3

1.

SUPER MULTI SYSTEM BASIC COMPONENTS ....................................................................................4

2.

OUTLINE OF CONTROL SYSTEM ...........................................................................................................6

3.

SPECIFICATIONS .....................................................................................................................................8

4.

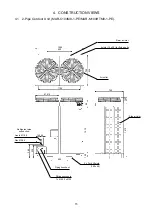

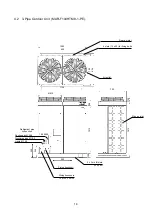

CONSTRUCTION VIEWS .......................................................................................................................15

5.

WIRING DIAGRAMS ...............................................................................................................................19

6.

REFRIGERANT CYCLE DIAGRAMS ......................................................................................................28

7.

SELF DIAGNOSTIC DISPLAY INFORMATION ......................................................................................31

8.

FAULT CODE DISPLAY INFORMATION.................................................................................................46

9.

CONTROL FEATURES ...........................................................................................................................53

10. VALVE & SENSOR FUNCTION AND OPERATION ................................................................................55

11. PRESSURE TEST, EVACUATION AND DEHYDRATION .......................................................................59

12. ADDITIONAL REFRIGERANT.................................................................................................................60

13. EXPLODED VIEWS AND SERVICE PARTS LISTS ...............................................................................61

CONTENTS

SUMMARY

The units referred to within this manual conform with the protection requirements of Directives

89/336/EEC Electromagnetic Compatibility and 73/23/EEC Low voltage.

Operating conditions of the unit are as follows:

Outdoor temperature

-5 ~ 43°C

Cooling

-10 ~ 21°C

Heating

(MAR-M104HTM8-1-PE, MAR-F104HTM8-1-PE)

Room Temperature

18 ~ 32°C

Cooling

15 ~ 29°C

Heating

(MAR-M104HTM8-1-PE, MAR-F104HTM8-1-PE)

Room humidity

< 80%

Cooling

Note 1:

Cooling capacity is rated at the following temperature conditions:

Indoor air inlet temperature

27°C DB, 19°C WB.

Outdoor air inlet temperature 35°C DB.

Note 2:

Heating capacity is rated at the following temperature conditions:

Indoor air inlet temperature

20°C DB.

Outdoor air inlet temperature 7°C DB, 6°C WB.

Note 3:

For details on the Outdoor unit installation, the Indoor units or Remote Controllers refer to

the relevant literature. i.e. Installation instructions supplied with the units or Service

manuals relevant to the indoor units.

Note 4:

Operatives handling refrigerants must be suitably qualified in accordance with local and

national codes of practice and statutory requirements.

Note 5:

Legislation may regulate the removal of waste refrigerant from the systems. We advise

awareness of any regulations and duty of care. Waste refrigerant must NEVER be discharged to

atmosphere.

Note 6:

Electrical work should be in accordance with all relevant codes of practice and should be

carried out by suitably qualified personnel.

Note 7:

Metric / Imperial pipe conversion.

Diameter (mm)

6.4

9.5

12.7

15.9

19.0

22.0

28.6

Nominal diameter (inch)

1

/

4

3

/

8

1

/

2

5

/

8

3

/

4

7

/

8

1

1

/

8

Note 8:

Within this manual, O/D = Outdoor unit, M/C = Multi controller, I/D = Indoor unit,

R/C = Remote controller, D.O.L. = Direct on-line compressor.

Summary of Contents for MAR-C104M8-1-PE

Page 2: ......

Page 22: ......

Page 58: ...61 13 EXPLODED VIEWS AND SERVICE PARTS LISTS 13 1 Outdoor Unit MAR C104M8 1 PE ...

Page 60: ...63 13 3 Outdoor Units MAR M104HTM8 1 PE MAR F104HTM8 1 PE ...

Page 63: ...66 13 6 Outdoor unit electrical parts assembly MAR C104M8 1 PE ...

Page 65: ...68 MAR M104HTM8 1 PE MAR F104HTM8 1 PE ...

Page 72: ......