Page 28

MAINTENANCE

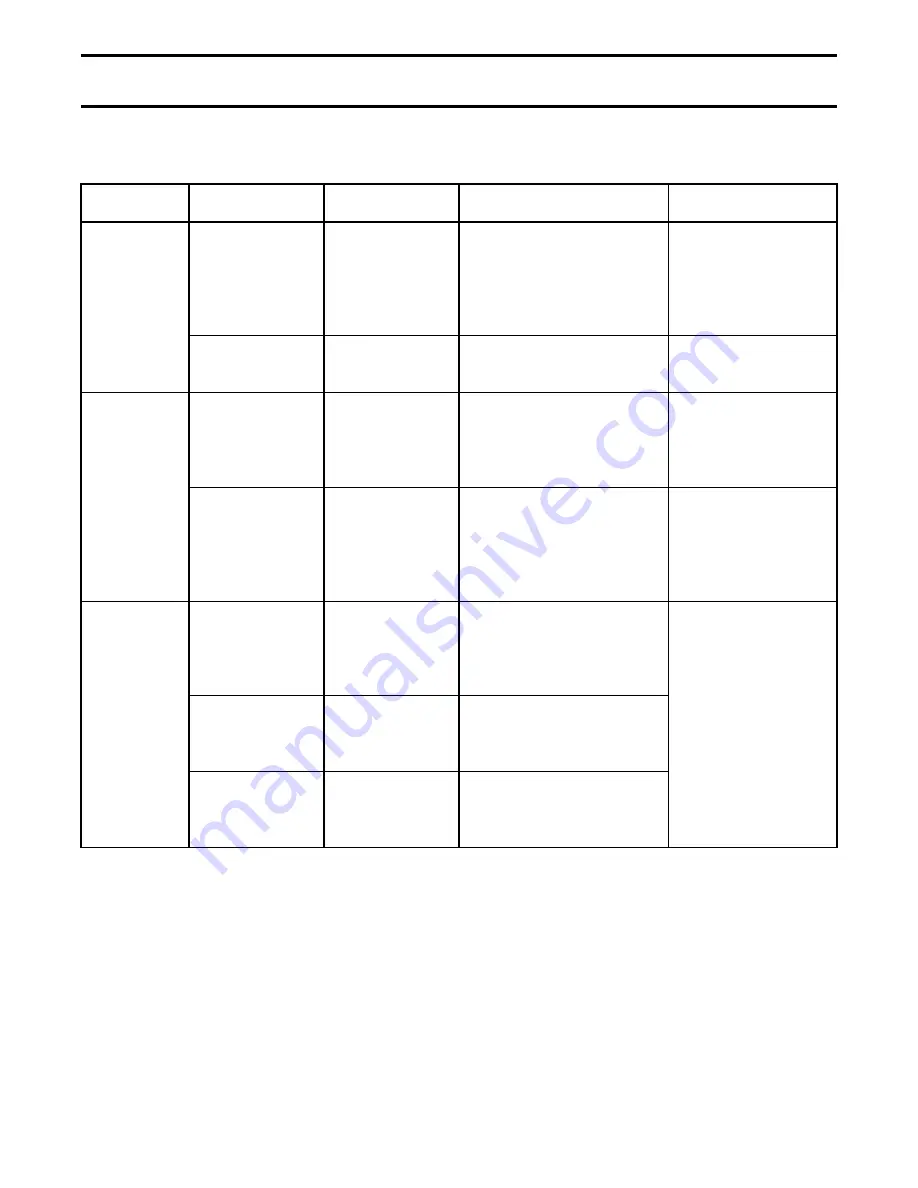

Table 2. Check Points for Inspection (cont’d)

Check Point

Check Item

Check Method

Criteria

What to do

Auxiliary

Switch

Terminals loose

or disconnected

Visual

inspection.

Tighten using a

screwdriver.

Make sure terminals are

not loose or disconnected.

Repair if

disconnected.

Tighten if loose.

See Table 1 for

tightening torques.

Case/contacts

Visual

inspection.

Make sure there is no

damage or warping.

Replace if damaged

or warped.

Control

Circuits

Smooth

movement of

motor charging

mechanism

Energize the

control circuit.

Breaker (motor-operated

type) should charge

quickly and smoothly.

If the circuit fails to

operate, check the

cause and repair.

Terminals loose

or disconnected

Visual

inspection.

Tighten using a

screwdriver.

Make sure terminals are

not loose or disconnected.

Repair if

disconnected.

Tighten if loose.

See Table 1 for

tightening torques.

Insulation

Resistance

Measure-

ment

Meaure main

circuit to ground

Megger test at

1000V.

Resistance should be

500M

Ω

or greater.

Meaure

between main

circuit terminals

Megger test at

1000V.

Resistance should be

100M

Ω

or greater.

Meaure control

circuits to

ground

Megger test at

500V.

Resistance should be

2M

Ω

or greater.

If the insulation

resistance is low,

wipe off the vacuum

interrupter and other

insulation surfaces

with a clean dry

cloth and then

repeat the test.