– 26 –

Outdoor Unit

Installation Manual

EN

Outdoor Unit

Installation Manual

▼

To change all the indoor unit addresses using an arbitrary wired remote controller.

(The method is available when the addresses have already been set automatically.)

(When communication wirings of 2 or more refrigerant lines are interconnected for central control)

NOTE

You can change the addresses of indoor units in each refrigerant line using an arbitrary wired remote controller.

* Enter the address check / change mode and change the addresses.

If no number appears on UNIT No., no outdoor unit exists on the line. Push

button and select another line

following step

2

.

(Execute it while the units are stopped.)

1

Push and hold the TIME

and

buttons at the same time for more than 4 seconds.

At first, the line 1 and CODE No.

(Address Change) are indicated on the LCD display.

2

Push

(left side of the button) and

buttons repeatedly to select a system address.

3

Push the

button.

• The address of one of the indoor units connected to the selected refrigerant line is indicated on the LCD

display and the fan and louvers of the unit are activated.

At first, the current indoor unit address is displayed in

SET DATA

.

(No system address is indicated.)

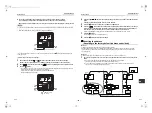

3

1

2

ON / OFF

TEMP.

TIME

SET CL

FILTER

RESET TEST

TIMER SET

CODE No.

UNIT No.

SETTING

DATA

SET

R.C.

No.

Cancels the line selection

CL

TEST

SWING/FIX

SET

4

8

5, 7

6

ON / OFF

TEMP.

TIME

SET CL

FILTER

RESET TEST

TIMER SET

CODE No.

UNIT No.

SETTING

DATA

SET

R.C.

No.

Press to finish

setting.

Finish

4

Push the TIME

/

buttons repeatedly to change the value of the indoor unit address in SET

DATA.

Change the value in SET DATA to that of a new address.

5

Push the

button to confirm the new address on SET DATA.

6

Push the

button (left side of the button) repeatedly to select another address to change.

Each time you push the button, the indoor unit numbers in a refrigerant line are indicated one

after another. Only the fan and louvers of the selected indoor unit are activated.

Repeat steps

4

to

6

to change the indoor unit addresses so as to make each of them unique.

7

Push the

button.

(All the segments on the LCD display light up.)

8

Push the

button to finish the procedure.

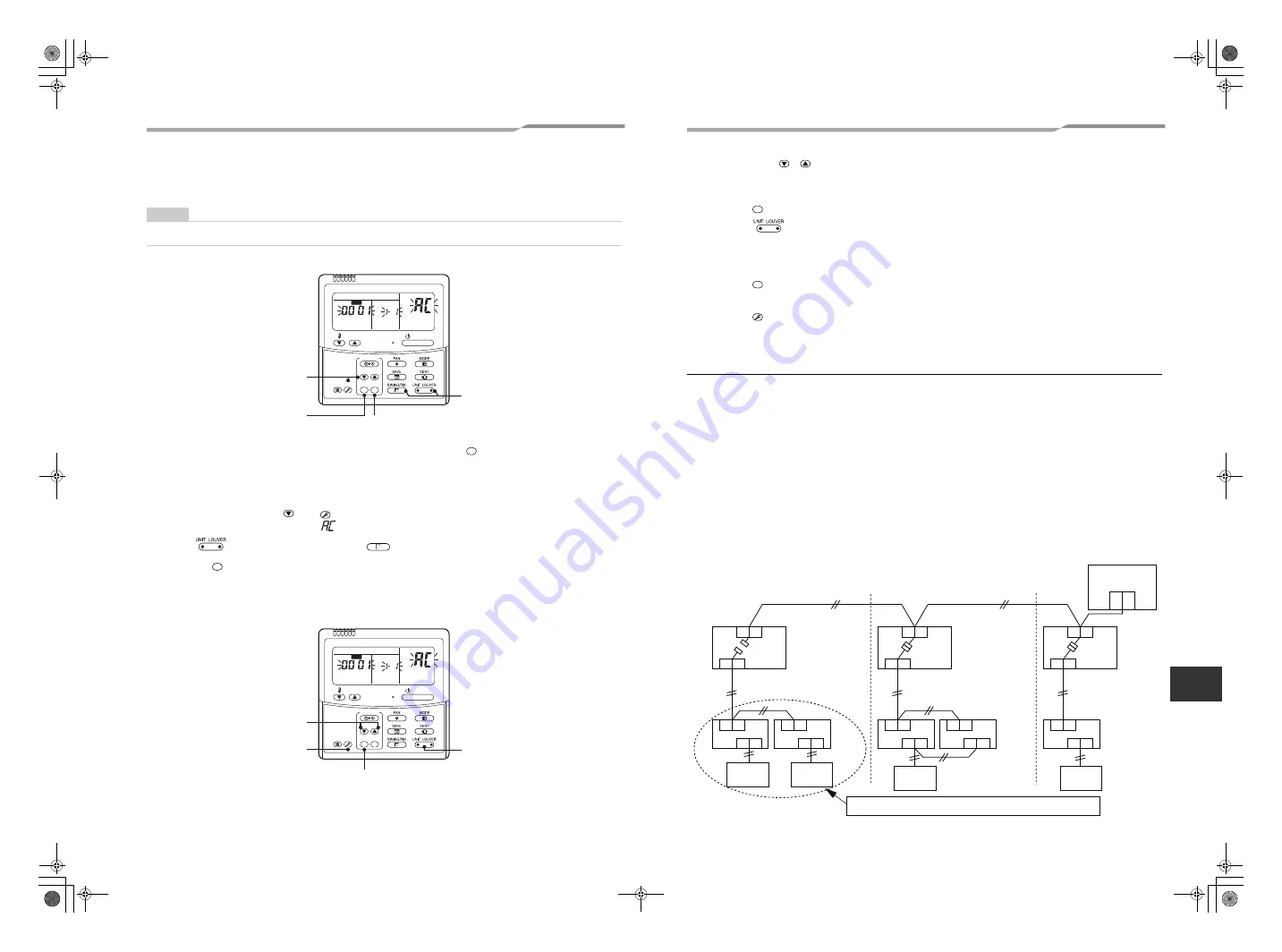

Resetting the address

(Resetting to the factory default (address undecided))

Method 1

Clearing each address separately using a wired remote controller.

Set the system address, indoor unit address and group address to “0099” using a wired remote controller.

(For the setting procedure, refer to the address setting procedures using the wired remote controller on the

previous pages.)

Method 2

Clearing all the indoor unit addresses on a refrigerate line at once from the outdoor unit.

1

Turn off the refrigerant line to reset to the factory default and set the outdoor unit of the line as

below.

1) Disconnect the relay connectors between the [U1, U2] and [U3, U4] terminals.

(Leave them as they are if they have already been disconnected.)

2) Turn on dip switch 2 of SW30 on the interface P.C. board of the outdoor unit if the switch is OFF.

(Leave it as it is if it has already been set to ON.)

SET

SET

TEST

U3 U4

U1 U2

U1 U2

A B

U1 U2

A B

U3 U4

U1 U2

U1 U2

A B

U1 U2

A B

U3 U4

U1 U2

U1

U3

U2

U4

U1 U2

A B

Central controller

Outdoor

unit

Remote

controller

Remote

controller

Remote

controller

Remote

controller

Indoor units to have their addresses initialized

Outdoor

unit

Outdoor

unit

51-EN

52-EN

+00EH99883601_00Ta.book Page 26 Thursday, September 8, 2011 4:34 PM