2. PRINTER SETUP

ENGLISH VERSION EO1-33057

2.11 Position and Print Tone Fine Adjustment

E2-76

2.11 Position and Print

Tone Fine

Adjustment (Cont.)

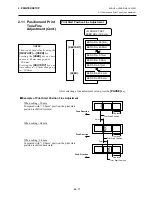

Thermal Transfer Print

After selecting a fine adjustment value or to skip this menu, press the

[PAUSE]

key.

Thermal Direct Print

After selecting a fine adjustment value or to skip this menu, press the

[PAUSE]

key.

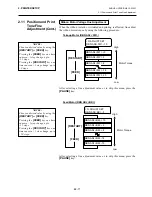

Print Tone Fine Adjustment

NOTES:

Choose a desired value by using the

[RESTART]

or

[FEED]

key.

Pressing the

[FEED]

key one time

causes a –1 tone change, up to

–10 tones.

Pressing the

[RESTART]

key one

time causes a +1 tone change, up to

+10 tones

.

<3>ADJUST SET

TONE ADJ.<T> +3

[RESTART]

[FEED]

TONE ADJ<T>. +10

TONE ADJ<T>. +9

TONE ADJ<T>. +0

TONE ADJ<T>. -9

TONE ADJ<T>. -10

Darker

Lighter

Standard

TONE ADJ<D>. +10

TONE ADJ<D>. +9

TONE ADJ<D>. +0

TONE ADJ<D>. -9

TONE ADJ<D>. -10

[RESTART]

[FEED]

Darker

Lighter

Standard

<3>ADJUST SET

TONE ADJ.<D> -2