6F8A0917

- 34 -

6. Operation

Do not touch the LF232 main body when

high

temperature fluid

is being measured.

DON’T

The fluid raises the main body

temperature and can cause

burns

when touched.

For operation, follow the procedure described below.

Inspection for each part

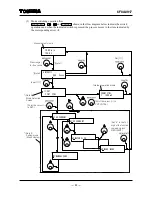

Is the wiring and connection between the detector and converter correct?

Is the wiring between the converter and related instruments correct?

Isn’t tightening of connection between the detector and the mating pipe

forgotten?

Is the direction of arrow of the detector in accordance with the direction of

actual fluid?

Are the detector and the converter grounded securely?

Is the converter cover securely tightened?

Check the items above.

Introducing water

Let the fluid go through and fill the detector pipe. (Note)

When the detector pipe is filled with fluid, stop the fluid and keep it still.

In the case of the flowmeter which is partially filled pipes type, please let a fluid

stand still at water level high as possible more than water level 30%.

Applying power supply

Is the power supply as specified?

Checking the converter settings

* See 7. “Display and Controls,” 8. “Parameter Settings/Adjustment,” and 11.

“Communications Function.”

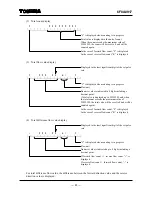

Zero adjustment

Wait for 30 minutes to warm up the flowmeter. Then perform zero adjustment.

(Check that the fluid remains still)

* See 8.5.1 “Still Water Zero Adjustment.”

Operation

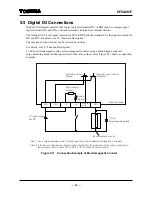

After checking the items and performing adjustment listed above, let the fluid go through the detector

pipe. Then the outputs such as current output (4 to 20mADC) directly proportional to the flow rate can

be obtained.