– 2 –

EN

•

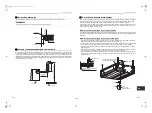

Use the specified wires for wiring connect the terminals. Securely fix them to prevent external forces applied

to the terminals from affecting the terminals.

•

Conform to the regulations of the local electric company when wiring the power supply.

•

For the refrigerant recovery work (collection of refrigerant from the pipe to the compressor), stop the

compressor before disconnecting the refrigerant pipe.

If the refrigerant pipe is disconnected while the compressor is working with the valve open, the compressor sucks air

and the refrigeration cycle is overpressurized, which may cause a burst or injury.

•

Before carrying out the installation, maintenance, repair or removal work, set the circuit breaker to the OFF

position.

Otherwise, electric shocks may result.

•

Do not touch the aluminium fin of the unit. You may injure yourself if you do so. If the fin must be touched

for some reason, first put on protective gloves and safety work clothing, and then proceed.

•

Install the air conditioner securely in a location where the base can sustain the weight adequately. If the

strength is not enough, the unit may fall down resulting in injury.

•

The unit can be accessed from the service panel.

•

Install a circuit breaker that meets the specifications in the installation manual and the stipulations in the

local regulations and laws.

•

Install the circuit breaker where it can be easily accessed by the agent.

•

Under no circumstances the power wire must not be extended. Connection trouble in the places where the

wire is extended may give rise to smoking and/or a fire.

•

Upon completion of the installation work, tell the user where the circuit breaker is located. If the user does

not know where the circuit breaker is, he or she will not be able to turn it off in the event that trouble has

occurred in the air conditioner.

CAUTION

•

This air conditioner adopts the new HFC refrigerant (R410A) which does not destroy ozone layer.

• The characteristics of R410A refrigerant are; easy to absorb water, oxidizing membrane or oil, and its pressure is

approx. 1.6 times higher than that of refrigerant R22. Accompanied with the new refrigerant, refrigerating oil has also

been changed. Therefore, during installation work, be sure that water, dust, former refrigerant, or refrigerating oil does

not enter the refrigerating cycle.

• To prevent charging an incorrect refrigerant and refrigerating oil, the sizes of connecting sections of charging port of

the main unit and installation tools are changed from those for the conventional refrigerant.

• Accordingly the exclusive tools are required for the new refrigerant (R410A).

• For connecting pipes, use new and clean piping designed for R410A, and please care so that water or dust does not

enter.

•

Tighten the flare nut with a torque wrench in the specified manner.

Excessive tightening of the flare nut may cause a crack in the flare nut after a long period, which may result in

refrigerant leakage.

•

Wear heavy gloves during the installation work to avoid injury.

2

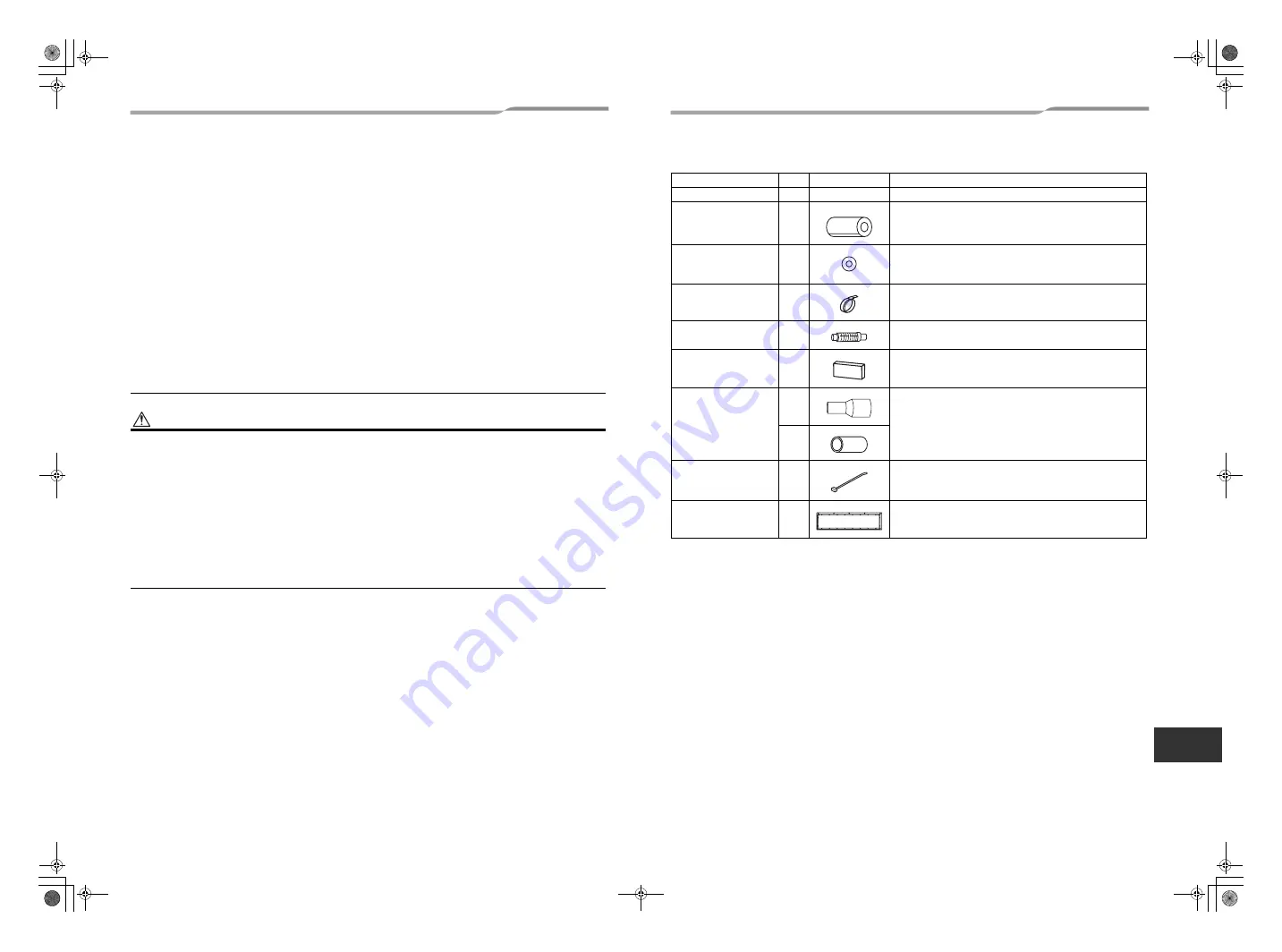

Accessory parts

Part name

Q’ty

Shape

Usage

Installation Manual

1

This manual

(Hand over to customers)

Heat insulating pipe

2

For heat insulation of pipe connecting section

Washer

8

For hanging-up unit

Hose band

1

For connecting drain pipe

Flexible hose

1

For adjustment of drain pipe centering

Heat insulator

1

For insulating drain connecting section

Drain socket

1

For connect drain pipe

1

Banding band

2

For fixing of pipe connecting heat insulator

Air intake port flange

1

For connecting a duct when air intake is from the back

3-EN

4-EN

+00EH99885401.book Page 2 Friday, March 2, 2012 11:01 AM