3

© February 2007 TOSHIBA TEC CORPORATION All rights reserved

e-STUDIO167/207/237

COPY PROCESS

3 - 1

3.

COPY PROCESS

3.1

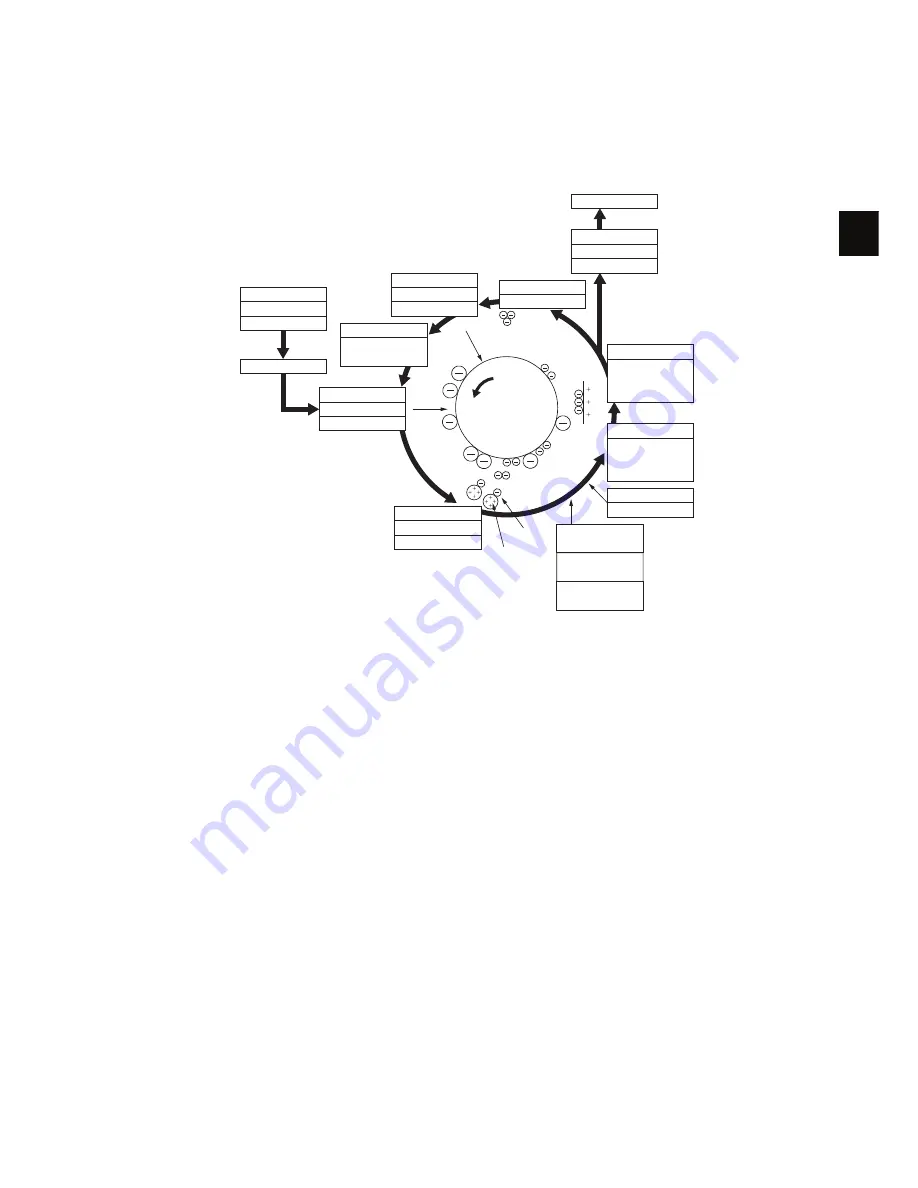

General Description of Copying Process

Fig. 3-1

(1)

Charging: Applies negative charge on the

surface of the photoconductive drum.

(7)

Separation: Separates paper with the toner

image from the photoconductive drum.

#

#

(2)

Data reading: The images on the original

are converted into electrical signals.

(8)

Fusing: Fuses the toner image onto the

paper by applying heat and pressure.

#

#

(3)

Data writing: The electrical signals are con-

verted into light signal (laser emission)

which exposes the surface of the photo-

conductive drum.

(9)

Cleaning: Scrapes off the residual toner

from the drum.

#

#

(4)

Development: Negatively-charged toner

adheres to the photoconductive drum and

forms visible image.

(10)

Discharging: Eliminates the residual nega-

tive charge from the surface of the photo-

conductive drum.

#

(5)

Transfer bias: Improves transfer efficiency.

#

(6)

Transfer: Transfers the visible toner image

on the photoconductive drum onto paper.

#

Data reading(scanning)

CIS

600 dpi,7084 pixel

Image processing

Discharging

Discharge LED (red)

Wavelength 660nm x10pcs

(10)

(8)

(7)

(6)

(5)

(9)

(2)

(1)

(3)

(4)

Data writing

Semiconductive laser

Pw=4.0 nJ/mm

2

Charging

e-STUDIO167/207:-448V

e-STUDIO237 :-454V

(grid voltage)

Development

Magnetic roller

Bias -AC

Toner

Carrier

Cleaning

Blade method

Bypass feeding

(100 sheets)

Drawer feeding

(250 sheets)

PFU

(250 sheets)

Transfer

H

340 µADC

C

369 µADC

L

282 µADC

Separation

H -107 µADC

Paper exit

Fusing

Lamp heating method

564W x2

Transfer bias

DC +565V

L -70 µADC

C -107 µADC