– 14 –

Outdoor Unit

Installation Manual

EN

Outdoor Unit

Installation Manual

Airtight test

Before starting an airtight test, further tighten the spindle valves on the gas side and liquid side.

Pressurize the pipe with nitrogen gas charged from the service port to the design pressure to conduct the airtight

test.

After the airtight test is completed, evacuate the nitrogen gas.

• Apply pressure from the service ports of the packed valves (or ball valves) at liquid side, discharge gas side and

suction gas side.

• An air tight test can be only performed to the service ports at liquid side, discharge gas side, and suction gas

side of the outdoor unit.

• Close fully valves at liquid side, discharge gas side, and suction gas side. As there is possibility that nitrogen gas

enters in the refrigerant cycle, re-tighten the valve rods before applying pressure.

(Re-tightening of the valve rods are unnecessary for valves at discharge gas side because they are ball valves.)

• For each refrigerant line, apply pressure gradually with steps at liquid side, discharge gas side, and suction gas

side.

Apply pressure to suction gas side, discharge gas side, and liquid side.

REQUIREMENT

Do not use “Oxygen”, “Flammable gas” and “Noxious gas” in an airtight test.

To detect a gross leakage

1. Apply pressure 0.3 MPa (3.0 kg / cm

2

G) for 3 minutes or more.

2. Apply pressure 1.5 MPa (15 kg / cm

2

G) for 3 minutes or more.

To detect a slow leakage

3. Apply pressure 3.73 MPa (38 kg / cm

2

G) for approx. 24 hours.

• Check pressure down.

No pressure down: Accepted

Pressure down: Check the leaked position.

NOTE

However, if the environmental temperature changes from the moment of applying pressure to 24 hours after that, the

pressure will change by about 0.01 MPa (0.1 kg / cm²G) per 1 °C. Consider the pressure change when checking the

test result.

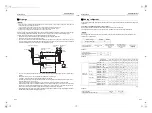

Main pipe

Brazed

Fully closed

Ball valve fully closed

(gas side)

Outdoor unit

Service port

Service port

Packed valve fully closed

(liquid side)

Ø6.4

Copper pipe

Ø6.4

Copper pipe

Nitrogen gas

Reducing

valve

Gauge

manifold

High pressure

guage

Low pressure

guage

Connected to indoor unit

REQUIREMENT

When pressure decrease is detected in steps 1-3, check the leakage at the connecting points.

Check the leakage using a foaming agent or other measures and seal the leak with re-brazing, flare retightening or other

methods. After sealing, execute an airtight test again.

27-EN

28-EN

+00EH99883601_00Ta.book Page 14 Thursday, September 8, 2011 4:34 PM