2-122

Service Manual

Printhead service check

CAUTION:

The printhead is not a serviceable FRU. Do not disassemble the printhead.

The printhead assembly does not contain any service replaceable parts or components. If service error code

930.xx displays, the wrong printhead is installed in the printer. See

“Printhead” on page 7-10

.

Note:

A 201.xx paper jam may also indicate a failing printhead. The paper may have jammed prior to or at the

input sensor. Print the event log and see if 201 or 931 errors are logged.

Signature button assembly service check

Note:

If you are unable to clear a

32.xx-Unsupported Cartridge

User Error message, be sure a

Lexmark T64x print cartridge is correctly installed in the printer. The cartridge is easily identified by the contact

board on the right side rear of the cartridge. Install another print cartridge before attempting to troubleshoot the

printer. Make sure the signature button cable is properly connected to J14 on the system board. Check the print

cartridge for damage or improper installation of the chip. Also, be sure there is proper contact between the chip

on the cartridge and the signature button contact assembly.

Service tip: An intermittent

32.xx-Unsupported Cartridge

User Error message can be caused by poor

contact between the signature button cartridge contacts in the upper front cover and the chip. Also check for

proper seating of the signature button cartridge cable to the system board.

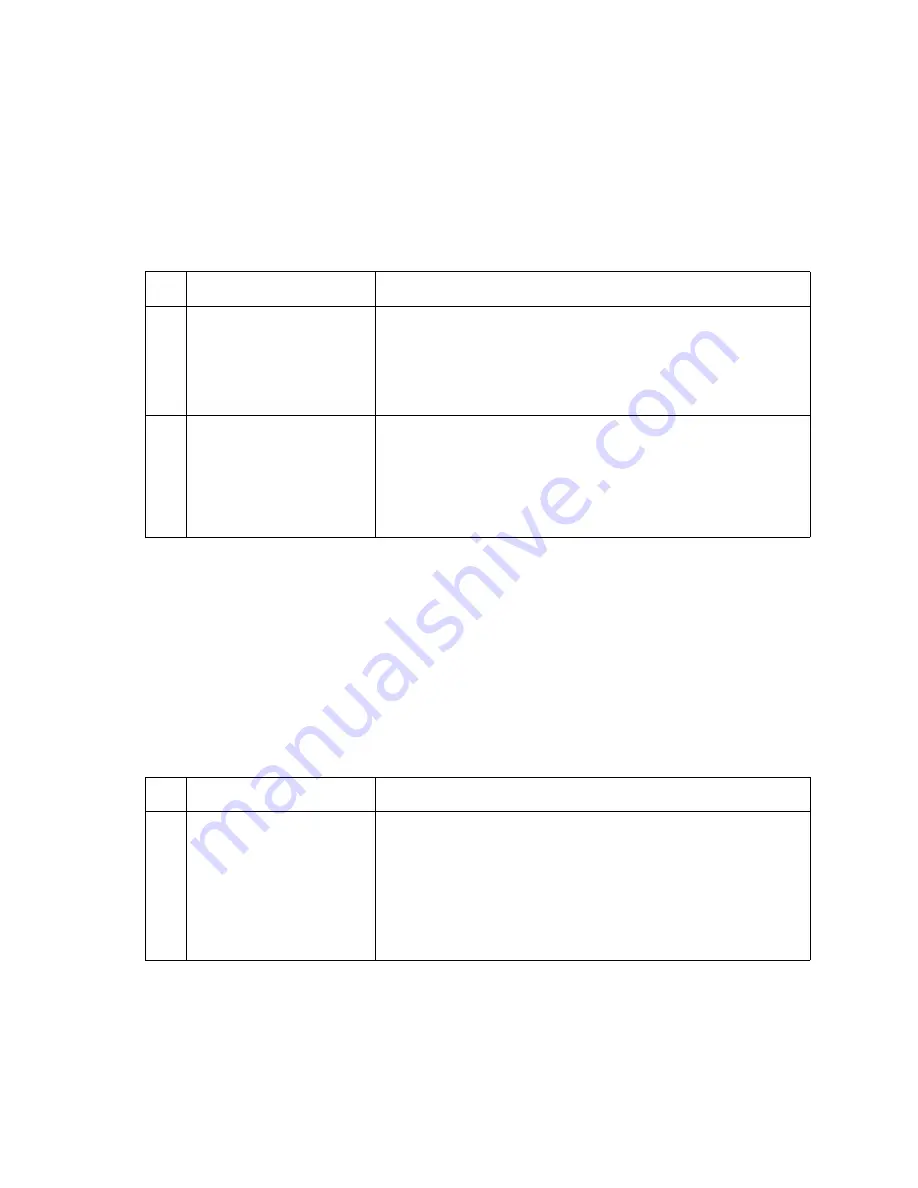

Service error code

Explanation

1

Error code 931.xx

No first HYSNC Signal

Error Code 932

Lost HYSNC

These errors usually indicate a failure in the HYSNC signal to the

printhead. Check the continuity of the cables connected to J2 and J4

on the system board. If incorrect, replace the defective cable. The

voltage at J4-1 measures approxi5 V dc. If incorrect, replace

the system board. The voltage at J2-7 measures approximately

+24 V dc. If incorrect, replace the system board. If correct, replace

the printhead assembly.

