2-98

Service Manual

5060-XXX

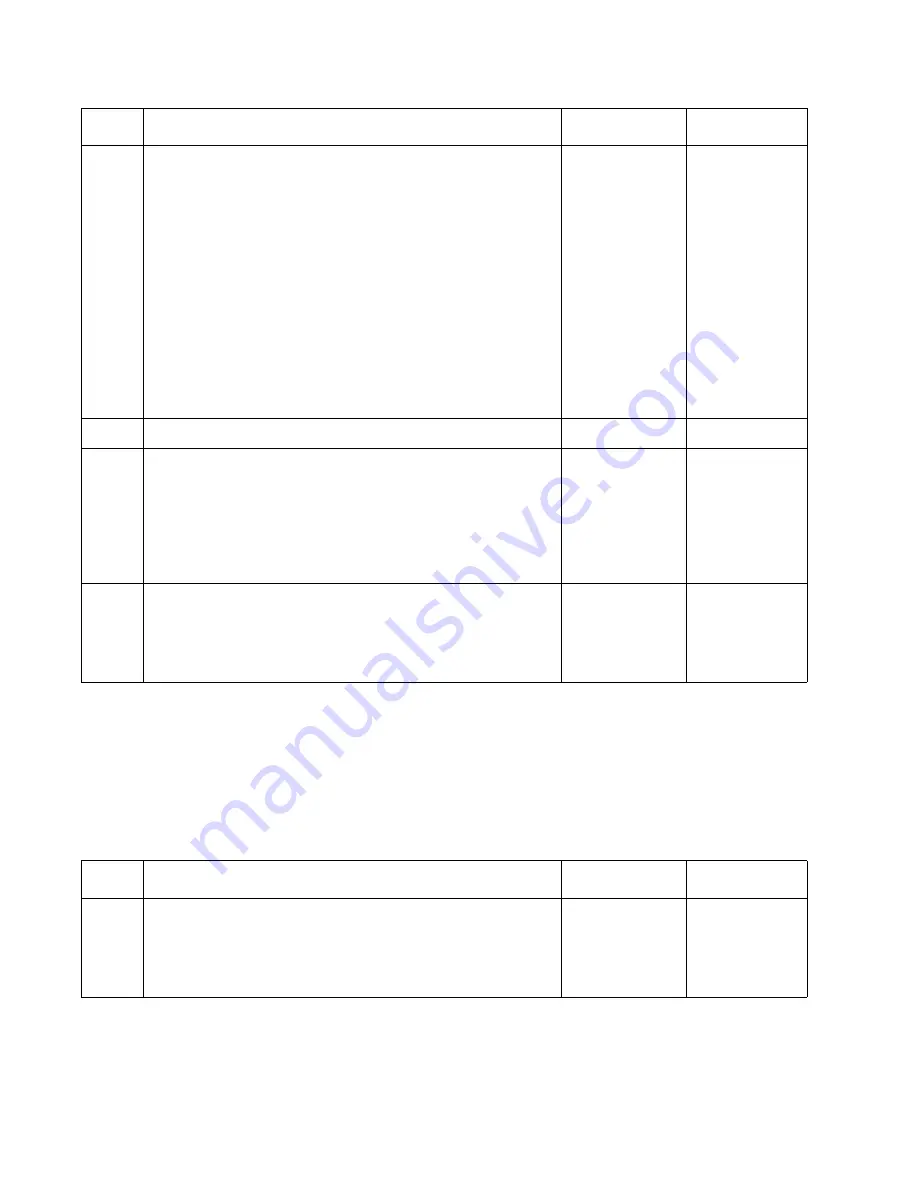

Tray 1 Service Check

Tray 1 does not stay seated or fit correctly in the printer, the media

fails to feed correctly from Tray 1 or Tray 1 is difficult to install

Note: The Tray 1 Feed Test in the CE Diagnostics can be used to help isolate problems

with paper feeding from Tray 1.

5

Check the following parts to make sure they are installed

correctly and they

are not damaged or broken.

