6-36

EM18-33010A

6. DIAG. TEST OPERATION

(Revision Date: Jan. 14 ‘99)

6.3 PARAMETER SETTING MODE

NOTE:

The following operation cannot be performed unless the sensor type is changed by the issue

command or feed command.

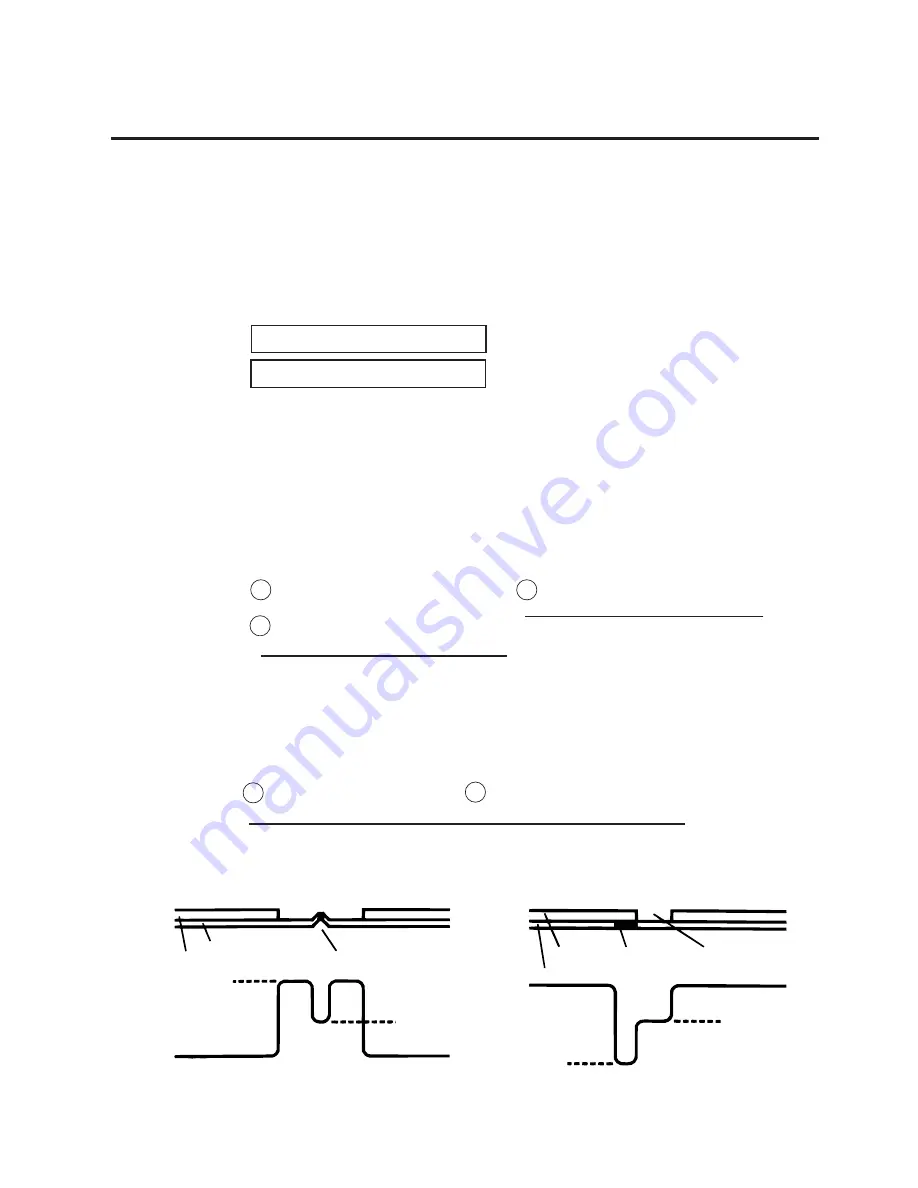

(1) Using the sensor adjustment in Diag. mode, measure the sensor voltage at the following four points.

Label:

Print area Backing paper

Tag paper: Print area Black mark

Example:

(2) Using the following formula, calculate the threshold from the measured voltage:

When using labels (transmissive sensor):

Threshold = (Max. voltage at the backing paper) - (Voltage at the print area) - 0.7V

e.g.)

2.0V = 4.2V - 1.5V - 0.7V

When using perforated labels (transmissive sensor):

Threshold =

(Max. voltage at the backing paper) Min. voltage at the backing paper

Max. voltage at the backing paper

e.g.)

2.2V = 4.4V - (2.8V/2) - (1.6V/2)

When using labels with black marks (reflective sensor):

Threshold = (Min. voltage at the print area) - (Min. voltage at the black mark)

e.g.)

0.4V = (1.5V - 0.7V)/2

[ R E F L E C T I V E ] 2 . 8 V

[ T R A N S M I S S I V E ] 4 . 1 V

2

2

2

-

-

A

A

B

C

D

Backing Parper

Label

Perforation

B

(2.8 V)

A

(4.4 V)

D

(0.7 V)

C

(1.5 V)

Backing Paper

Label

Black Mark

Label gap

Summary of Contents for B-570

Page 3: ......

Page 4: ...PRINTED IN JAPAN EO0 33004 ...

Page 5: ...TEC Thermal Printer B 570 QQ SERIES Owner s Manual ...

Page 33: ......

Page 34: ...PRINTED IN JAPAN EM1 33035 E ...

Page 56: ......

Page 57: ......

Page 58: ...PRINTED IN JAPAN EM10 33006A ...

Page 157: ......

Page 158: ...PRINTED IN JAPAN EM18 33010A ...