulate the refrigerant pipes for liquid and gas separately.

Heat-proof bubble polyethylene

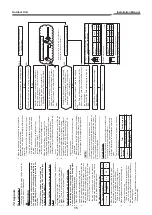

Gas Leak Inspection

• Perform a gas leak inspection for the

fl

are nut connections, valve stem

connection, and service port cap without fail.

• Use a leak detector exclusively manufactured for R32.

Flare nut connections

(Indoor unit)

Service port cap

connection

Valve stem cap

connection

* Check point example (RAS-3M18U2AVG-E)

Flare nut connections

(Outdoor unit)

Performing Additional Installation of an Indoor Unit

1. Collect refrigerant from the outdoor unit.

2. Turn off the circuit breaker.

3. Perform additional installation referring to the procedure from “Refrigerant

Piping Connection” on the previous page.

7

Electrical work

WARNING

• Be sure to comply with local regulations/

codes when running the wire from the

outdoor unit to the indoor unit.

(Size of wire and wiring method etc.)

• A lack of electrical capacitance or

incorrect wiring may cause an electric

shock or a

fi

re.

• To make sure that the wiring connection

are secure, use designated cables.

• Fix the cables securely so that no

external force applied to the cables may

effect the terminals.

• If wiring connections are incomplete

or cables are not

fi

xed securely, it may

cause a

fi

re.

• Be sure to ground the outdoor unit.

• Incomplete grounding may lead to an

electric shock.

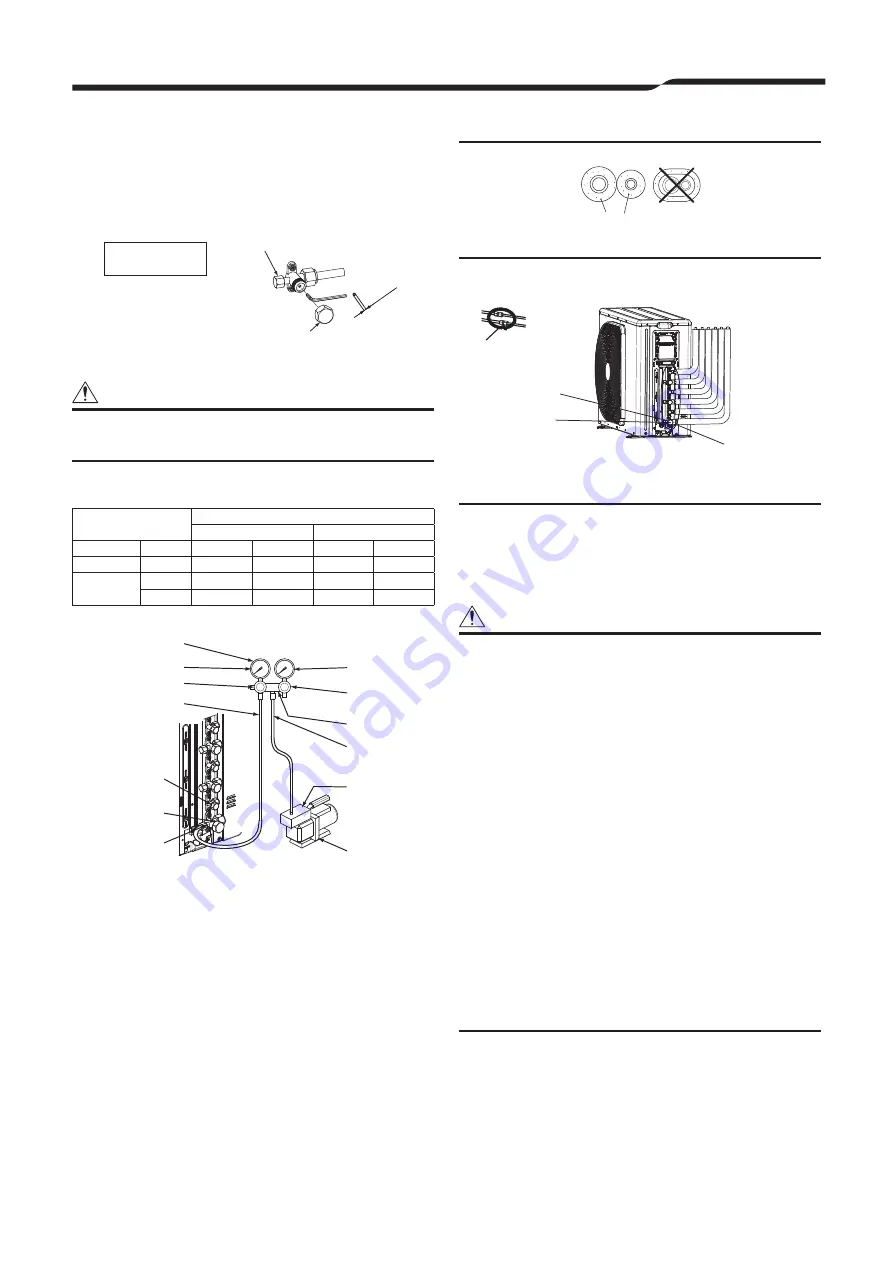

3. Close the Handle Low of the gauge manifold valve fully, then stop

operating the vacuum pump.

• Leave the gauge and pump as they are for 1 or 2 minutes, then make

sure that the compound pressure gauge reading stays at –101 kPa (–76

cmHg).

• You need not add refrigerant.

4. Disconnect the charge hose from the service port, then open the valve

stem fully using a 4 mm hexagon wrench.

Hexagon wrench is

required.

Service port cap

4 mm

Valve stem cap

5. Tighten the service valve stem cap and service port cap securely.

CAUTION

Use a torque wrench and tighten the nut at

the speci

fi

ed torque value.

6. Tighten all the caps on the valves securely, then perform a gas leak

inspection.

Service valve

Tighten torque

Valve stem cap

Service port cap

Type

mm

N•m

kgf•m

N•m

kgf•m

Liquid side

6.35

14 to 18

1.4 to 1.8

—

—

Gas side

9.52

14 to 18

1.4 to 1.8

14 to 18

1.4 to 1.8

12.7

33 to 42

3.3 to 4.2

14 to 18

1.4 to 1.8

Pressure gauge

Handle Hi

(Keep full closed)

Manifold valve

Charge hose

Vacuum pump

adapter for

counter

fl

ow

preventation

Vacuum pump

Compound

pressure gauge

–101 kPa (–76 cmHg)

Handle Low

Charge hose

Service valve at

the liquid side

Service valve at

the gas side

Service port

(Valve core

(Setting pin))

Summary of Contents for 13340

Page 17: ......