2-98

Service Manual

The elevator tray does not move up or down; the printer recognizes that the option is

installed

The elevator moves in one direction only

FRU

Action

1

DC drive motor high-

capacity feeder option

system board

Be sure the motor cable is correctly installed at J1 on the board.

Check the cables, damaged or loose wires. Disconnect the motor.

Check for a short between each pin and the motor housing. If a

problem is found, replace the motor assembly. If no problem is found,

measure the resistance between the following pins on the motor

cable connector:

Pins 1 (brown) and pin 2 (Yellow)

The resistance measures between approximately 7.5 and 10.5 ohms.

If incorrect, replace the motor assembly. If correct, replace the high-

capacity feeder option system board.

FRU

Action

1

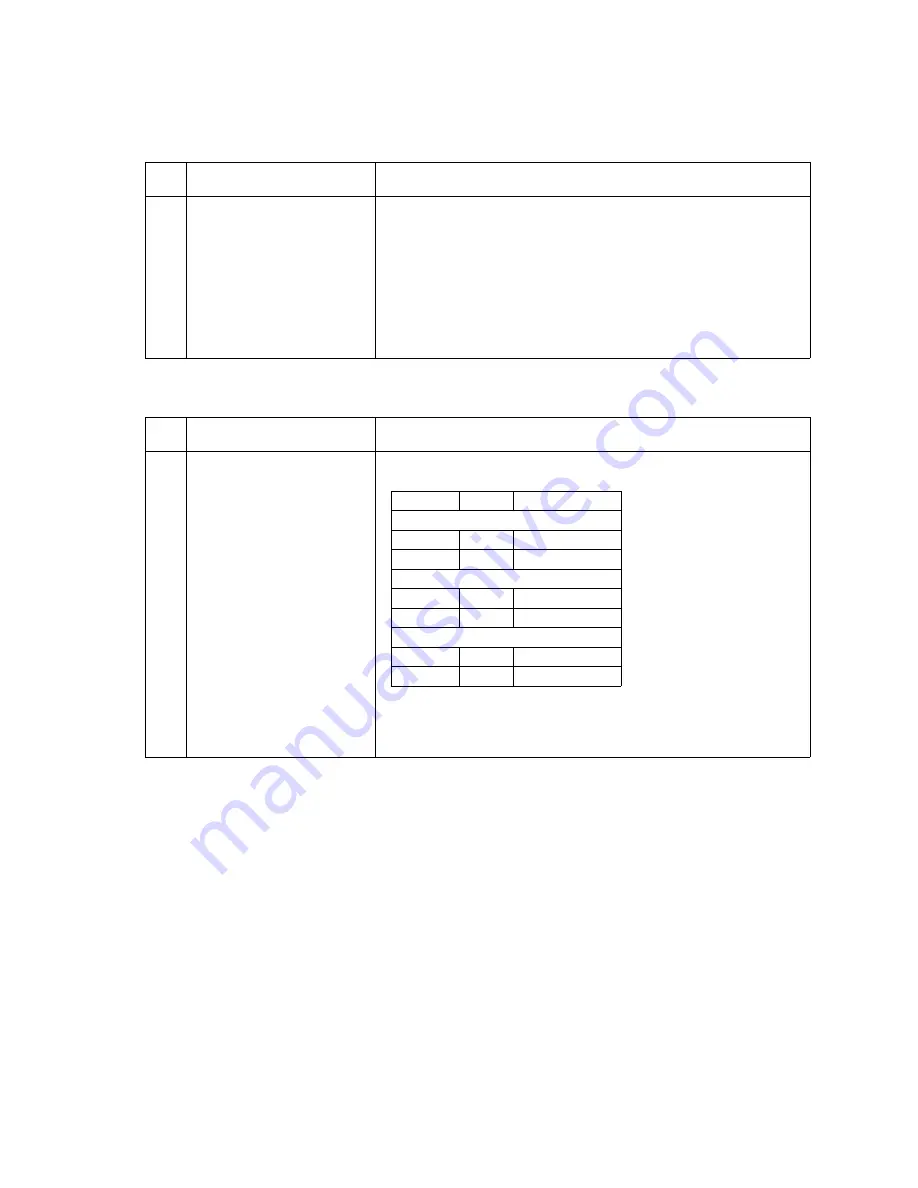

DC drive motor assembly

high-capacity feeder

system board

Check the voltages at J1 on the high-capacity system board. The

voltages measure approximately as follows:

If any of the voltages are incorrect, disconnect the motor and

measure the resistance between J-1 and J-2. The resistance

measures between 7.5 and 10.5 ohms. If incorrect, replace the

motor. If correct, replace the system board.

