32

6

F

2

S

0

7

8

9

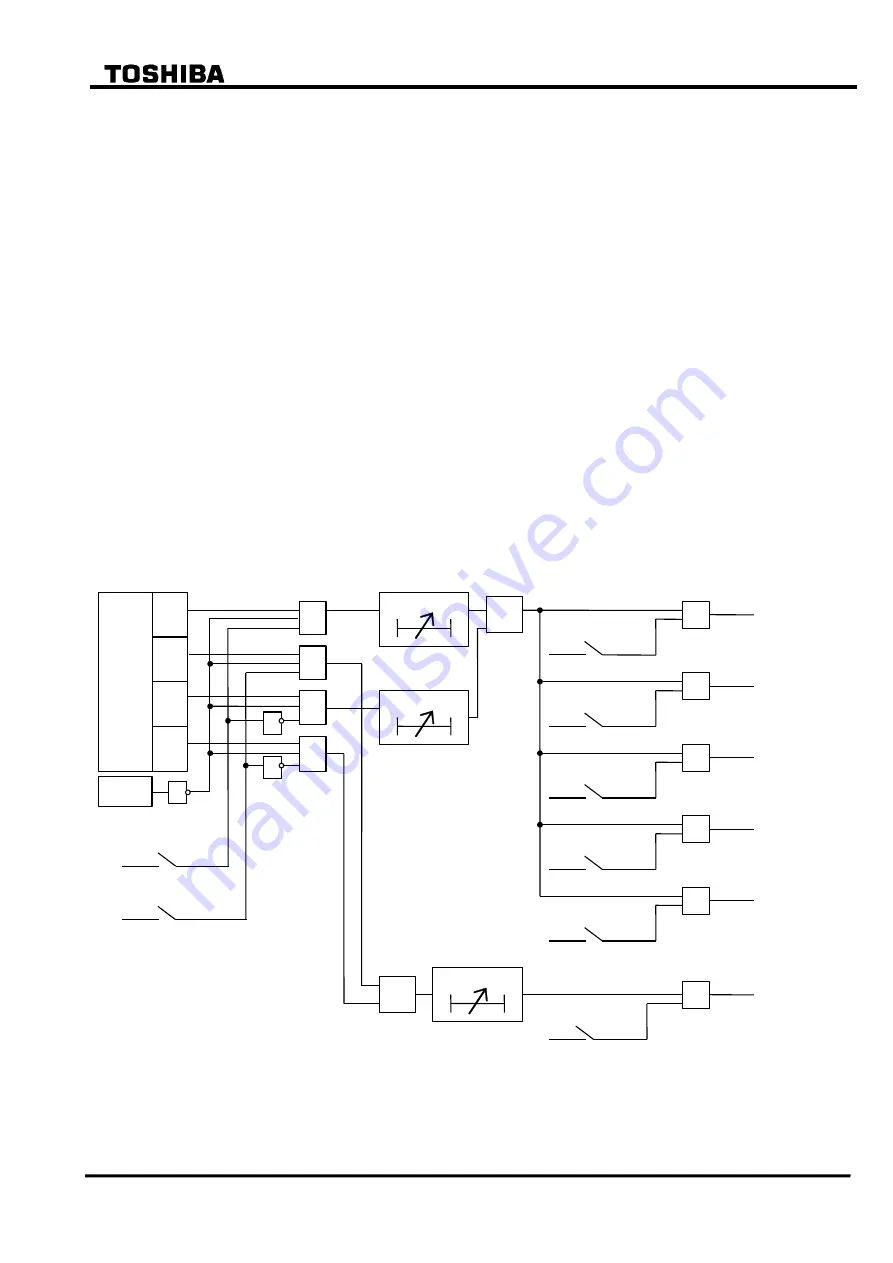

2.7 Frequency Protection

GRT100 provides an underfrequency or overfrequency protection and/or alarms for load

shedding or for detecting such an overfrequency condition caused by disconnecting load from a

particular generation location.

The frequency element FRQ comprises two frequency elements 81-1 and 81-2, the former is used

for tripping and the latter for alarms.

Figure 2.7.1 shows the scheme logic of frequency protection. The tripping element 81-1 outputs

underfrequency and overfrequency trip signals L1 and H1. Either underfrequency or

overfrequency protection is enabled by setting the scheme switch [FRQ-UF1] to “ON” or “OFF”.

