2. PRINTER SETUP

ENGLISH VERSION EO1-33055

2.5 Setting Sensor Positions

E2-10

2.5 Setting Sensor

Positions

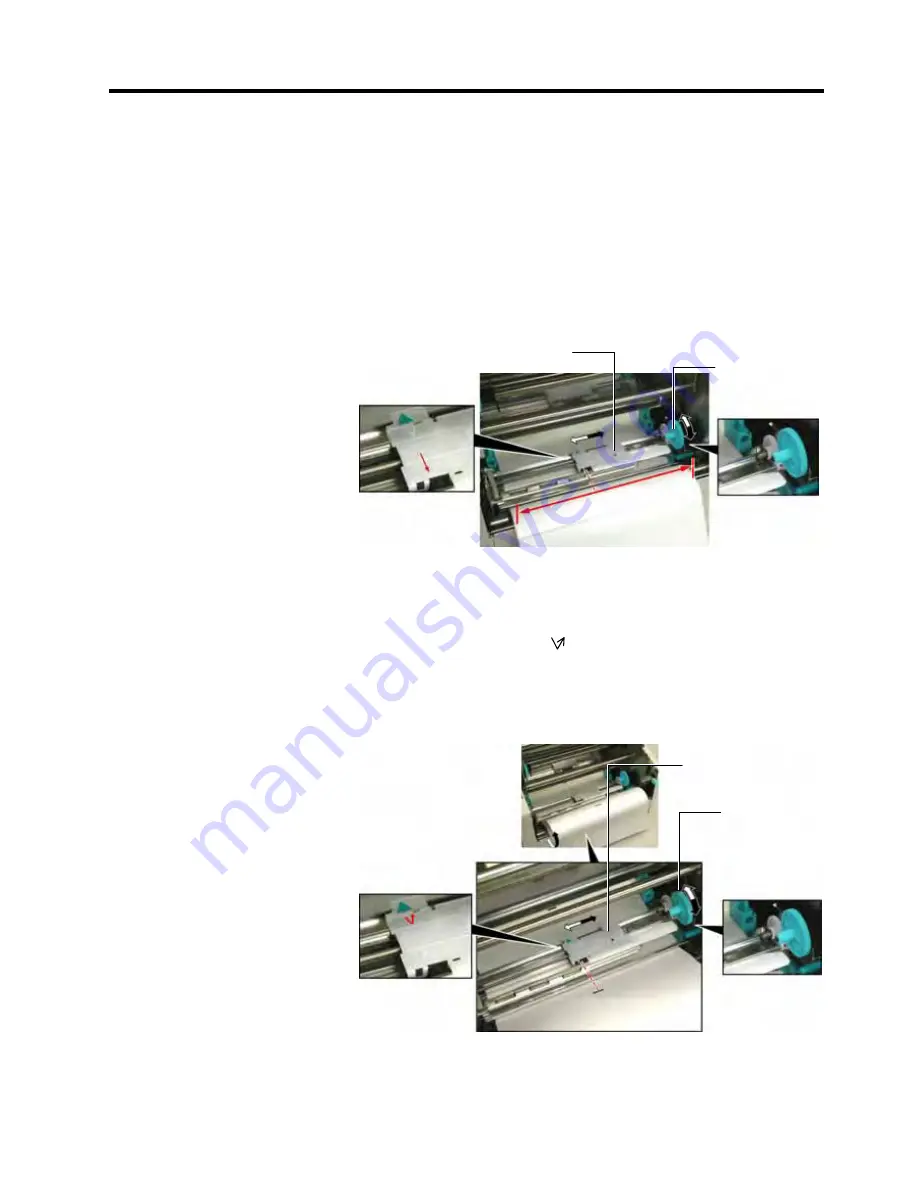

2.5.1 Setting the Feed Gap

Sensor

2.5.2 Setting the Black Mark

Sensor

After loading the media, as outlined in the previous paragraphs, it will

usually be necessary to set the Media Sensors used to detect the print start

position for label or tag printing.

1.

With the Print Head Block raised as described in

section 2.4.3

, pass

the labels under the Upper Sensor Ass’y as shown in the figure below.

2.

Rotate the Green Sensor Adjust Gear to move the Sensor Ass’y to the

left or right to center the arrow (

↑

) over the label.

3.

With the sensor set to the center of the labels, it will be guaranteed to

detect the gap between labels even if the labels are round.

1.

If the Black Mark is printed on the top of the tag media then simply

rotate the Green Sensor Adjust Gear to move the Sensor Ass’y so that

the Black Mark Indicator ( ) is directly in line with the Black Mark

on the top of the paper.

2.

If the Black Mark is printed on the bottom of the tag media then fold

the media back to be able to see the Black Mark and its relationship to

the Sensor Ass’y as shown in the figure below.

Upper Sensor Ass’y

Green Sensor

Adjust Gear

Upper Sensor Ass’y

Green Sensor

Adjust Gear