–

33

–

Item

1. Basic

operation

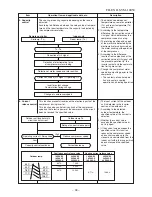

Operation flow and applicable data, etc.

1. Operation control

Receiving the user’s operation condition setup, the operation statuses of indoor/outdoor units are

controlled.

1) The operation conditions are selected by the remote controller as shown in the below.

2) A signal is sent by ON button of the remote controller.

3) The signal is received by a sensor of the indoor unit and processed by the indoor controllers as

shown in the below.

4) The indoor controller controls the indoor fan motor and louver motor.

5) The indoor controller sends the operation command to the outdoor controller, and sends/

receives the control status with a serial signal.

6) The outdoor controller controls the operation as shown in the left, and also controls the com-

pressor, outdoor fan motor, 4-way valve and pulse motor valve.

Description

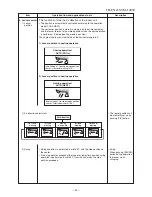

Control contents of remote controller

• ON/OFF (Air conditioner / Air purifier)

• Operation select (COOL /HEAT / AUTO / DRY)

• Temperature setup

• Air direction

• Swing

• Air volume select

(AUTO / LOW / LOW+ / MED / MED+ / HIGH)

• ECO

• COMFORT SLEEP

• ON timer setup

• QUIET

• OFF timer setup

• PRESET

• Hi-POWER

• ONE-TOUCH

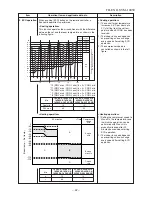

Indoor unit control

• Command signal generating function of

indoor unit operation

• Calculation function (temperature calculation)

• Activation compensation function of indoor fan

• Cold draft preventive function

• Timer function

• Indoor heat exchanger release control

• Indoor fan motor

• Louver motor

Outdoor unit control

• Frequency control of inverter output

• Waveform composite function

• Calculation function

(Temperature calculation)

• AD conversion function

• Quick heating function

• Delay function of compressor reactivation

• Current release function

• GTr over-current preventive function

• Defrost operation function

• Compressor

• Outdoor fan motor

• 4-way valve

• Pulse Motor valve

(PMV)

~

Remote controller

Indoor unit

Outdoor unit

Serial signal send/receive

Outdoor unit control

Inverter

Indoor unit control

Operation command

Serial signal send/receive

Signal receiving

Selection of

operation conditions

ON/OFF

FILE NO. SVM-10050