* Size Sensing Gear Cover

* Size Sensing Gear

* Size Sensing Barrel Cam

Note: Make sure the Size Sensing Barrel Cam is correctly

installed. The position of the Cam tab can be observed

through the size sensing gear cover. The cam position can

be observed through the cover by moving the back restraint

and observing the cam detent. In the A5 media position the

detent should be visible through the opening in the gear

cover.

Are all the parts installed correctly, and not broken or

missing?

Go to step 6

Repair or

replace parts

as necessary

6

Is the answer to Step 3 "Yes"

Replace Tray 1

Go to step 7

7

Check the following parts in the printer to make sure they

are operating correctly. Check for any signs of broken or

missing parts.

* Size Sensing Springs

* Size Sensing Links

* Size Sensing Bracket

Is there any sign of broken or missing parts?

Repair or

replace parts

as necessary

Go to step 8

8

Check Paper Size Sensing assembly in the printer to make

sure that the Size Sensing Links correctly actuate the paper

size switches on the Engine Board.

Does Tray 1 correctly actuate the paper size switches on the

Engine Board?

Replace the

“Engine

Board” on

page 4-14

Repair or

replace parts

as necessary

Step

Action and Questions

Yes

No

1

Check the following parts in Tray 1 for any signs of Broken

or missing parts.

Tray Bias Spring loose or missing

Tray Bias Bellcrank

Are any parts broken, loose or missing?

Repair or

replace parts

as necessary

Go to step 2

Step

Action and Questions

Yes

No

Summary of Contents for e-STUDIO 20CP

Page 2: ...COLORPRINTER e STUDIO20CP ...

Page 3: ... ii ...

Page 5: ......

Page 19: ...xvi Service Manual 5060 XXX ...

Page 37: ...1 18 Service Manual 5060 XXX ...

Page 161: ...2 124 Service Manual 5060 XXX ...

Page 200: ...Repair Information 4 15 5060 XXX 4 Remove the right rear cover screw type 121 on page 4 4 A ...

Page 246: ...Connector Locations 5 17 5060 XXX RIP Board ...

Page 254: ...Connector Locations 5 25 5060 XXX HVPS Board ...

Page 256: ...Connector Locations 5 27 5060 XXX HVPS Developer Board ...

Page 257: ...5 28 Service Manual 5060 XXX ...

Page 261: ...7 2 Service Manual 5060 XXX Assembly 1 Covers ...

Page 263: ...7 4 Service Manual 5060 XXX Assembly 1 1 Covers ...

Page 269: ...7 10 Service Manual 5060 XXX Assembly 5 Paper Feed Output Redrive ...

Page 271: ...7 12 Service Manual 5060 XXX Assembly 6 Multipurpose Feeder MPF ...

Page 273: ...7 14 Service Manual 5060 XXX Assembly 7 500 Sheet Integrated Tray ...

Page 277: ...7 18 Service Manual 5060 XXX Assembly 9 1 ITU Assembly ...

Page 279: ...7 20 Service Manual 5060 XXX Assembly 10 Cartridge Contact Assembly ...

Page 281: ...7 22 Service Manual 5060 XXX Assembly 11 Electronics ...

Page 283: ...7 24 Service Manual 5060 XXX Assembly 11 1 Electronics ...

Page 291: ...7 32 Service Manual 5060 XXX Assembly 12 Output Expander ...

Page 293: ...7 34 Service Manual 5060 XXX Assembly 12 1 Output Expander ...

Page 295: ...7 36 Service Manual 5060 XXX Assembly 13 5 Bin Mailbox ...

Page 297: ...7 38 Service Manual 5060 XXX Assembly 13 1 5 Bin Mailbox ...

Page 299: ...7 40 Service Manual 5060 XXX Assembly 14 500 Sheet Tray Option ...

Page 301: ...7 42 Service Manual 5060 XXX Assembly 14 1 500 Sheet Tray Option ...

Page 303: ...7 44 Service Manual 5060 XXX Assembly 15 Duplex Unit ...

Page 305: ...7 46 Service Manual 5060 XXX Assembly 15 1 Duplex Unit ...

Page 307: ...7 48 Service Manual 5060 XXX Assembly 16 HCIT ...

Page 309: ...7 50 Service Manual 5060 XXX Assembly 16 1 HCIT ...

Page 323: ...I 8 Service Manual 5060 XXX ...