Pin

Color

Voltage

Static (motor not running)

J1-1

Brown

0 V dc

J1-2

Yellow

0 V dc

Motor running forward

J1-1

Brown

0 V dc

J1-2

Yellow

+24 V dc

Motor running in reverse

J1-1

Brown

+24 V dc

J1-2

Yellow

0 V dc

Summary of Contents for e-STUDIO500P

Page 1: ...PRINTER P N 12G9609 e STUDIO500P ...

Page 10: ...x Service Manual ...

Page 15: ...Laser notices xv Japanese Laser Notice ...

Page 16: ...xvi Service Manual Korean Laser Notice ...

Page 43: ...Diagnostic information 2 7 ...

Page 159: ...Diagnostic information 2 123 ...

Page 160: ...2 124 Service Manual ...

Page 161: ...Diagnostic information 2 125 ...

Page 181: ...Diagnostic aids 3 17 ...

Page 297: ...5 12 Service Manual ...

Page 298: ...Connector locations and connections 5 13 ...

Page 299: ...5 14 Service Manual ...

Page 301: ...6 2 Service Manual ...

Page 303: ...7 2 Service Manual Assembly 1 Covers ...

Page 305: ...7 4 Service Manual Assembly 2 Frame 1 ...

Page 307: ...7 6 Service Manual Assembly 3 Frame 2 ...

Page 309: ...7 8 Service Manual Assembly 4 Frame 3 ...

Page 311: ...7 10 Service Manual Assembly 5 Printhead ...

Page 313: ...7 12 Service Manual Assembly 6 Paper feed autocompensator ...

Page 315: ...7 14 Service Manual 4061 xx0 Assembly 7 Paper feed multipurpose feeder ...

Page 317: ...7 16 Service Manual Assembly 8 Paper feed alignment ...

Page 319: ...Page 7 19 has been removed from this document intentionally 7 18 Service Manual ...

Page 320: ...7 20 Service Manual Assembly 10 Integrated 500 sheet paper tray ...

Page 322: ...7 22 Service Manual Assembly 11 Drives Main drive and developer drive ...

Page 324: ...7 24 Service Manual Assembly 12 Hot roll fuser ...

Page 326: ...7 26 Service Manual Assembly 13 Transfer charging ...

Page 328: ...7 28 Service Manual Assembly 14 Electronics power supplies ...

Page 330: ...7 30 Service Manual Note ...

Page 332: ...7 32 Service Manual Assembly 16 Electronics shields ...

Page 336: ...7 36 Service Manual Assembly 19 Cabling diagrams 3 ...

Page 338: ...7 38 Service Manual Assembly 20 Cabling diagrams 4 ...

Page 340: ...7 40 Service Manual Assembly 21 Cabling diagrams 5 ...

Page 342: ...7 42 S ervice Manual THE FOLLOWING PAGE 7 43 HAS BEEN OMITTED FROM THIS MANUAL INTENTIONALLY ...

Page 347: ...7 48 S ervice Manual Pages 7 49 through 7 57 of this manual have been omitted intentionally ...

Page 348: ...7 58 Service Manual Assembly 35 High capacity feeder 1 ...

Page 350: ...7 60 Service Manual Assembly 36 High capacity feeder 2 ...

Page 354: ...7 64 S ervice Manual Pages 7 65 thru 7 70 ofthis manual were omitted intentionally ...

Page 362: ...I 8 Service Manual ...

Page 370: ...I 16 Service Manual ...