�

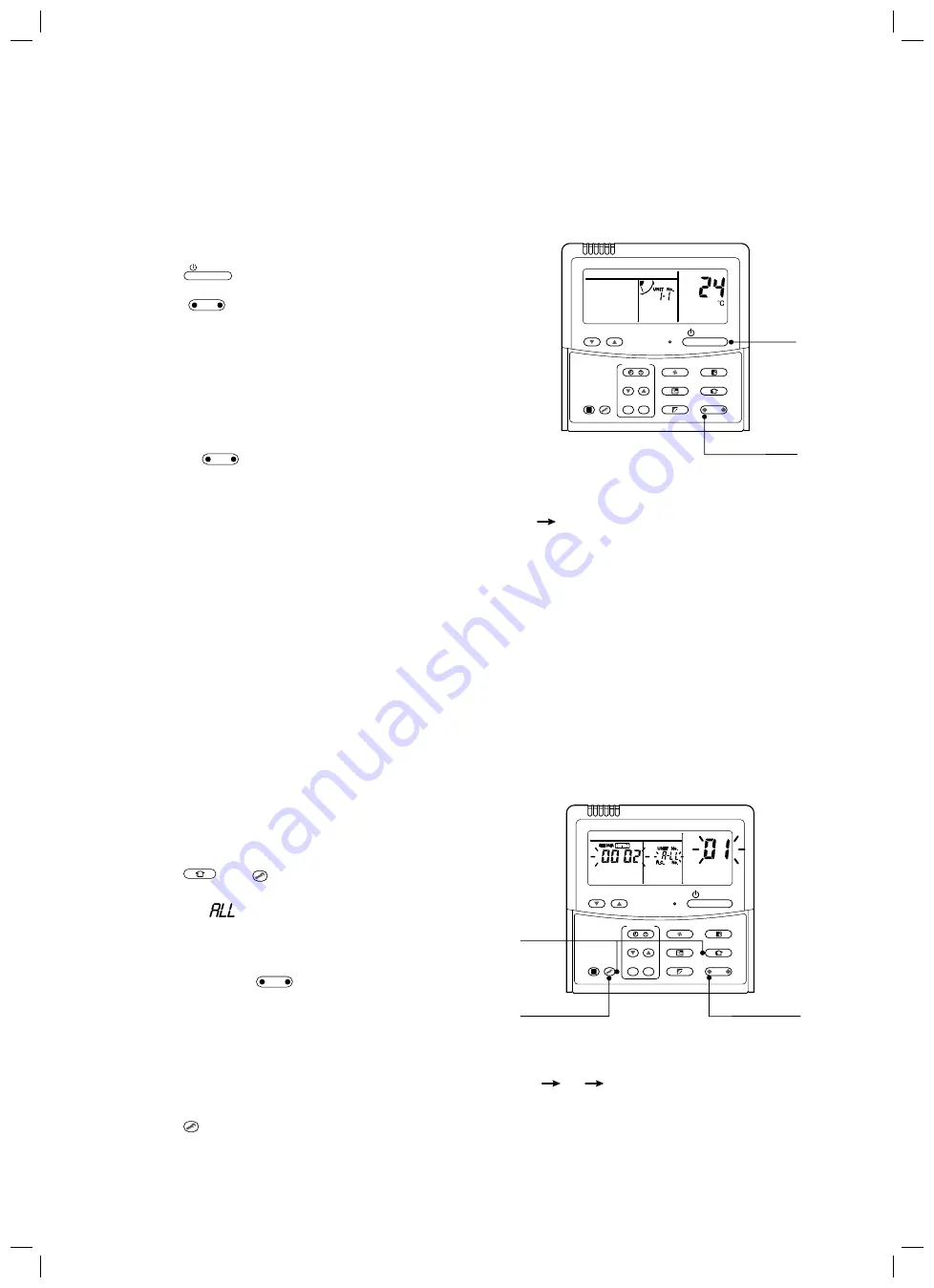

Confirmation of indoor unit No. position

1. To know the indoor unit addresses though position of the indoor unit is recognized

• In case of individual operation (Wired remote controller : indoor unit = 1 : 1)

(Follow to the procedure during operation)

1 2

END

Operation

<Operation procedure>

2

1

SET

TIME

TIMER SET

TEST

FILTER

RESET

TEMP.

CL

FAN

SAVE

SWING/FIX

VENT

MODE

ON / OFF

UNIT LOUVER

1 2 3

END

<Operation procedure>

3

1

2

SET

TIME

TIMER SET

TEST

FILTER

RESET

TEMP.

