– 8 –

EN

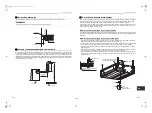

Connecting drain pipe

Insert flexible drain hose into upper drain pipe of main unit as far as it will go. Fix it with hose band.

REQUIREMENT

Mount the flexible drain hose using the hose band without using adhesive.

Drain up (condensate pumped up from unit)

When gravity drainage cannot be provided directly from the indoor unit condensate exit the piping can be arranged

for upward condensate discharge. The vertical leg of the drain line must be a maximum of 15.8”(400 mm) or less

from the indoor condensate exit and the total vertical height of the leg must be a maximum of 33.5”(850 mm) or

less before the drain enters a gravity flow line. These dimensions are specified by the indoor unit condensate pump

limitations. As specified for the gravity flow installation all materials and suspension methods must comply with

applicable codes and regulations.

Flexible

drain hose

Hose band

0.

4

” to

0

.5

”

(

10 t

o

12

mm

)

0.6

” (

15 mm) or less

Indoor unit

Ris

ing

u

p

2

3.

1”(

58

7 mm

)

or

le

ss

Underside of ceiling

Indoor unit

15.8”(

400 mm)

or less

R

isin

g up

33

.5

”(

85

0 m

m

)

o

r les

s

Check the condensate drain system

When all piping and wiring is completed the condensate drain system (including the pump) should be checked for

correct operation and leaks. If there are any abnormal sounds, leaks, or if the condensate water does not flow

normally, the problem should be diagnosed and corrected before the system is certified for operation.

In the test run, check that water drain is properly performed and water does not leak from the connecting part of

the pipes. When doing this, also check that no abnormal sounds are heard from the drain pump motor. Check

draining also when installed in heating period.

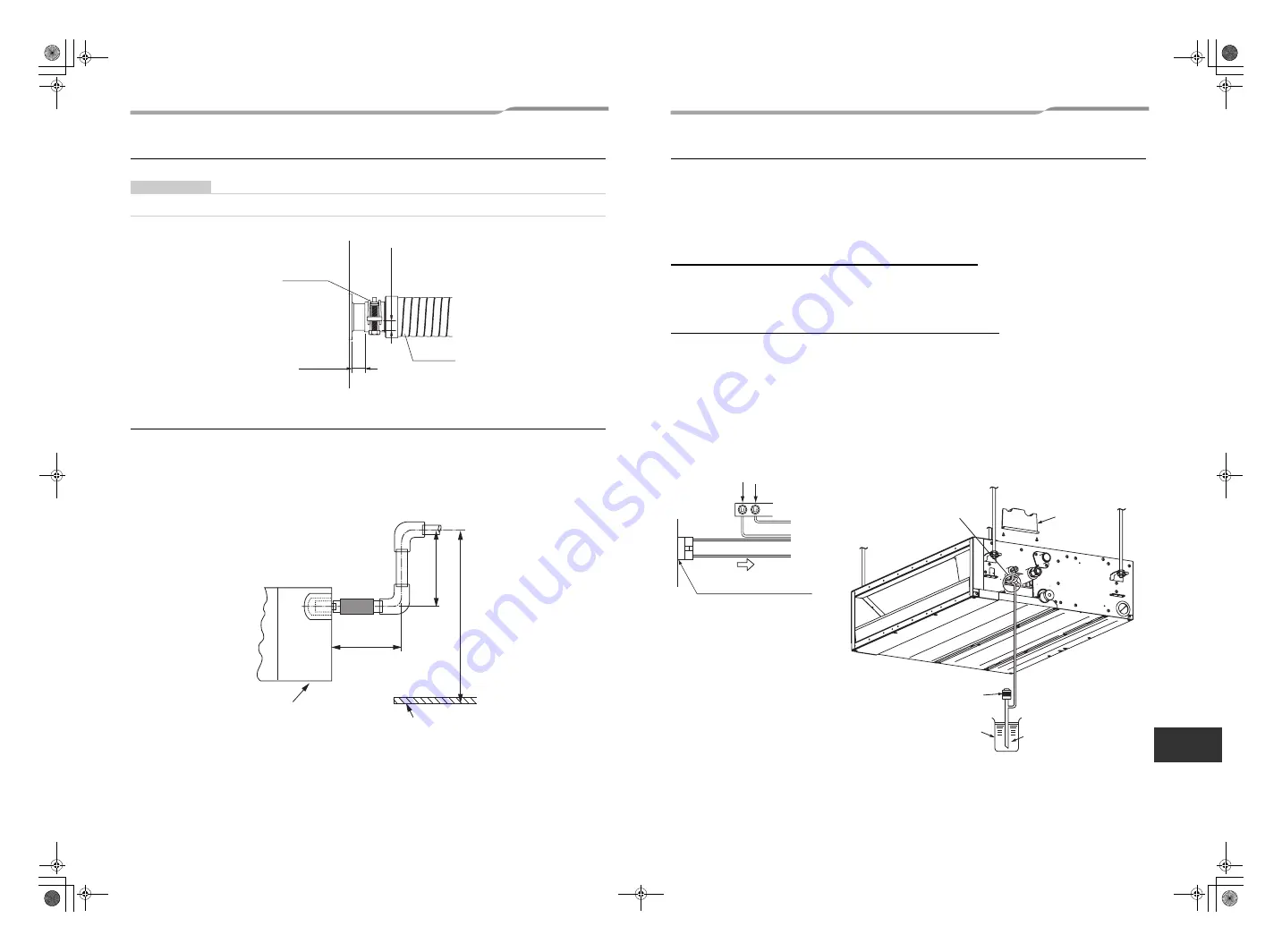

When the electrical and wiring work has been completed

Pour some water by following the method shown in the following figure. Then, while performing a cooling operation,

check that the water drains from the drain pipe connecting port (transparent) and that no water is leaking from the

drain pipe.

When the electrical and wiring work has not been completed

• Disconnect the float switch connector (3P: Red) from the connector (CN34: Red) on the printed circuit board

inside the electrical control box. (Before doing this, the power must be turned off.)

• Connect a 208 / 230 V supply voltage to (L1) and (L2) on the power supply terminal block. (Do not apply a 208

/ 230 V voltage to (A), (B) of the terminal block. Otherwise, the printed circuit board may be damaged.)

• Pour the water by following the method shown in the following figure. (Amount of water poured: 0.4 to 0.5 gal

(1500 to 2000 cc))

• When the power is turned on, the drain pump automatically starts running. Check whether the water is draining

from the drain pipe connecting port, and check that no water is leaking from the drain pipe.

• After checking that the water drains and there are no water leaks, turn off the power, connect the float switch

connector to its original location (CN34) on the printed circuit board, and return the electrical control box to its

original position.

208 / 230-1-60

Pull out connector CN34 (Red)

from P.C. board.

White

Red

Black

Black

Pump

Insert the edge of hose into the

drain pan and bend it downward.

Water

(0.4 to 0.5 gal

(1500 to 2000 cc))

Vessel

Cover plate

15-EN

16-EN

+00EH99885401.book Page 8 Friday, March 2, 2012 11:01 AM