−

52

−

FILE NO. SVM-04007

NO

YES

YES

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

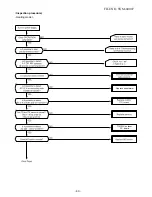

Does compressor operate?

Is compressor

turned off shortly?

Does inner

overload relay

(in compressor)

operate?

Check charged amount of refrigerant.

Check defective overload.

Check compressor.

Replace

compressor.

Replace TC

sensor.

Connect TC

sensor properly.

Is TC sensor

disconnected from

the sensing element?

Is circuit wiring

normal?

Is outdoor P.C.

board normal?

Wiring check/modification

Replace

P.C. board.

Replace

P.C. board.

Outdoor P.C. board

is defective.

Indoor P.C. board

is defective.

Is TC sensor

resistance value

(10k

Ω

at 25

°

C) normal?

Failure

[09 Other cycle error] (1) (Heat pump model)

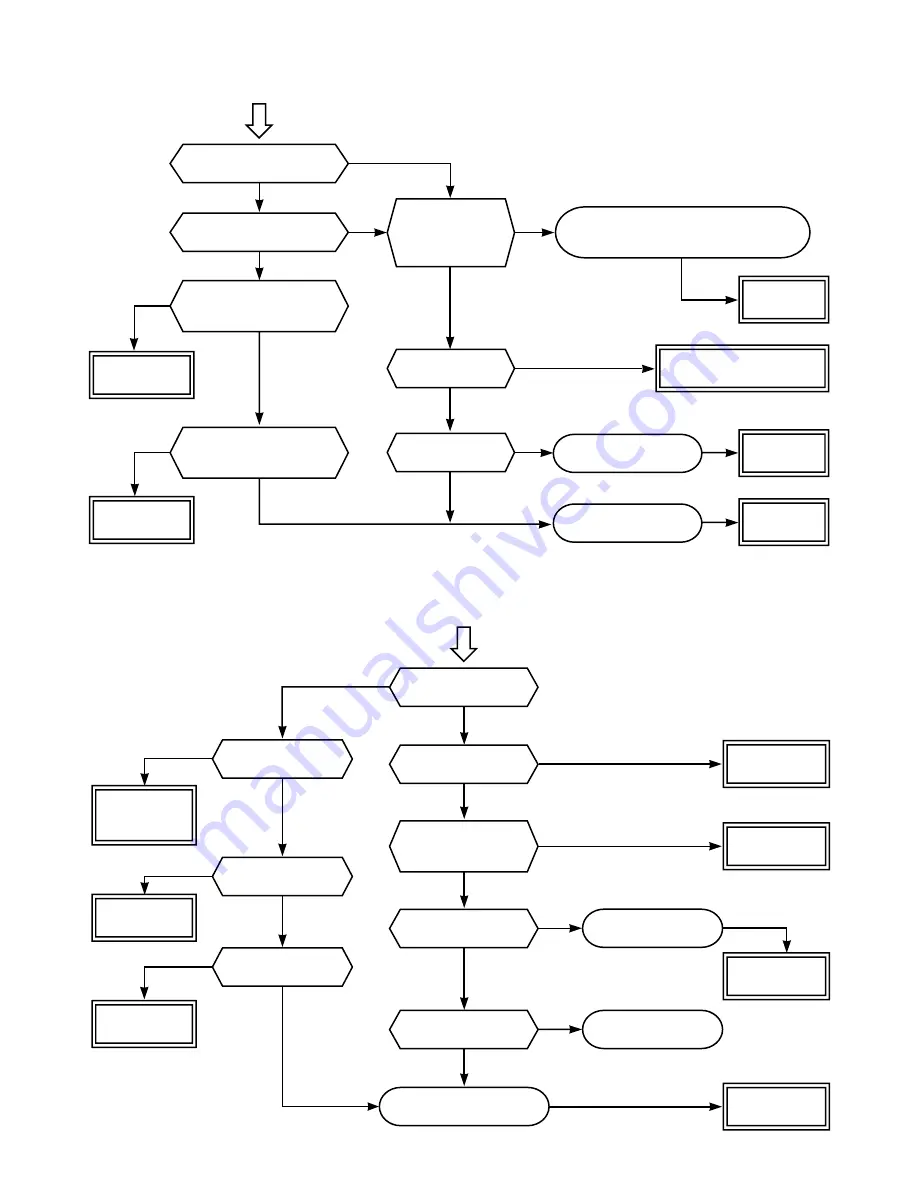

[09 Other cycle error] (2)

Clean filters.

Replace

TC sensor.

Charge

refrigerant.

Replacd

P.C. board.

Anti-freezing operation

Anti-freezing operation

Does indoor

fan operate?

Are filters clogged?

Is charged amount

of refrigerant normal?

Is outside air

low load?

Indoor P.C. board

is defective.

Is connector

connected properly?

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

Is condenser normal?

Is indoor fan

motor normal?

Connect

connector

properly.

Replace

condenser.

Replace

fan motor.

Is TC sensor

resistance value

(10k

Ω

at 25

°

C) normal?