December 2000 © TOSHIBA TEC

1 - 55

1600/2000/2500 ADJUSTMENT ITEMS

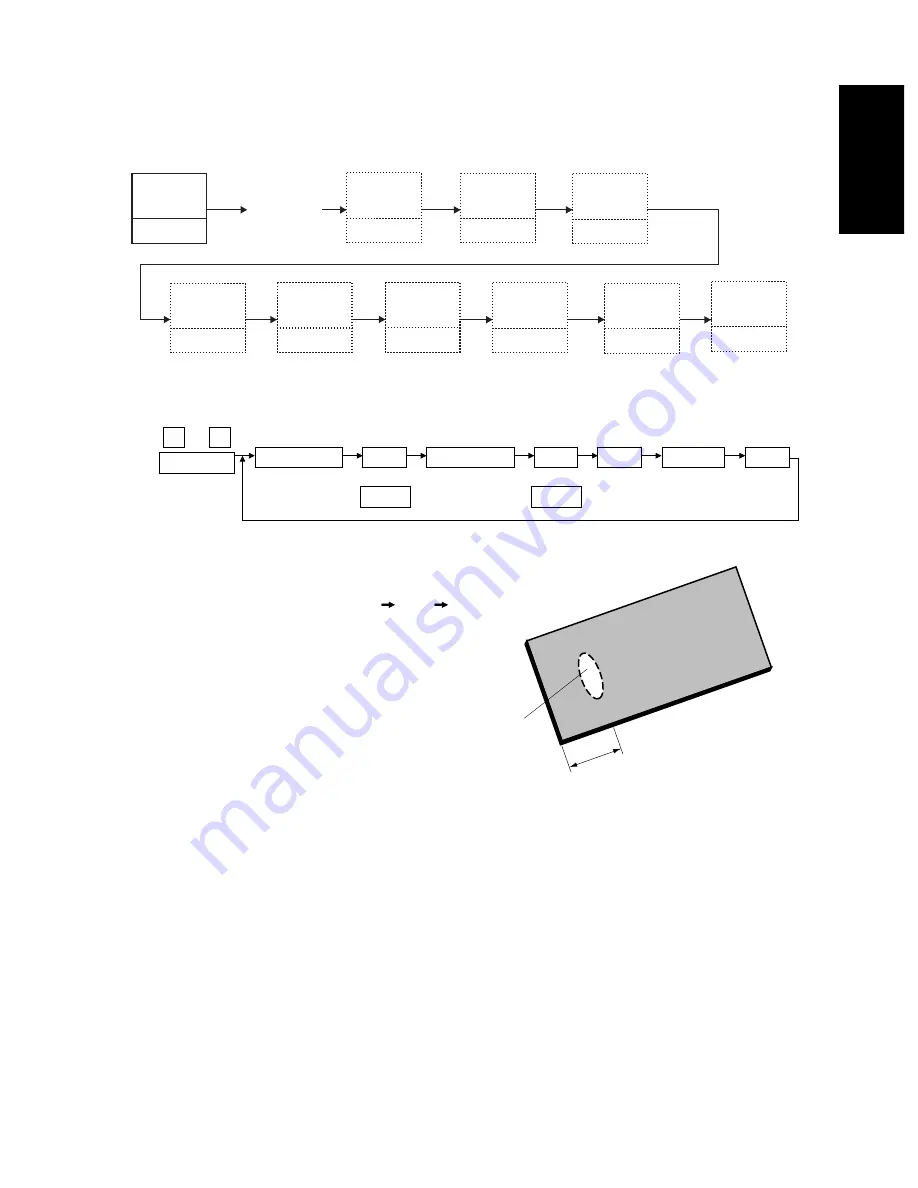

1.4.1 Adjustment of paper aligning value

<Procedure> (Use code 450 - 453, 455, 456, 457, 458, 463, 465 in the "05" mode.)

(2) Check the copy for image void and if there is

any, reduce the new value to "31"

"30"

"29"... until no void occurs. Check for paper

misfeeding.

When the aligning value is increased, noise

caused by the paper scraping against the Mylar

may possibly be increased.

(3) For the LCF, ADU and bypass, the same pro-

cedure can be used.

(1)

Notes:

1. When frequent paper jams occur near the aligning roller caused by using special thin paper

other than that specified, the aligning value can be changed (reduced) as a measure. However,

when the aligning value is reduced excessively, this may possibly cause the registration to be

shifted. Therefore, make sure that no registration shifting occurs while adjusting the value.

2. Long size adjustment is used as the base when there are both long and short adjustments.

3. Adjusts the code only for option attached.

Power ON

0

5

Digital Keys

(Code)

SET

Digital Keys

(Set the value)

SET

INT

START

(Test copy)

INT

01-04-02

50 - 1

00 m

m

Void

or

START

or

START

If necessary

LCF

457

Cassette 1

(Short)

451

Cassette 1

(Long)

450

Cassette 2

(Long)

452

Cassette 2

(Short)

453

ADU

455

PFP

(Short)

456

Bypass

(Short)

458

PFP

(Long)

463

Bypass

(Long)

465

* As a tentative countermeasure, the service life of the feed roller can be extended by increasing the

aligning amount.

02/01