11-13

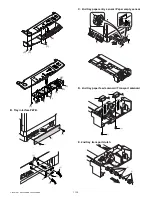

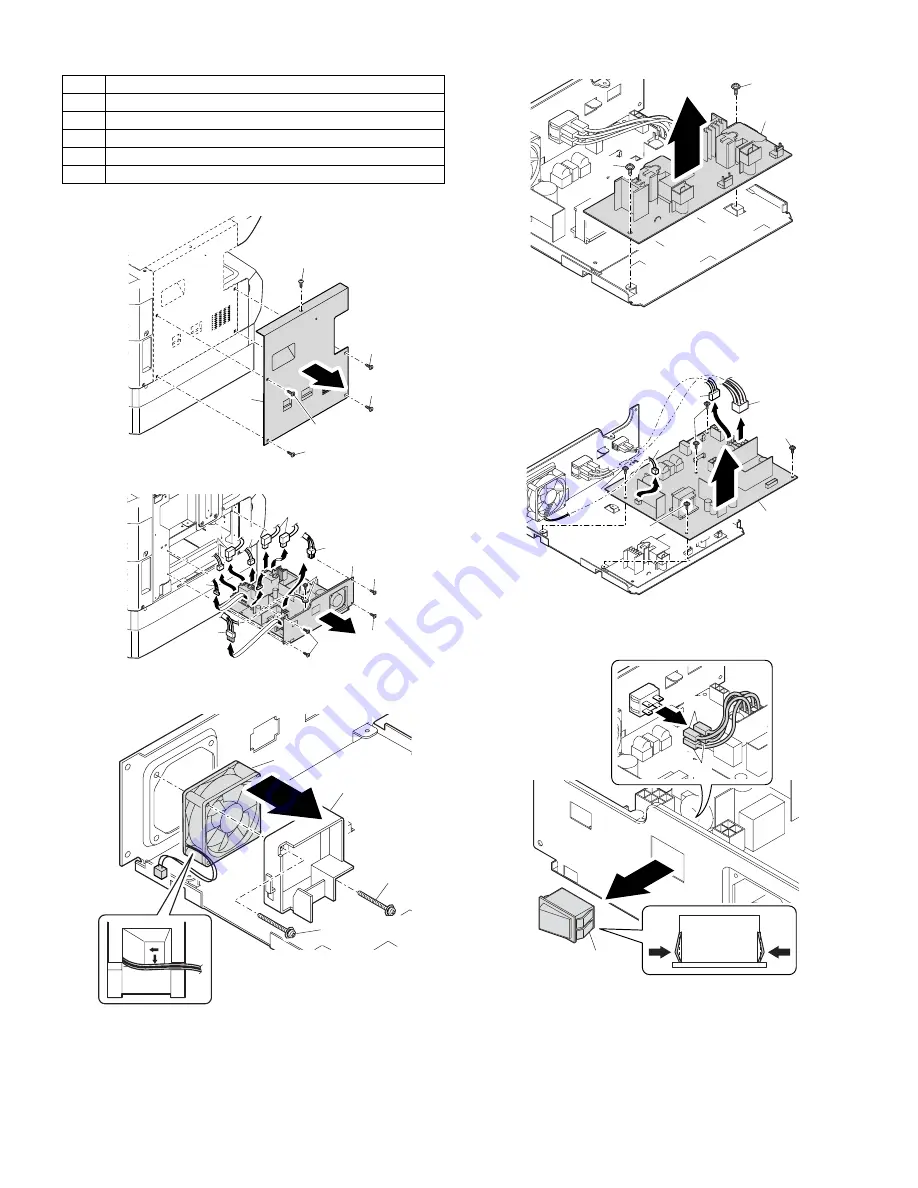

e-STUDIO161 DISASSEMBLY AND ASSEMBLY

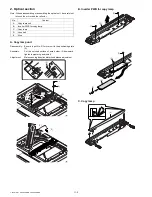

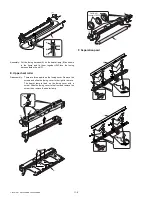

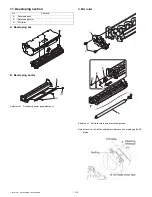

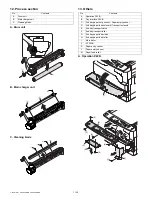

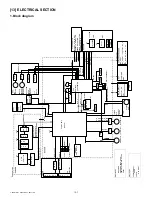

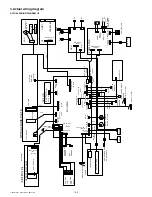

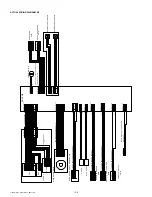

10. Power section

A. Power unit

B. Power fan

C. High voltage P.W.B.

D. Power P.W.B.

E. Power switch

No.

Content

A

Power unit

B

Power fan

C

High voltage P.W.B.

D

Power P.W.B.

E

Power switch

(1)

(1)

(1)

(1)

(2)

(1)

(1)

(2)

(3)

(1)

(1)

(2)

(2)

(2)

(2)

(2)

(2)

(3)

(2)

(1)

(1)

(1)

(2)

(1)

(1)

(1)

(2)

(2)

(3)

(2)

(2)

(1)

(1)

(1)

(2)

[11]DISASSEMBLY.fm 13 ページ 2004年1月9日 金曜日 午後1時21分