9

© 2009 TOSHIBA TEC CORPORATION All rights reserved

e-STUDIO182/212/242

PAPER FEEDING SYSTEM

9 - 17

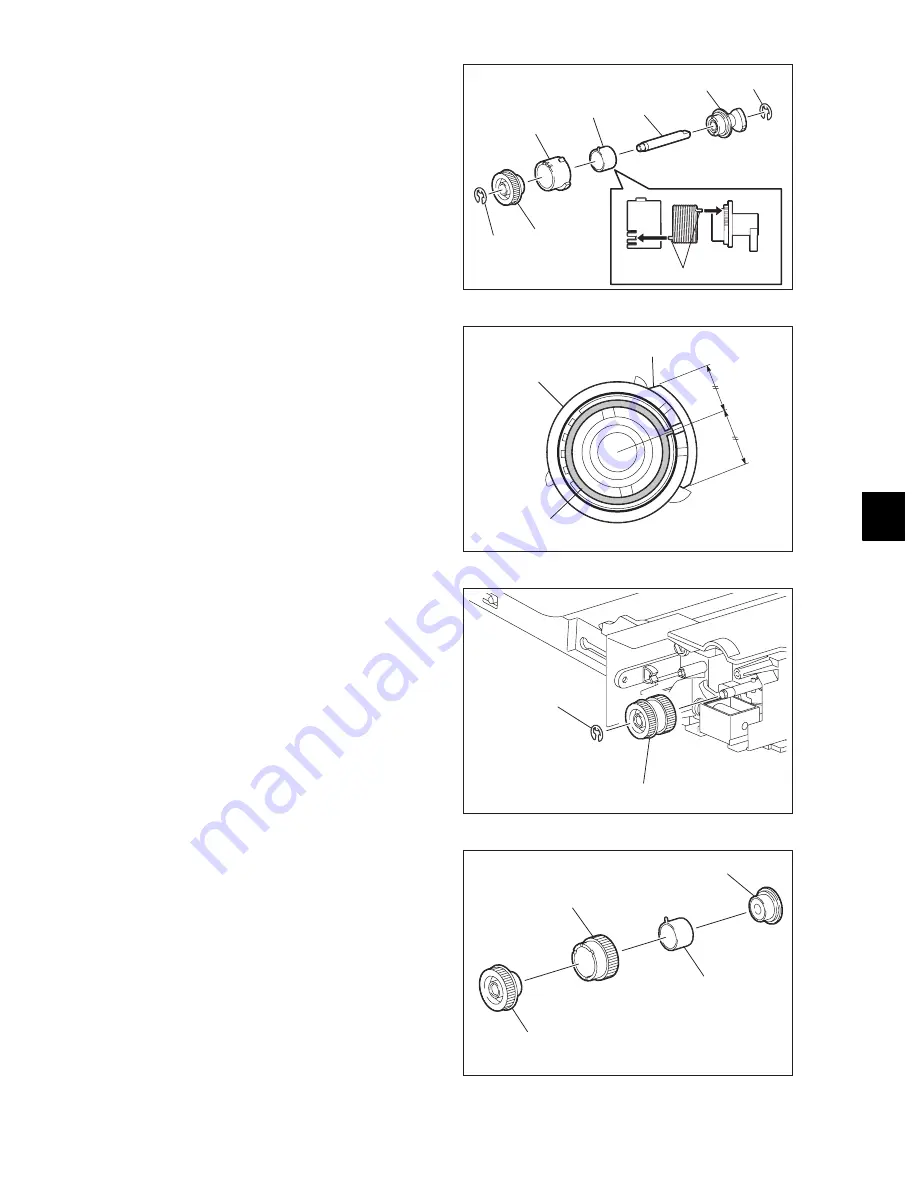

(4) Remove 2 E-rings. Then remove the gear,

cover, spring and cam out of the shaft.

Fig. 9-27

Note:

When assembling the bypass pickup clutch,

be sure to adjust the position of the hook of

the spring and cover so that the center slit of

the cover and the center of the cam are

aligned.

Fig. 9-28

(5) Remove 1 E-ring, and take off the bypass

feed clutch.

Fig. 9-29

(6) Remove the gear, cover, spring and cap.

Fig. 9-30

Cam

E-ring

E-ring

Gear

Shaft

Spring

Cover

Hook

Cam

Cover

Spring

Bypass feed clutch

E-ring

Cover

Gear

Spring

Cap

Summary of Contents for e-studio182

Page 12: ......

Page 18: ...e STUDIO182 212 242 2009 TOSHIBA TEC CORPORATION All rights reserved CONTENTS 6 ...

Page 76: ...e STUDIO182 212 242 2009 TOSHIBA TEC CORPORATION All rights reserved COPY PROCESS 3 14 ...

Page 120: ...e STUDIO182 212 242 2009 TOSHIBA TEC CORPORATION All rights reserved SCANNER 6 26 ...

Page 128: ...e STUDIO182 212 242 2009 TOSHIBA TEC CORPORATION All rights reserved LASER OPTICAL UNIT 7 8 ...

Page 228: ...e STUDIO182 212 242 2009 TOSHIBA TEC CORPORATION All rights reserved FUSER EXIT UNIT 12 24 ...

Page 257: ......

Page 258: ......