© 2003 - 2008 TOSHIBA TEC CORPORATION All rights reserved

e-STUDIO350/352/353/450/452/453

ADJUSTMENT

3 - 5

3

3.2.2

Paper alignment at the registration roller

The aligning amount is adjusted by using the following codes in Adjustment Mode (05).

Sub-code

*1 0: Long size

1: Middle size

2: Short size

*2 0: Long size

1: Middle size

2: Short size

3: Post card

*3 0: Long size of OHP film 1: Middle size of OHP film 2: Short size of OHP film

Notes:

1. Long size: 330 mm or longer (13.0 inches or longer)

Middle size: 220 - 239 mm (8.7 - 12.9 inches)

Short size: 219 mm or shorter (8.6 inches or shorter)

2. The adjustment of "Post card" is for Japan only.

<Procedure>

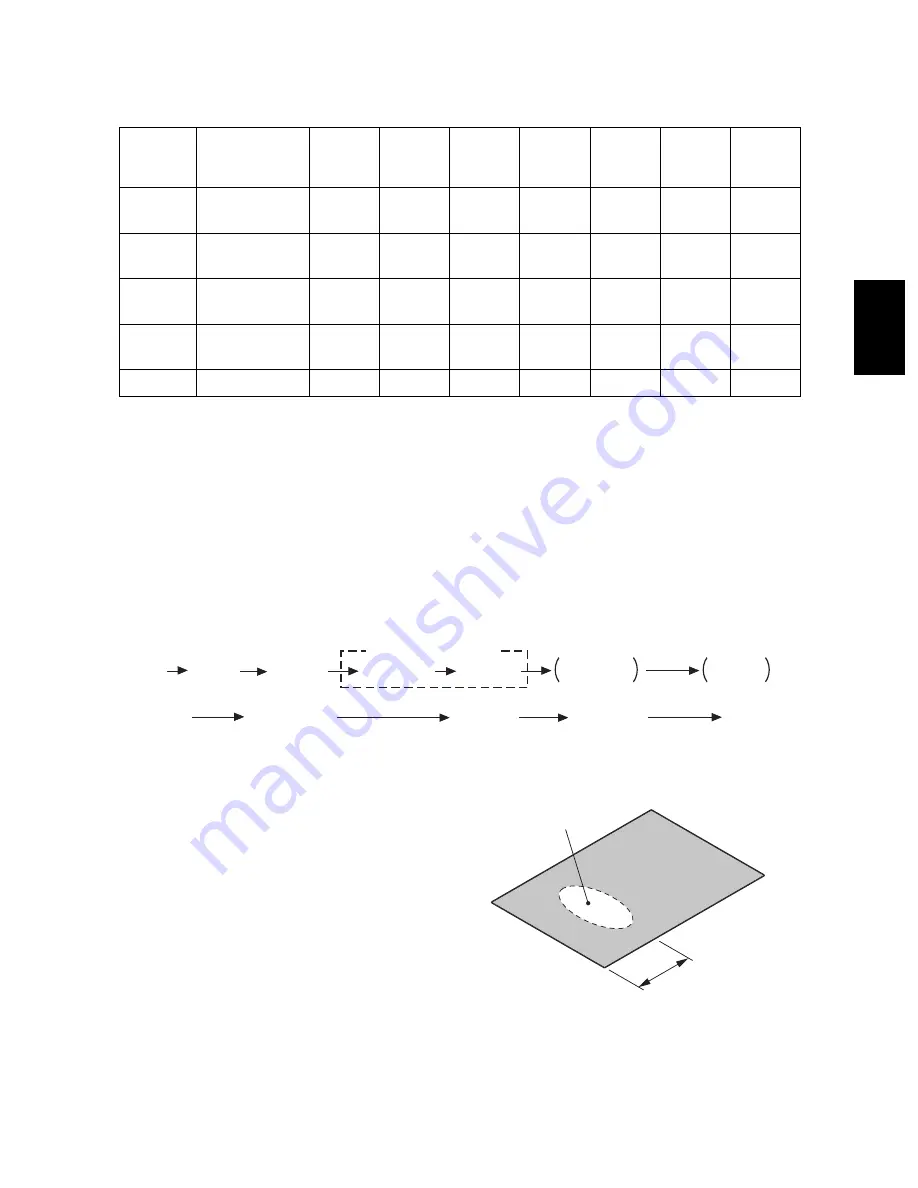

(1) Perform the test print according to the following procedure.

(*4) 1: Single-sided grid pattern 3: Double-sided grid pattern

(3) Perform the same procedure for all paper sources.

Paper

type

Weight

Upper

drawer

Lower

drawer

PPP

upper

drawer

PPP

lower

drawer

LCF

ADU

Bypass

feed

Plain

paper

64 - 80 g/m

2

17 - 20 lb.

450 (*1)

452 (*1)

448 (*1)

449 (*1)

457

455 (*1)

458 (*1)

Thick

paper 1

81 - 105 g/m

2

21 - 28 lb.

469 (*1)

470 (*1)

471 (*1)

472 (*1)

473

474 (*1)

460 (*1)

Thick

paper 2

106 - 163 g/m

2

29 - 43 lb.

-

-

-

-

-

-

461 (*1)

Thick

paper 3

164 - 209 g/m

2

44 - 55 lb.

-

-

-

-

-

-

462 (*2)

OHP

-

-

-

-

-

-

-

463 (*3)

(2) Check if any transfer void is occurring. If

there is a transfer problem, try the values in

descending order as “31”

→

“30”

→

“29”···

until the transfer void disappears. At the

same time, confirm if any paper jam occurs.

Also, when the aligning amount has been

increased, this may increase the scraping

noise caused by the paper and the Mylar

sheet as it is transported by the registration

roller. If this scraping noise is annoying, try to

decrease the value.

Fig. 3-1

(Code) [START] (Sub-code)

[START]

[0][5]

[Power]

Current value

displayed

Enter new

value

[POWER]

OFF/ON

(Exit)

[Drawer

selection]

(*3) +[FAX]

(Test print)

[SET] or

[INTERRUPT]

Stores in memory

(Not necessary for LCF)

50mm - 100mm

Transfer void