2

Error Code 934.xx

Mirror motor lost lock Error

Code 935

Mirror motor unable to

reach operating speed

These error codes indicate a problem with the mirror motor circuit in

the printhead assembly or the mirror motor cable to the system board

cable or system board assembly. The voltage at J5-2 measures

approxi24 V dc. If incorrect, replace the system board. If

correct, replace the FRUs in the following order:

• System board

• Printhead assembly

FRU

Action

1

Signature button contact

assembly

System board

Check the voltage on the signature button cartridge contact. The

voltage measures approxi3.8 V dc when not writing data to

the system board. If data is being written, the voltage measures

approximately 0 V dc. If incorrect, disconnect the cable from J19 on

the system board, and check the voltage on J19-1. The voltage

measures approxi5 V dc.

• If incorrect, replace the system board.

• If correct, replace the signature button cartridge contact

assembly.

Summary of Contents for e-STUDIO500P

Page 1: ...PRINTER P N 12G9609 e STUDIO500P ...

Page 10: ...x Service Manual ...

Page 15: ...Laser notices xv Japanese Laser Notice ...

Page 16: ...xvi Service Manual Korean Laser Notice ...

Page 43: ...Diagnostic information 2 7 ...

Page 159: ...Diagnostic information 2 123 ...

Page 160: ...2 124 Service Manual ...

Page 161: ...Diagnostic information 2 125 ...

Page 181: ...Diagnostic aids 3 17 ...

Page 297: ...5 12 Service Manual ...

Page 298: ...Connector locations and connections 5 13 ...

Page 299: ...5 14 Service Manual ...

Page 301: ...6 2 Service Manual ...

Page 303: ...7 2 Service Manual Assembly 1 Covers ...

Page 305: ...7 4 Service Manual Assembly 2 Frame 1 ...

Page 307: ...7 6 Service Manual Assembly 3 Frame 2 ...

Page 309: ...7 8 Service Manual Assembly 4 Frame 3 ...

Page 311: ...7 10 Service Manual Assembly 5 Printhead ...

Page 313: ...7 12 Service Manual Assembly 6 Paper feed autocompensator ...

Page 315: ...7 14 Service Manual 4061 xx0 Assembly 7 Paper feed multipurpose feeder ...

Page 317: ...7 16 Service Manual Assembly 8 Paper feed alignment ...

Page 319: ...Page 7 19 has been removed from this document intentionally 7 18 Service Manual ...

Page 320: ...7 20 Service Manual Assembly 10 Integrated 500 sheet paper tray ...

Page 322: ...7 22 Service Manual Assembly 11 Drives Main drive and developer drive ...

Page 324: ...7 24 Service Manual Assembly 12 Hot roll fuser ...

Page 326: ...7 26 Service Manual Assembly 13 Transfer charging ...

Page 328: ...7 28 Service Manual Assembly 14 Electronics power supplies ...

Page 330: ...7 30 Service Manual Note ...

Page 332: ...7 32 Service Manual Assembly 16 Electronics shields ...

Page 336: ...7 36 Service Manual Assembly 19 Cabling diagrams 3 ...

Page 338: ...7 38 Service Manual Assembly 20 Cabling diagrams 4 ...

Page 340: ...7 40 Service Manual Assembly 21 Cabling diagrams 5 ...

Page 342: ...7 42 S ervice Manual THE FOLLOWING PAGE 7 43 HAS BEEN OMITTED FROM THIS MANUAL INTENTIONALLY ...

Page 347: ...7 48 S ervice Manual Pages 7 49 through 7 57 of this manual have been omitted intentionally ...

Page 348: ...7 58 Service Manual Assembly 35 High capacity feeder 1 ...

Page 350: ...7 60 Service Manual Assembly 36 High capacity feeder 2 ...

Page 354: ...7 64 S ervice Manual Pages 7 65 thru 7 70 ofthis manual were omitted intentionally ...

Page 362: ...I 8 Service Manual ...

Page 370: ...I 16 Service Manual ...