5

© 2008 - 2011 TOSHIBA TEC CORPORATION All rights reserved

e-STUDIO2020C/2330C/2820C/2830C/3520C/3530C/4520C

PREVENTIVE MAINTENANCE (PM)

5 - 41

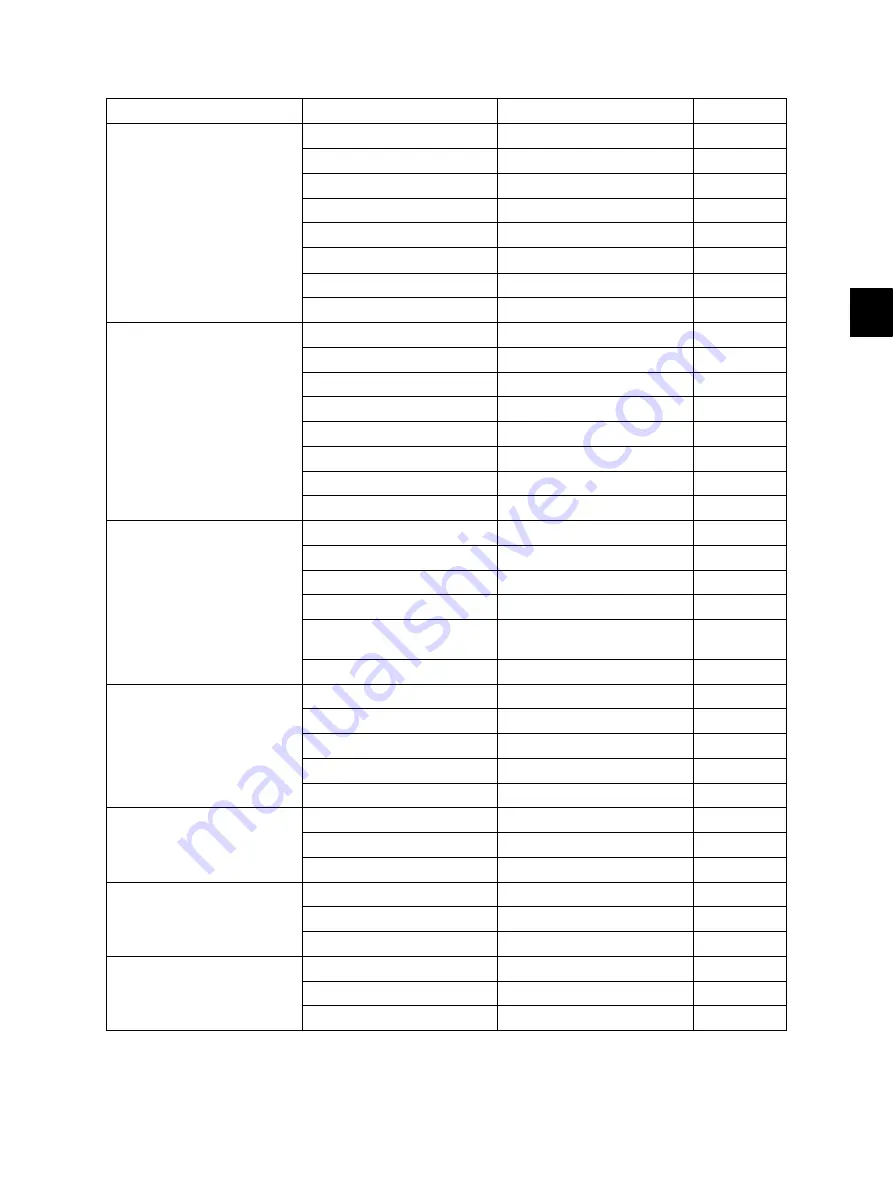

5.8

PM KIT

A PM kit is a package for each unit of replacement parts requiring PM.

KIT name

Component

Part name

Qty.

DEV-KIT-FC28K-N

Drum cleaning blade

BL-FC28D

1

Main charger grid

GRID-CHARGR-MAIN-F45X

1

Needle electrode

ELCTRD-CHARGR-MAIN-380

1

Main charger cleaner

FILM-CLNR-GRID-F45X

2

Developer material

D-FC28-K

1

Developer unit filter

ASYS-DUCT-DEV-COV

1

Ozone filter 1

FLTR-OZON-45X-CBO-600M

1

Slit glass cleaner pad

ASYS-CLNR-GLASS

1

DEV-KIT-FC28CLR-N

Drum cleaning blade

BL-FC28D

3

Main charger grid

GRID-CHARGR-MAIN-F45X

3

Needle electrode

ELCTRD-CHARGR-MAIN-380

3

Main charger cleaner

FILM-CLNR-GRID-F45X

6

Developer material (Y)

D-FC28-Y

1

Developer material (M)

D-FC28-M

1

Developer material (C)

D-FC28-C

1

Developer filter

ASYS-DUCT-DEV-COV

3

TBU-KIT-FC28

Transfer belt cleaning blade

BL-FC35TR

1

2nd transfer roller

CR-FC35TR2

1

Blade seal (front side)

SEAL-BLADE-CLN-TBU-F

1

Blade-seal (rear side)

SEAL-BLADE-CLN-TBU-R

1

2nd transfer facing roller

cleaning Mylar

MYLAR-CLN-TR2-WP-450

1

Ozone filter 2

FLTR-OZ-50-TNR-EX-450

1

FR-KIT-FC28

Fuser belt

BT-FC35-FU

1

Fuser roller

FR-FC28-U

1

Press roller

HR-FC28-L

1

Separation finger

SCRAPR-FUS-350

5

Fuser belt guide

COLLAR-HR-T1

2

PM-KIT-ROLLER

Pick up roller

ROLLER-PICK-AT

1

Feed roller

K-ROLL-FEED

1

Separation roller

ASYS-ROLL-SPT

1

ROL-KIT-1010

Pick up roller

ROL-PICK-UP

1

Feed roller

ROL-PAPER-FED-F

1

Separation roller

ROL-PAPER-FED-S

1

DF-KIT-3018

Pick up roller

ASYS-ROL-FEED

1

Feed roller

ASYS-ROL-FEED

1

Separation roller

ASYS-ROL-RET

1