Page 26

MAINTENANCE

RECOMMENDED INSPECTION AND

MAINTENANCE TYPES

NOTE:

Refer to the SAFETY section of this

manual for important information.

A. Acceptance Inspection

This inspection confirms that the circuit

breaker unit is complete, correct as specified,

and undamaged from shipment. The

procedure for this inspection is outlined in the

RECEIVING, INSPECTION AND HANDLING

section of this manual.

B. Patrol Inspection

Inspection is made of the condition of the

circuit breaker while it is energized. Check

that no unusual sounds or smells exist

externally.

Inspection Frequency: Once every 6 months

C. Periodic Inspection

Inspection is performed wth the circuit

breaker de-energized. The lubrication of

sliding and rotating parts is checked and the

mechanism is lubricated if needed.

Inspection Frequency: Once every 1-3 years

or every 3000 operations (normal). Once

every 6 years (detailed).

Refer to Table 2 for the schedule of Periodic

Inspections.

D. Unscheduled Inspection

Inspections are implemented as required.

Inspection Frequency: As needed

NOTE:

The inspection frequency and points

to be inspected may vary from the

above recommendations depending

on the status of use, frequency of

switching, amount of current

interrupted and other factors.

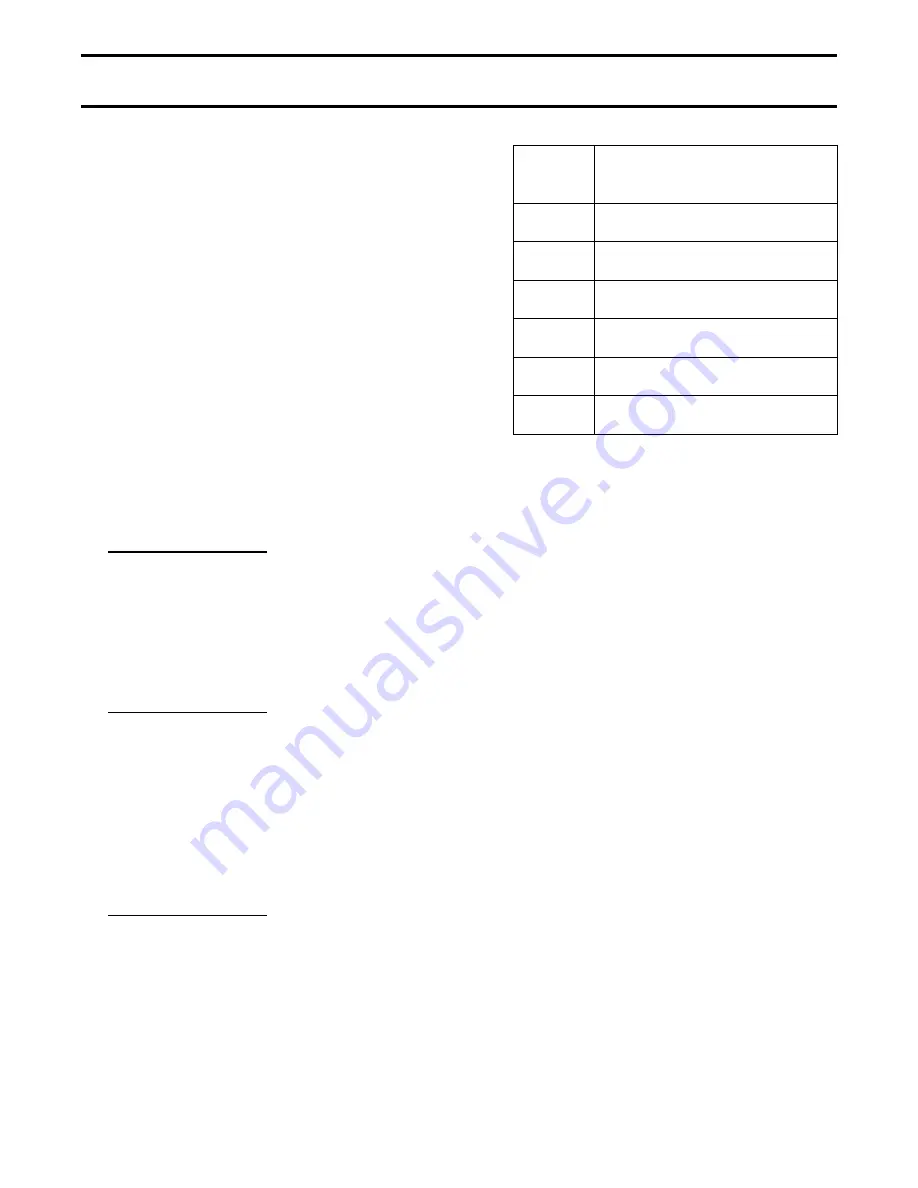

Table 1 Tightening Torques

Screw

Nominal

Dia.

Tightening Torque

M4

15-20 kgf-cm

13-17 in-lb

M5

30-40 kgf-cm ()

26-34 in-lb

M6

50-65 kgf-cm ()

43-56 in-lb

M8

120-150 kgf-cm ()

9-11 ft-lb

M10

250-315 kgf-cm ()

18-23 ft-lb

M12

450-565 kgf-cm ()

32-41 ft-lb