e-STUDIO350/352/353/450/452/453

© 2003 - 2008 TOSHIBA TEC CORPORATION All rights reserved

ADJUSTMENT

3 - 72

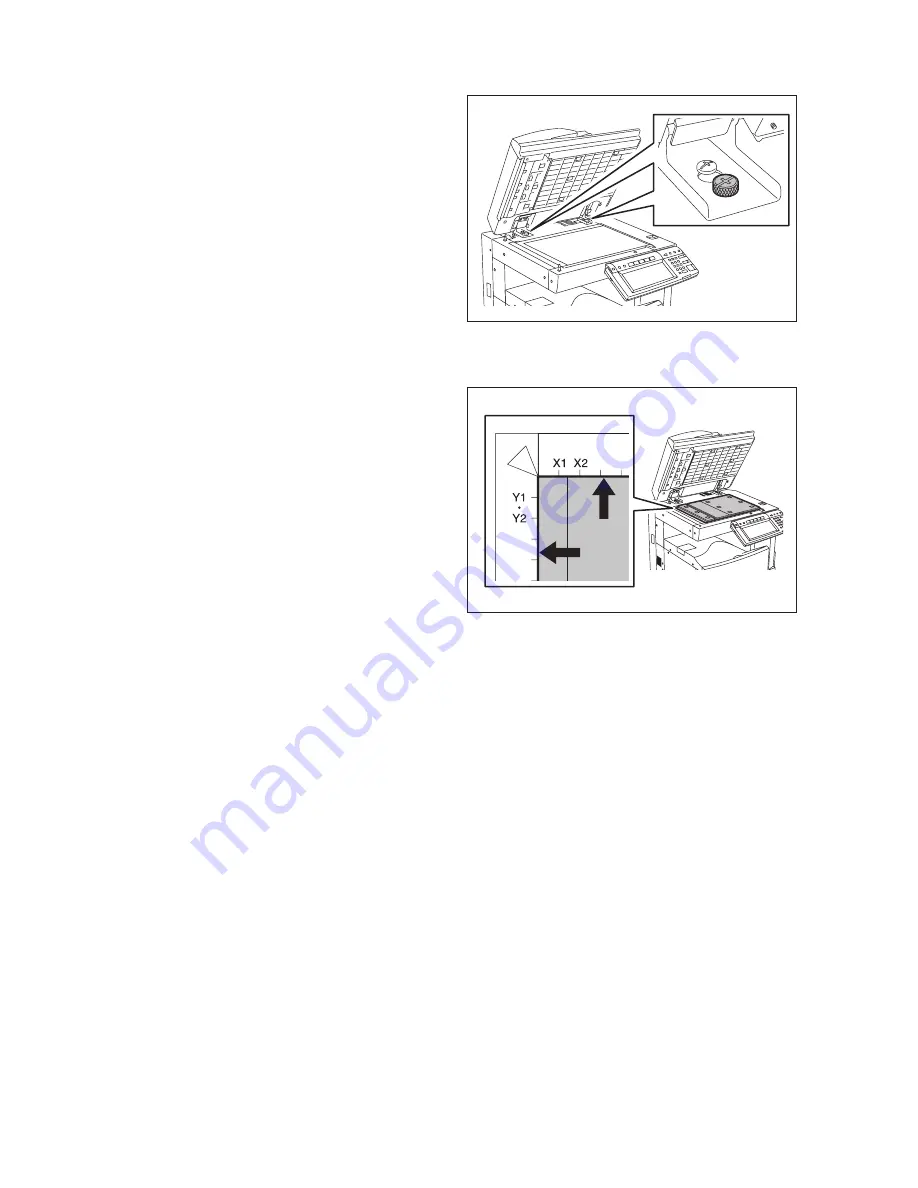

(9) Loosen the hinge screws at the front side.

Fig. 3-95

(10) Place the platen sheet on the original glass

and align it to the top left corner.

Close the RADF gently and open it to check

if the platen sheet is attached properly.

Fig. 3-96

05/11