e-STUDIO160/200/250 SCANNER

7 - 28

December 2002 TOSHIBA TEC

Fig. 7-8-31

Fig. 7-8-32

Wire

Wire roller

Wire

Wire

Wire

Timing belt 157

Scanner drive gear

Scanner

drive shaft

Bearing

E-ring

Bearing

E-ring

Wire

064-1

Screw

063-1

16. Remove spring plate securing mirror 3 and re-

move mirror 3.

Notes:

1. Clean the surface of mirror 3 if dirty.

2. For mounting Carriage 2, refer to the Ser-

vice Handbook. (See Chapter 1.8)

[CAUTION]

Never turn the angle adjusting screw of mirror.

Fig. 7-8-30

Spring plate

Spring plate

Mirror 3

Screw

Spring plate

060-3

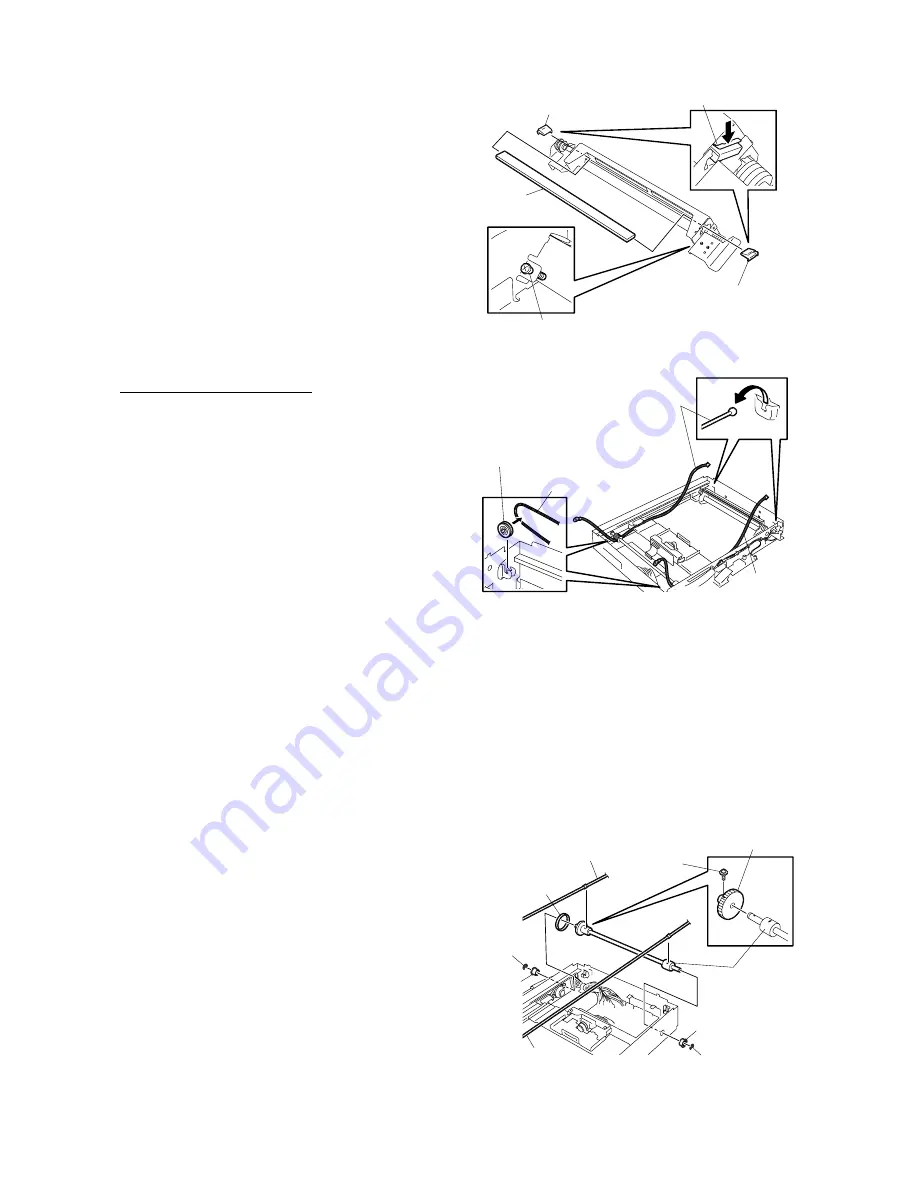

[I] Scanner drive shaft/wire

1. 1.

If an Original Cover (KA-1600PC), ADF

(MR-2012), or the RADF (MR-3011) is attached

to the copier, detach it.

2. If a STP (KK-1600) is attached to the copier,

detach it.

3. Detach the manual pocket.

4. If a Finisher (MJ-1011) is attached to the copier,

detach the finisher plate.

5. Remove scanner assembly.

(See Fig. 7-8-1 to 7-8-6)

6. Remove scanner motor assembly.

(See Fig. 7-8-9 and 7-8-11)

7. Release the lamp cable.

(See Fig. 7-8-19 to 7-8-22)

8. Remove the blind plate.

(See Fig. 7-8-16 and 7-8-17)

9. Remove carriage 1. (See Fig. 7-8-24)

10. Detach wire from carriage 2. (See Fig. 7-8-27)

11. Remove wire roller from scanner frame and

release wire.

12. Detach 2 E-rings and 2 bearings, remove

scanner drive shaft assembly, and remove

timing belt 157.

13. Detach wire from scanner drive shaft assembly.

14. Remove the screw and remove scanner drive

gear.

Note:

For winding the wire, refer to the Service

Handbook. (See Chapter 1.8)

Summary of Contents for e-studio 160

Page 2: ... 2002 TOSHIBA TEC CORPORATION All rights reserved ...

Page 223: ...e STUDIO160 200 250 PCB BOARD 16 2 December 2002 TOSHIBA TEC 16 2 PWA F RLY 16 02 01 ...

Page 224: ...December 2002 TOSHIBA TEC 16 3 e STUDIO160 200 250 PC BOARD 16 3 PWA F PIF 16 03 01 ...

Page 226: ...December 2002 TOSHIBA TEC 16 5 e STUDIO160 200 250 PC BOARD 16 6 PWA F SLG 16 06 01 ...

Page 228: ...17 WIRE HARNESS CONNECTION DIAGRAMS 17 1 ...

Page 255: ...1 1 KANDA NISHIKI CHO CHIYODA KU TOKYO 101 8842 JAPAN ...