035-000051-001

Page 11 of 60

MMD IOM 1.2 11-10-2020

Ceiling Suspension: Mount the unit in ceiling-

suspended horizontal orientation per suspen-

sion details (Figure 4a). Unit is NOT intended

to be wall mounted. Consult a qualified struc-

tural engineer for special mounting considera-

tions.

Install the unit so that it pitches slightly –(1/8

inch) – toward the condensate drain connec-

tion.

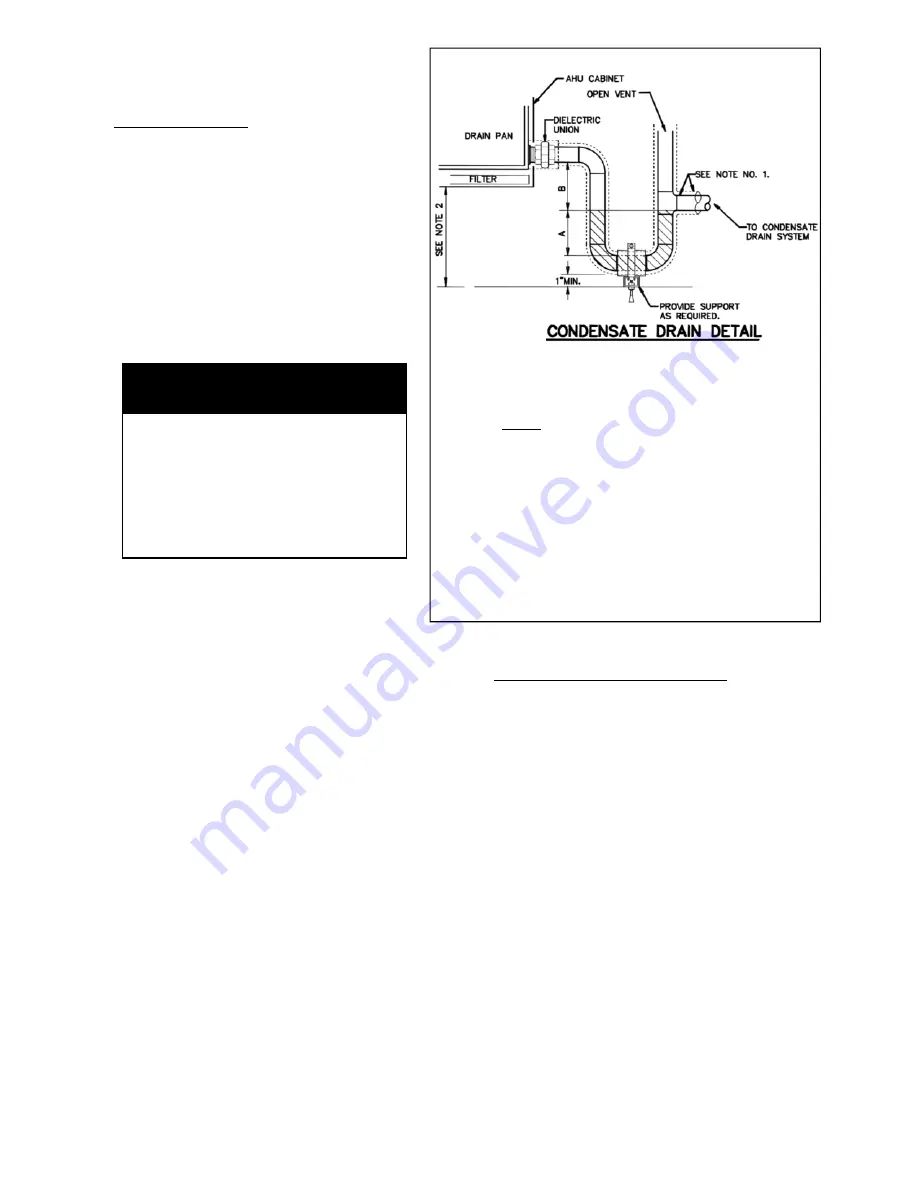

Condensate Drain

Install a trapped condensate drain line at unit

drain connection. All MMD units have 3/4 in.

FPT condensate main and auxiliary drain

connections.

Provide adequate trap clearance (trap depth)

beneath the unit as indicated in Fig. 3. Pro-

vide freeze-up protection as required to in-

sure reliable condensate drainage. Freeze protec-

tion measures are customer-supplied and in-

stalled.

Pipe to condensate drain using PVC or copper or

other suitable material. Pitch drain piping down-

ward at a minimum slope of 1/8 inch per foot.

Pipe auxiliary drain to “tell tale” drain location or

floor drain to clearly indicate when condensate

drain service is required. Alternately, use a field-

provided condensate overflow detection device in

the auxiliary drain connection to provide alarm or

other controls action when the drain pan fills to the

level of the auxiliary drain.

