CHAPTER 5 TPCL MODE (INTERFACE COMMANDS)

B-EP

Series

5-3

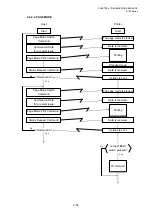

When the back feed restriction setting is on and the label pitch or effective print length conforms to the

condition not to perform a back feed, a label located between the head and cutter at the first printing

subsequent to an issue (one or multiple labels) cannot be printed because no back feed is performed.

This waste can be prevented by switching the stop position in the SYSTEM mode from "CUT" to

"HEAD." However, it is necessary to press the FEED key and move a label to the cut position to take

it out because the label is not stopped at the cut position after printing has been completed.

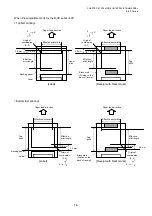

In strip issue mode when the strip issue back feed setting is on and the strip position fine adjustment is

set to – (negative), a back feed is performed to set the next label to the correct print start position.

However, for labels whose label-to-label gap is 5 mm or more, no back feed is performed because

adjustment of the print start position is not required.

<<Common in all versions>>

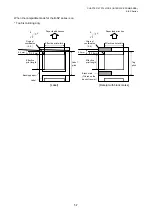

When printing is performed under the following conditions, the print position is misaligned:

In batch issues, use and issue labels shorter than 11.5 mm between the head and sensor, without

setting or by omitting to set a back feed parameter of the print position fine adjust command in LABEL

mode. Then, switch the mode to TPCL mode and issue labels. As a result, the print position of the

second label is misaligned. When labels shorter than the distance between the head and sensor are

used, before LABEL mode is switched to TPCL mode, the gap between the first label and second

label has passed through the sensor before the first label is printed. Therefore, the third and later

labels are printed at the proper position.

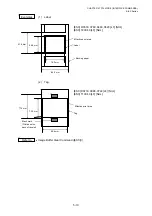

Either of the language types, Kanji, Chinese and Korean, can be implemented. Any font other than

the on-board fonts is selectable.