4

2

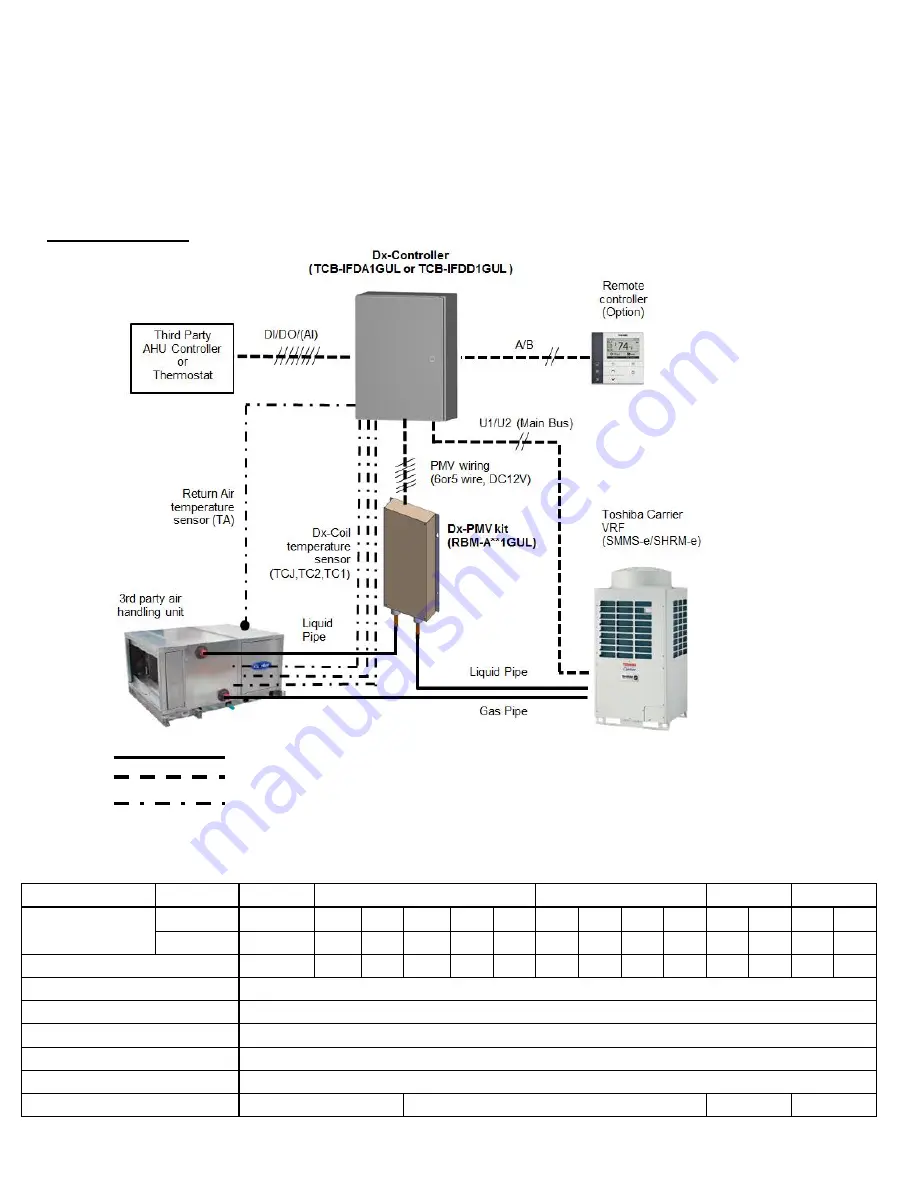

OVERVIEW: Dx-Interface / Dx-PMV kit

The Dx-Interface system enables third party coil connection to Toshiba Carrier VRF outdoor units.

The Dx-PMV kit is installed as the external expansion valve between VRF refrigerant piping and 3

rd

party Dx-coil.

VRF systems require an appropriately sized Dx-PMV kit which must be brazed to the Dx-Coil used in conjunction with the Dx-

Controller (RA control type or 0-10V type).

Installation Scene

Refrigerant piping (Maximum piping length from Dx-PMV kit to 3

rd

party coil : 16ft)

Control wiring (Field installed)

Temperature sensor wiring

■

SPECIFICATION

(*1) Install in the place avoiding direct sunlight and rain

Model name

RBM-A

0121UL

0301GUL

0601GUL

0961GUL

1921GUL

Capacity

Code

012

015

018

021

024 030 036 042 048 060 072 096 168 192

Ton

1

1.25

1.5

1.75

2

2.5

3

3.5

4

5

6

8

14

16

Maximum capacity kBtu/h

12

15.4

18

21

24

30

36

42

48

60

72

96

168 192

Power supply requirements

Powered by Dx-Controller [12VDC]

For use with

Dx-Controller (TCB-IFDA1GUL / TCB-IFDD1GUL)

Ambient operating temp. range (*1)

22 to 115F

Ambient operating humidity range(*1)

10 to 90% (Non-Condensing)

Communication cable

AWG20 or 22 X 6 wires (5 wires in case of RBM-1681GUL)

Piping connections in.

1/4“ X 1/4”

3/8” X 3/8”

1/2”X1/2”

5/8”X5/8”