CL

FAN

SAVE

SWING/FIX

VENT

MODE

ON / OFF

UNIT LOUVER

<Procedure>

1

Push

ON / OFF

button if the unit stops.

2

Push

UNIT LOUVER

(left side button) button.

Unit No. 1-1 is displayed on LCD.

(It disappears after several seconds.)

The displayed unit No. indicate line address and

indoor unit address.

(When other indoor units are connected to the

identical remote controller (Group control unit),

other unit numbers are also displayed every

pushing

UNIT LOUVER

(left side button) button.

2. To know the position of indoor unit by address

• To confirm the unit No. in the group control

(Follow to the procedure during operation) (in this procedure, the indoor units in group control stop.)

<Procedure>

The indoor unit numbers in the group control are

successively displayed, and fan, louver, and drain pump

of the corresponding indoor unit are turned on.

(Follow to the procedure during operation)

1

Push

VENT

and

TEST

buttons simultaneously for

4 seconds or more.

• Unit No.

is displayed.

• Fans and louvers of all the indoor units in the

group control operate.

2

Every pushing

UNIT LOUVER

(left side button) button,

• The unit No. displayed at the first time indicates

the header unit address.

• Fan and louver of the selected indoor unit only

operate.

3

Push

TEST

button to finish the procedure.

All the indoor units in the group control stop.

successively displayed.

the unit numbers in the group control are

�

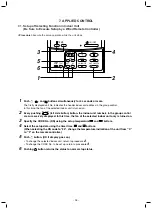

Address setup (Manual setting from remote controller)

In case that addresses of the indoor units will be

determined prior to piping work after cabling work

• Set an indoor unit per a remote controller.

• Turn on power supply.

1

Push

SET

+

CL

+

TEST

buttons simultaneously

for 4 seconds or more.

2

(Line address)

Using the temperature setup

/

buttons, set

��

to the CODE No.

3

Using timer time

/

buttons,

set the line address.

4

Push

SET

button. (OK when display goes on.)

5

(Indoor unit address)

Using the temperature setup

/

buttons, set

��

to the CODE No.

6

Using timer time

/

buttons,

set 1 to the line address.

7

Push

SET

button. (OK when display goes on.)

8

(Group address)

Using the temperature setup

/

buttons, set

��

to the CODE No.

9

Using timer time

/

buttons,

set

����

to Individual,

����

to

Master unit and

����

to sub unit.

10

Push

SET

button.

(OK when display goes on.)

11

Push

TEST

button.

Setup completes.

(The status returns to the usual stop status.)

(Example of 2-lines cabling)

(Real line: Cabling, Broken line: Refrigerant pipe)

For the above example, perform setting by connecting singly the

wired remote controller without remote controller inter-unit cable.

Group address

Individual

: 0000

In case of group control

Outdoor

Outdoor

Indoor

Indoor

Indoor

Indoor

Indoor

unit

Line address 1

Indoor unit address 1

Group address 1

1

2

2

1

3

2

2

1

2

2

2

2

<Operation procedure>

1 2 3 4 5 6

1

3, 6, 9

END

11

2, 5, 8

4, 7, 10

SET

TIME

TIMER SET

TEST

FILTER

RESET

TEMP.

CL

FAN

SAVE

SWING/FIX

VENT

MODE

ON / OFF

UNIT LOUVER

7 8 9 10 11

END

Note 1)

When setting the line address from the remote controller, do not use Address 29 and 30.

As they are addresses which cannot be set to the outdoor unit, if they are set, the check code [E04] (Indoor/Outdoor

communication circuit error) is issued.

Note 2)

When an address was manually set from the remote controller and the central control over the refrigerant lines is

carried out, perform the following setting for the Master unit of each line.

• Set the line address for every line using SW13 and 14 on the interface P.C. board of the center unit in each line.

• Except the least line address No., turn off SW30-2 on the interface P.C. board of the Master units in the lines

connected to the identical central control.

(Draw the terminal resistances of indoor/outdoor and central control line wirings together.)

• For each refrigerant line, connect the relay connector between Master unit [U1U2] and [U3U4] terminals.

• After then set the central control address.

(For setting of the central control address, refer to the Installation manual for the central control equipment.)

Follower

Header unit

Header unit : 0001

Follower unit : 0002

- 43 -

Summary of Contents for Carrier MMU-AP0074HPUL

Page 15: ...2 WIRING DIAGRAM 15 ...