8

90°

A

Die

Pipe

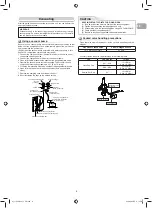

Refrigerant Piping Connection

1. Cut the pipe with a pipe cutter.

2. Insert a

fl

are nut into the pipe and

fl

are the pipe.

•

Projection margin in

fl

aring : A (Unit : mm)

Rigid (clutch type)

Imperial (wing nut type)

Outer dia. of copper pipe

R410A

Ø6.35

1.5 to 2.0

Ø12.70

2.0 to 2.5

Outer dia.

of copper pipe

R410A tool used

Conventional tool

used

Ø6.35

0 to 0.5

1.0 to 1.5

Ø12.70

0 to 0.5

1.0 to 1.5

Flaring

Obliquity

Roughness

Warp

Installation Place

• A place which provides the spaces around the outdoor unit as shown in

the diagram

• A place which can bear the weight of the outdoor unit and does not allow

an increase in noise level and vibration

• A place where the operation noise and discharged air do not disturb your

neighbors

• A place which is not exposed to a strong wind

• A place free of a leakage of combustible gases

• A place which does not block a passage

• When the outdoor unit is to be installed in an elevated position, be sure to

secure its feet.

• A place where the drain water does not raise any problems

CAUTION

1. Install the outdoor unit without anything blocking the air discharging.

2. When the outdoor unit is installed in a place always exposed to strong

wind like a coast or on a high storey of a building, secure the normal fan

operation using a duct or a windshield.

3. In particularly windy areas, install the unit such as to avoid admission of

wind.

4. Installation in the following places may result in trouble.

Do not install the unit in such places.

• A place full of machine oil

• A saline-place such as the coast

• A place full of sul

fi

de gas

• A place where high-frequency

waves are likely to be generated

as from audio equipment, welders,

and medical equipment

Strong

wind

Incused line

Flare at hydro

unit side

Flare at outdoor

unit side

Flare nut

Half union

Externally

threaded side

Internally

threaded side

Use a wrench to secure.

Use a torque wrench to tighten.

CAUTION

Align the centers of the connecting pipes and tighten the

fl

are nut as far as

possible with your

fi

ngers. Then tighten the nut with a spanner and torque

wrench as shown in the

fi

gure.

Tightening connection

Do not apply excess torque. Otherwise, the nut may crack depending on

the conditions.

(Unit : N·m)

Outer dia. of copper pipe

Tightening torque

Ø6.35 mm

14 to 18 (1.4 to 1.8 kgf·m)

Ø12.70 mm

50 to 62 (5.0 to 6.2 kgf·m)

•

Tightening torque of

fl

are pipe connections

The operating pressure of R410A

is higher than that of R22 (approx.

1.6 times). It is therefore necessary

to

fi

rmly tighten the

fl

are pipe

connecting sections (which connect

the hydro and outdoor units) up to the

speci

fi

ed tightening torque. Incorrect

connections may cause not only a

gas leakage, but also damage to the

refrigeration cycle.

1. How to shape the pipes

Shape the pipes along the incused line on

the outdoor unit.

2. How to

fi

t position of the pipes

Put the edges of the pipes to the place with

a distance of 85 mm from the incused line.

Shaping pipes

Refrigerant pipe

H: max. ±10 m (above / below)

L: max. 15 m, min 5 m

15 m chargeless

Hydro Unit

Outdoor unit

15 m chargeless

L

H

Refrigerant pipe length

01_1120551201-1 EN.indd 8

01_1120551201-1 EN.indd 8

5/18/2560 BE 3:12 PM

5/18/2560 BE 3:12 PM