Summary of Contents for A03-009

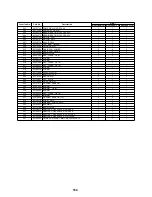

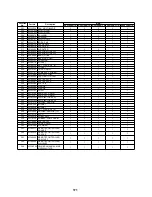

Page 149: ...148 ...

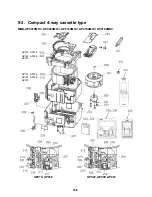

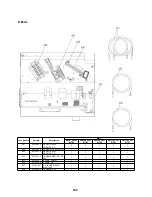

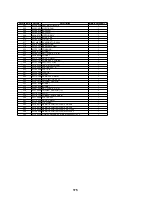

Page 153: ...152 9 2 1 Way cassette type SH AP015 AP018 AP024 ...

Page 161: ...160 9 4 Slim duct type MMD AP0074SPH AP0094SPH AP0124SPH AP0154SPH AP0184SPH ...

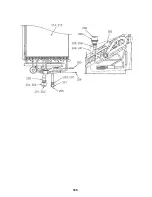

Page 165: ...164 9 5 Concealed duct standard type MMD AP0074BH AP0094BH AP0124BH AP0154BH AP0184BH ...

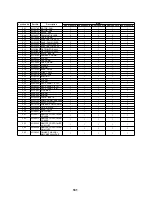

Page 166: ...165 ...

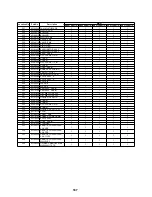

Page 169: ...168 MMD AP0244BH AP0274BH AP0304BH AP0364BH AP0484BH ...

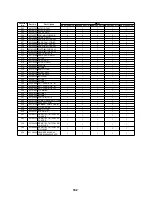

Page 170: ...169 ...

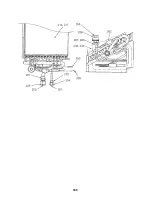

Page 173: ...172 MMD AP0564BH ...

Page 174: ...173 ...

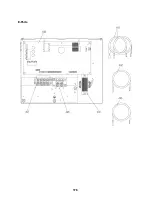

Page 177: ...176 E Parts ...

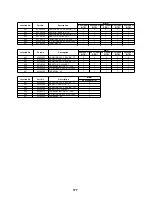

Page 179: ...178 9 6 Concealed duct high static pressure type MMD AP0184H AP0244H AP0274H AP0364H AP0484H ...

Page 183: ...182 MMD AP0724H AP0964H ...

Page 184: ...183 ...

Page 187: ...186 9 7 Ceiling type MMC AP0154H AP0184H AP0244H AP0274H ...

Page 190: ...189 MMC AP0364H AP0484H ...

Page 194: ...193 9 8 Floor standing type MMF AP0154H AP0184H AP0244H AP0274H ...

Page 195: ...194 MMF AP0154H AP0184H AP0244H AP0274H ...

Page 198: ...197 MMF AP0364H AP0484H AP0564H ...

Page 199: ...198 MMF AP0364H AP0484H AP0564H ...

Page 203: ...202 9 9 Floor standing concealed type MML AP0074BH AP0094BH AP0124BH AP0154BH AP0184BH ...

Page 206: ...205 MML AP0244BH ...

Page 209: ...208 9 10 Floor standing cabinet type MML AP0074H AP0094H AP0124H AP0154H AP0184H ...

Page 210: ...209 MML AP0074H AP0094H AP0124H AP0154H AP0184H ...

Page 213: ...212 MML AP0244H ...

Page 214: ...213 MML AP0244H ...