MAINTENANCE

Page 19

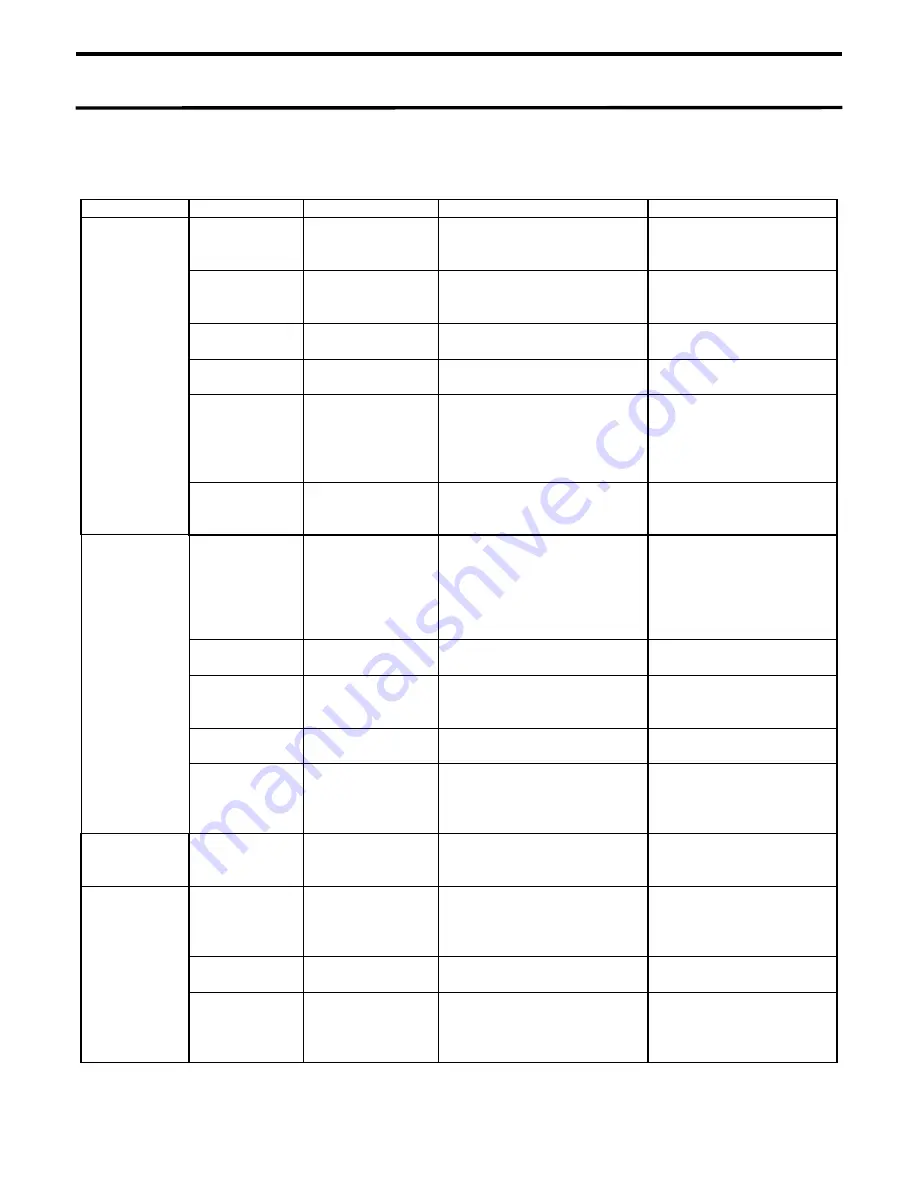

Table 2 - Check Points for Periodic Inspection

Check Point

Check Item

Check Method

Criteria

Disposition

Operating

Mechanism

Loose bolts,

nuts or screws

Tighten using

screwdriver or

wrench.

Make sure all bolts, nuts and

screws are tight.

Tighten if loose. See

Table 1 for tightening

torque specifications.

Dust or foreign

matter inside

Visual inspection. The contactor should be

clean and contain no foreign

matter.

Wipe with a clean dry

cloth.

Electro-

magnets

Visual inspection. Check for rust, discoloration,

wear, or loose mountings.

Wipe with a clean dry

cloth.

Closing coil

Visual inspection. Check for discoloration, and

burned parts.

Wipe with a clean dry

cloth.

Spring

Visual inspection. Check for rust, deformation,

discoloration, or damage.

Wipe with clean dry cloth.

Lubricate wipe surface if

needed or every 20,000

operations. (Toshiba B9

grease)

Smooth

operation

Visual inspection

or touch. Check

lubrication.

Make sure moving parts

operate smoothly.

Apply a small amount of

lubrication. (Toshiba B9

grease)

Main Circuit

Terminals and

movable

conductors.

Visual inspection.

Tighten using

screwdriver or

wrench.

Make sure there is no

discoloration or loose

fasteners.

Check the cause and

repair. Tighten

connections to the

contactor. See

Table 1 for tightening

torque specifications.

Loose bolts,

nuts or screws

Tighten using a

wrench.

Make sure all bolts, nuts and

screws are tight.

See Table 1 for tightening

torque specifications.

Vacuum

contact wear.

See Electrical

Service Life

(Page 23).

Check contact wear and

wipe.

If wipe is too small

contact Toshiba.

Vacuum level. Apply 10kV AC

for 1 minute.

Check vacuum level by

withstand voltage test.

If breakdown occurs,

contact Toshiba.

Dust on

surface of

vacuum

interrupter

Visual inspection. Make sure there is no dust

on the surface.

Wipe with a clean, dry

cloth.

Insulating

Frame and

Flanges

Dust, foreign

matter or

damage

Visual inspection. Make sure there is no dust,

foreign matter or breakage.

Wipe with a clean, dry

cloth. If damaged,

contact Toshiba.

Control

Circuits

Auxiliary

Switch

Contact wear and wipe.

Make sure there is no dust.

Replace if wear or

damage is excessive.

See Table 1 for tightening

torque specifications

Drive unit

Visual inspection. Check for overheating and

discoloration.

Replace if damaged.

Wiring

Visual inspection.

Tighten using a

screwdriver.

Check for discoloration and

tightness.

Repair if disconnected.

Tighten if loose. See

Table 1 for tightening

torque specifications.