e-STUDIO160/200/250 COPYING PROCESS

3 - 2

December 2002 TOSHIBA TEC

3.2 Details of Copying Process

(1) Photosensitive Drum

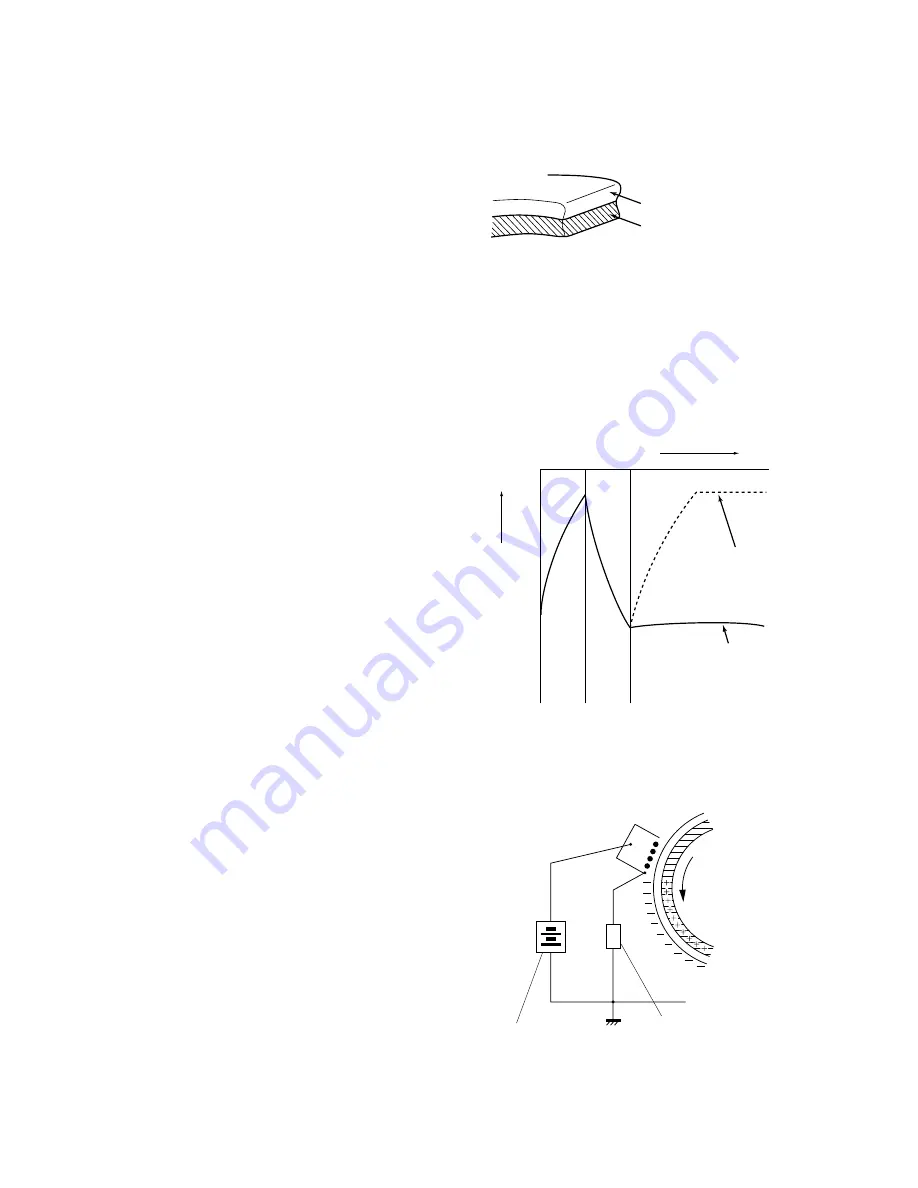

The photosensitive drum has two layers, an

outer and an inner layer. The outer layer is a

photoconductive layer that uses an organic

photoconductive carrier (OPC), and the inner

layer is an aluminum, conductive cylindrical

drum.

The resistance held by the drum material

changes (increases, decreases) according to

the strength of the light incident to the photo-

conductive carrier.

(Example)

• When incident light is strong, the resistance

decreases (photosensitive drum becomes a

carrier).

• When incident light is weak, the resistance

increases (photosensitive drum becomes an

insulator).

[Formation of Electrostatic Latent Image]

The minus potential on the drum surface cor-

responding to black areas of the original are

removed by the charging, scanning, printing

and discharging processes (described later),

and the minus potential remains on areas cor-

responding to white areas of the original.

The image on the drum resulting from this mi-

nus potential is called a “latent image” as it can-

not be seen directly by the human eye.

(2) Charging

"Charging" is the process of uniformly apply-

ing a charge to the surface of the photosensi-

tive drum.

The minus corona discharge of the charger wire

is controlled by the grid to charge the drum sur-

face to a uniform minus potential.

The drum surface potential is determined by

the potential of the grid, and the grid is deter-

mined by the grid control circuit inside the trans-

former.

Fig. 3-2-2

Electric potential of the photosensitive drum

Base

Photoconductive layer

Fig. 3-2-1 Structure of the photosensitive drum

03002

03003

0

– 500

– 1000

Time (t)

Black area of original

White area of original

Dis-

charge

process

Charg-

ing

process

Surface potential (V)

03004

Transformer

Main charger

Rotation of drum

Grid control circuit

Fig. 3-2-3

Summary of Contents for e-studio 160

Page 2: ... 2002 TOSHIBA TEC CORPORATION All rights reserved ...

Page 223: ...e STUDIO160 200 250 PCB BOARD 16 2 December 2002 TOSHIBA TEC 16 2 PWA F RLY 16 02 01 ...

Page 224: ...December 2002 TOSHIBA TEC 16 3 e STUDIO160 200 250 PC BOARD 16 3 PWA F PIF 16 03 01 ...

Page 226: ...December 2002 TOSHIBA TEC 16 5 e STUDIO160 200 250 PC BOARD 16 6 PWA F SLG 16 06 01 ...

Page 228: ...17 WIRE HARNESS CONNECTION DIAGRAMS 17 1 ...

Page 255: ...1 1 KANDA NISHIKI CHO CHIYODA KU TOKYO 101 8842 JAPAN ...