The alarm element 81-2 outputs underfrequency and overfrequency alarm signals L2 and H2.

Either underfrequency or overfrequency alarms are enabled by setting the scheme switch

[FRQ-UF2] to “ON” or “OFF”.

Frequency protection can perform time-delayed tripping of up to five breakers. Any of the

breaker tripping signals FRQ-1 to FRQ-5 can be blocked by the scheme switch [FRQ1] to

[FRQ5] settings.

Alarm signal FRQ-A can be blocked by the scheme switch [FRQA] setting.

Frequency protection is blocked under the condition that the system voltage is lower than the

setting of the undervoltage element UV.

FRQ-1

1

1

TFRQL

0.00 - 60.00s

&

&

&

&

TFRQH

0.00 - 60.00s

0.00 - 60.00s

FRQ-2

FRQ-3

FRQ-4

FRQ-5

FRQ-A

[FRQA]

&

TFRQA

[FRQ1]

&

[FRQ2]

&

[FRQ3]

&

[FRQ4]

&

&

1

1

[FRQ5]

0

t

0

t

0

t

FRQ-UF1

FRQ-UF2

81-1

81-2

H1

H2

L2

L1

UV

1

“ON”

“ON”

“ON”

“ON”

“ON”

“ON”

“ON”

“ON”

FRQ

Figure 2.7.1 Scheme Logic of Frequency Protection

Summary of Contents for GRT100 Series

Page 142: ... 141 6 F 2 S 0 7 8 9 Appendix A Block Diagram ...

Page 144: ... 143 6 F 2 S 0 7 8 9 Appendix B Signal List ...

Page 159: ... 158 6 F 2 S 0 7 8 9 ...

Page 160: ... 159 6 F 2 S 0 7 8 9 Appendix C Variable Timer List ...

Page 162: ... 161 6 F 2 S 0 7 8 9 Appendix D Binary Output Default Setting List ...

Page 165: ... 164 6 F 2 S 0 7 8 9 ...

Page 166: ... 165 6 F 2 S 0 7 8 9 Appendix E Details of Relay Menu and LCD and Button Operation ...

Page 174: ... 173 6 F 2 S 0 7 8 9 Appendix F Case Outline Flush Mount Type Rack Mount Type ...

Page 179: ... 178 6 F 2 S 0 7 8 9 ...

Page 180: ... 179 6 F 2 S 0 7 8 9 Appendix G External Connections ...

Page 185: ... 184 6 F 2 S 0 7 8 9 ...

Page 200: ... 199 6 F 2 S 0 7 8 9 ...

Page 201: ... 200 6 F 2 S 0 7 8 9 Appendix J Return Repair Form ...

Page 205: ... 204 6 F 2 S 0 7 8 9 Customer Name Company Name Address Telephone No Facsimile No Signature ...

Page 206: ... 205 6 F 2 S 0 7 8 9 ...

Page 207: ... 206 6 F 2 S 0 7 8 9 Appendix K Technical Data ...

Page 220: ... 219 6 F 2 S 0 7 8 9 ...

Page 221: ... 220 6 F 2 S 0 7 8 9 Appendix M Symbols Used in Scheme Logic ...

Page 224: ... 223 6 F 2 S 0 7 8 9 ...

Page 225: ... 224 6 F 2 S 0 7 8 9 Appendix N Implementation of Thermal Model to IEC60255 8 ...

Page 228: ... 227 6 F 2 S 0 7 8 9 ...

Page 229: ... 228 6 F 2 S 0 7 8 9 Appendix O IEC60870 5 103 Interoperability and Troubleshooting ...

Page 241: ... 240 6 F 2 S 0 7 8 9 Appendix P Modbus Interoperability ...

Page 255: ... 254 6 F 2 S 0 7 8 9 ...

Page 256: ... 255 6 F 2 S 0 7 8 9 Appendix Q Inverse Time Characteristics ...

Page 259: ... 258 6 F 2 S 0 7 8 9 ...

Page 260: ... 259 6 F 2 S 0 7 8 9 Appendix R Failed Module Tracing and Replacement ...

Page 266: ... 265 6 F 2 S 0 7 8 9 Appendix S Ordering ...

Page 269: ... 268 6 F 2 S 0 7 8 9 3 1 Oct 2 2017 Republished under spin off company ...

Page 270: ......