e-STUDIO350/352/353/450/452/453

© 2003 - 2008 TOSHIBA TEC CORPORATION All rights reserved

PREVENTIVE MAINTENANCE (PM)

4 - 6

4.1.3

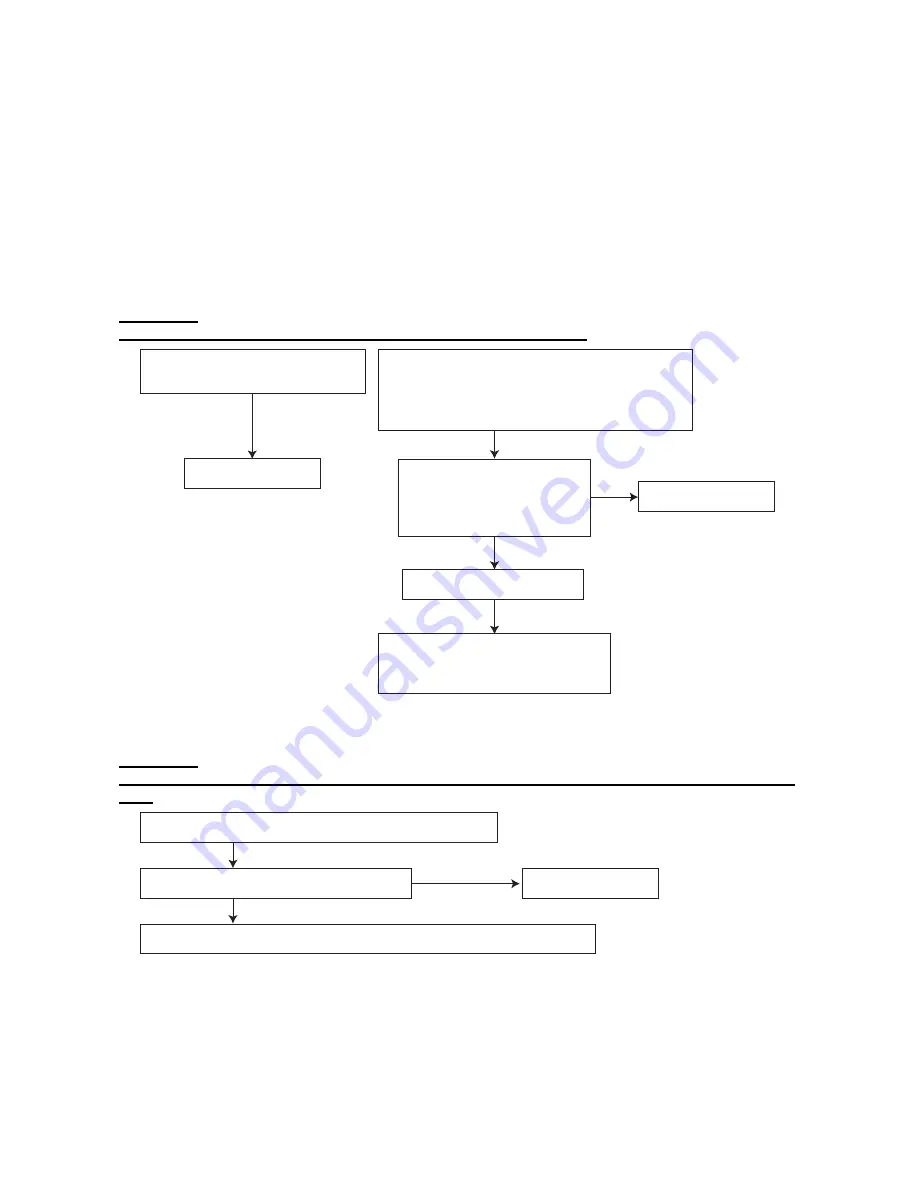

Work flow of parts replacement

The timing for the parts replacement usually depends on the number of output pages ever made after

they were replaced before. However, its drive counts time is also to be considered when replacing the

parts.

Even if the number of output pages has reached the level of replacement, for instance, the part may still

be usable with its drive counts not reaching the specified drive counts. On the other hand, the part may

need replacement even if the number of output pages has not reached the level of replacement with its

driving time exceeding the specified drive counts. The life span of some parts such as feed roller is

heavily dependent on the number of output pages rather than the drive counts.

The following work flow diagram shows how to judge the timing of replacement with the number of out-

put pages and the drive counts.

Example 1:

When the number of output pages has reached the specified level

Fig. 4-5

Example 2:

When the image failure occurred before the number of output pages has reached the specified

level

Fig. 4-6

• The parts in RADF

• The parts in feeding system

• The parts in the drum/cleaner unit

• The parts in the fuser unit

• The parts in the developer unit

• The parts in the transfer/separation charger unit

Replace the part.

Replace the part.

Check the drive counts at PM

support mode.

Does it exceed the specified

drive counts?

Replace the part after the drive

counts has reached the specified

count.

Yes

No

The part is still usable.

Replace the part.

Yes

No

Check the drive counts of all parts at PM support mode.

Does it exceed the specified drive count?

Check the part and equipment according to the “TROUBLESHOOTING”.