– 15 –

Installation Manual

EN-29

EN-30

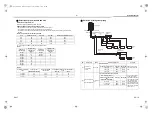

Keep the rule of the following tables about size and length of communication wiring.

Table-1

Control wiring between indoor and outdoor units (L1, L2, L3), Central control wiring (L4)

*1 Total of control wiring length for all refrigerant circuits ( L1 + L2 + L3 + L4 )

Table-2

Control wiring between outdoor units (L5) (Other system)

Table-3

Remote control wiring (L6, L7)

Wiring

2-core, non-polarity

Type

Shield wire

Size / Length *1

AWG16: Up to 3280 ft (1000 m)

AWG14: Up to 6560 ft (2000 m) (*1)

Wiring

2-core, non-polarity

Type

Shield wire

Size / Length

AWG16 to AWG14 / Up to 330 ft (100 m) (L5)

Wiring

2-core

Size

AWG20 to AWG14

Length

• Up to 1640 ft (500 m) (L6 + L7)

• Up 1310 ft (400 m) in case of wireless remote control in group control.

• Up to 660 ft (200 m) total length of control wiring between indoor units (L6)

U3 U4

U1 U2

U1

U3

U2

U4

U1 U2

A B

U3 U4

U1 U2

U1 U2

A B

U1 U2

A B

U1 U2

A B

U1 U2

A B

U1 U2

A B

U3 U4

U1 U2 U5 U6

U1 U2

A B

U1 U2

A B

U1 U2

A B

U3 U4

U1 U2 U5 U6

L1

L5

L6

L6

L7

L7

L4

3

L

2

L

Central

control

This system

Other system

Table-1

Header

unit

Follower

unit

Table-1

Table-2

Table-3

Outdoor unit

Indoor unit

Remote control

Remote control

Remote control

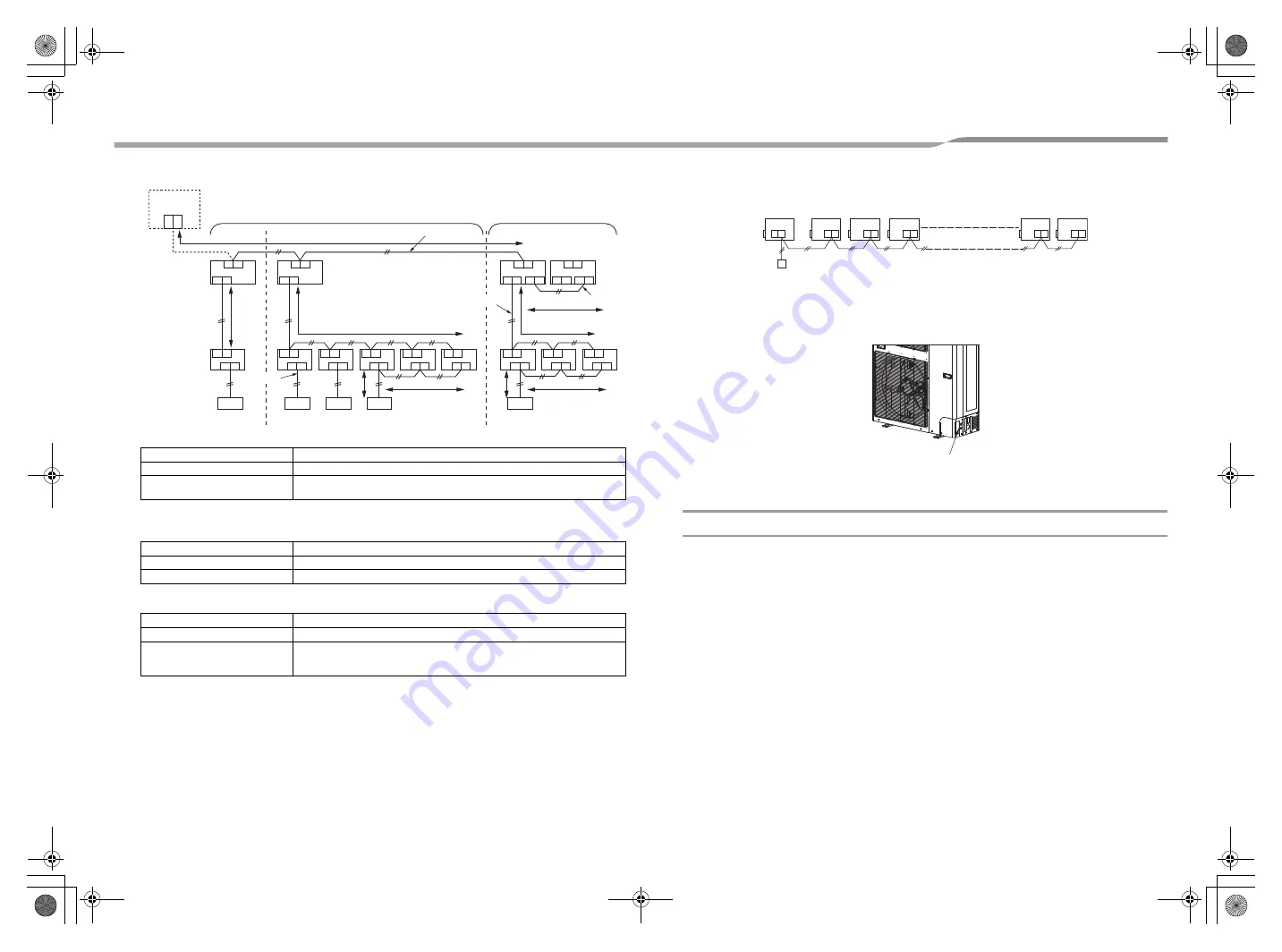

Group control through a remote control

Group control of multiple indoor units (8 units) through a single remote control

Connection of power wires and communication wires

Remove knockouts on the piping / wiring panel or the base and insert the power wires and communication wires

through the holes with the refrigerant piping.

NOTE

Separate the power wire and communication wires.

B

A

B

A

B

A

B

A

B

A

B

A

(A.B)

Indoor unit No.1

No.2

No.3

No.4

No.7

No.8

Remote control

Knockout for the refrigerant piping

+00_EB99809701_00Ta.book Page 15 Tuesday, December 6, 2016 2:07 PM