1-12

1. OUTLINE OF THE SYSTEM

EM10-33006A

1.5 ELECTRONICS SPECIFICATIONS

5

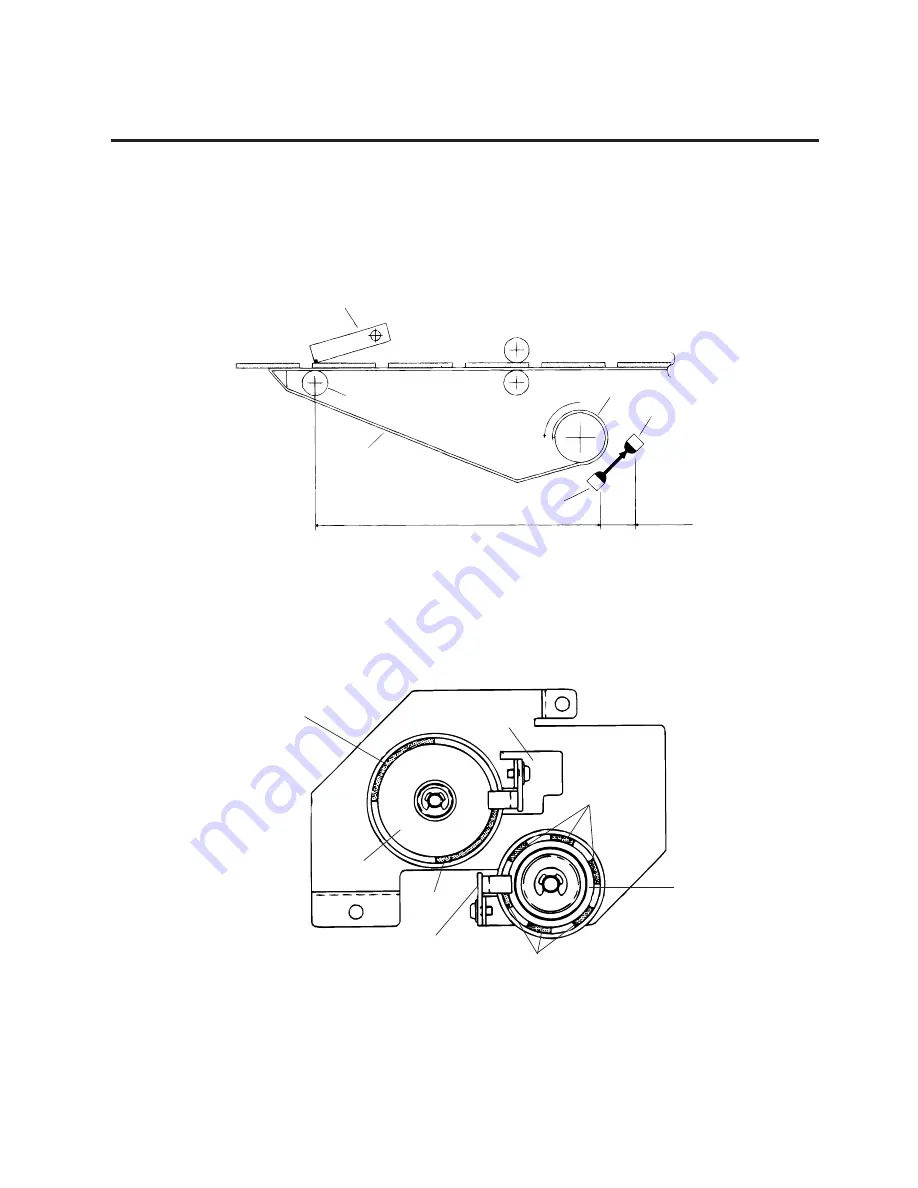

Rewind full sensor (Transmissive sensor)

This sensor detects excessive winding when winding backing paper or label onto the take-

up spool. It is positioned 195.3 mm (Tr side) and 150.9 mm (LED side) from the platen, and

the detection point is 92.5 mm from the main frame. Excessive winding is detected when

backing paper blocks the light from the LED.

6

Slit sensor (Transmissive sensor)

This sensor detects the rotation count of the ribbon shaft and the ribbon motors. The ribbon

motors toque works to take up slack in the ribbon and is dependent on the detected count.

The slit sensor is a photo coupler combining an LED and a transistor.

7

Cutter home position switch (micro switch)

A cam positioned at the end of the cutter motor arm turns the micro switch on/off in

accordance with the cycle of the cutter motion (one rotation). The micro switch status

indicates if the cutter is in the home position.

For details, please refer to the Maintenance Manual section 4.1 Cutter Drive.

Fig. 1-16

Fig. 1-17

Slit

Rewind

Slit Gear

Slit

Slit Sensor (Feed)

Slit

Slit

Feed Slit Gear

Print Head

Platen

Backing Paper

Rewing Full Sensor (LED)

150.9 mm

44.4 mm

Rewind Full

Sensor (Tr)

Take-up Spool

Slit Sensor

(Rewind)

Summary of Contents for B-570

Page 3: ......

Page 4: ...PRINTED IN JAPAN EO0 33004 ...

Page 5: ...TEC Thermal Printer B 570 QQ SERIES Owner s Manual ...

Page 33: ......

Page 34: ...PRINTED IN JAPAN EM1 33035 E ...

Page 56: ......

Page 57: ......

Page 58: ...PRINTED IN JAPAN EM10 33006A ...

Page 157: ......

Page 158: ...PRINTED IN JAPAN EM18 33010A ...