Placing Unit In Ductwork

1. Utilize flexible transitions on supply and return

connections to reduce noise and vibration trans-

mission to the structure.

2. When the connecting return air duct is smaller

than the coil inlet opening, construct the transi-

tion piece so that the vertical and horizontal di-

mensions of the transition piece do not increase

more then one inch for every seven inches of

length of the transition piece.

3. Provide at least three feet of straight duct work

preceding the unit inlet.

INSTALLATION

WARNING

INSURE THAT THE UNIT IS ADE-

QUATELY

SUPPORTED

FROM

STRUCTURE TO PREVENT DAMAGE

OR INJURY CAUSED BY FALLING

EQUIPMENT! If uncertain about how

to connect to the structure, consult a

qualified structural engineer.

Fig. 3 — Condensate Drain

Duct Insulation and Vapor Proofing:

Properly select and install duct insulation as

required by the application.

All externally insulated duct work must have an

adequate vapor seal for summer operation. This

is particularly important where the duct is ex-

posed to highly humid conditions in such places

as attics, vented crawl spaces, unconditioned

basements, and utility rooms. The vapor seal

prevents condensation of moisture in the insu-

lating material and subsequent loss of its insu-

lating value.

NOT TO SCALE

MAINTAIN THESE DIMENSIONS FOR ADEQUATE TRAP

SEAL:

A = 3.5” MINIMUM

B = 2.0” MINIMUM

NOTES:

1. CONDENSATE DRAIN PIPING RECOMMENDATIONS:

A. MINIMUM 3/4” Φ PIPE SIZE

B. COPPER OR PVC PIPE MATERIAL

C. USE DIELECTRIC UNION FOR DISSIMILAR METALS.

D. INSULATE PER PROJECT SPECIFICATIONS.

2. PAD OR PLENUM HEIGHT AS REQUIRED TO INSTALL

TRAP AND CONDENSATE DRAIN PIPING.

3. AVOID BLOCKING FILTER SERVICE ACCESS WHEN

INSTALLING CONDENSATE DRAIN PIPING.

Summary of Contents for Carrier MMD-AP0180VHG2UL

Page 2: ...035 000051 001 Page 2 of 60 MMD IOM 1 2 11 10 2020 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 4: ...035 000051 001 Page 4 of 60 MMD IOM 1 2 11 10 2020 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 6: ...035 000051 001 Page 6 of 60 MMD IOM 1 2 11 10 2020 PRODUCT NOMENCLATURE ...

Page 27: ...035 000051 001 Page 27 of 60 MMD IOM 1 2 11 10 2020 AIRFLOW PERFORMANCE ...

Page 31: ...035 000051 001 Page 31 of 60 MMD IOM 1 2 11 10 2020 SPECIAL FACTORY OPTIONS ...

Page 42: ...035 000051 001 Page 42 of 60 MMD IOM 1 2 11 10 2020 SPECIAL INSTRUCTIONS CONTROLS ...

Page 43: ...035 000051 001 Page 43 of 60 MMD IOM 1 2 11 10 2020 SPECIAL INSTRUCTIONS CONTROLS ...

Page 46: ...035 000051 001 Page 46 of 60 MMD IOM 1 2 11 10 2020 REPLACEMENT PARTS ...

Page 47: ...035 000051 001 Page 47 of 60 MMD IOM 1 2 11 10 2020 REPLACEMENT PARTS ...

Page 48: ...035 000051 001 Page 48 of 60 MMD IOM 1 2 11 10 2020 REPLACEMENT PARTS ...

Page 49: ...035 000051 001 Page 49 of 60 MMD IOM 1 2 11 10 2020 REPLACEMENT PARTS ...

Page 50: ...035 000051 001 Page 50 of 60 MMD IOM 1 2 11 10 2020 REPLACEMENT PARTS ...

Page 51: ...035 000051 001 Page 51 of 60 MMD IOM 1 2 11 10 2020 REPLACEMENT PARTS ...

Page 52: ...035 000051 001 Page 52 of 60 MMD IOM 1 2 11 10 2020 REPLACEMENT PARTS ...

Page 53: ...035 000051 001 Page 53 of 60 MMD IOM 1 2 11 10 2020 REPLACEMENT PARTS ...

Page 54: ...035 000051 001 Page 54 of 60 MMD IOM 1 2 11 10 2020 REPLACEMENT PARTS ...

Page 55: ...035 000051 001 Page 55 of 60 MMD IOM 1 2 11 10 2020 REPLACEMENT PARTS 19 ...

Page 56: ...035 000051 001 Page 56 of 60 MMD IOM 1 2 11 10 2020 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 58: ...035 000051 001 Page 58 of 60 MMD IOM 1 2 11 10 2020 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 59: ...035 000051 001 Page 59 of 60 MMD IOM 1 2 11 10 2020 THIS PAGE INTENTIONALLY LEFT BLANK ...